Introduction

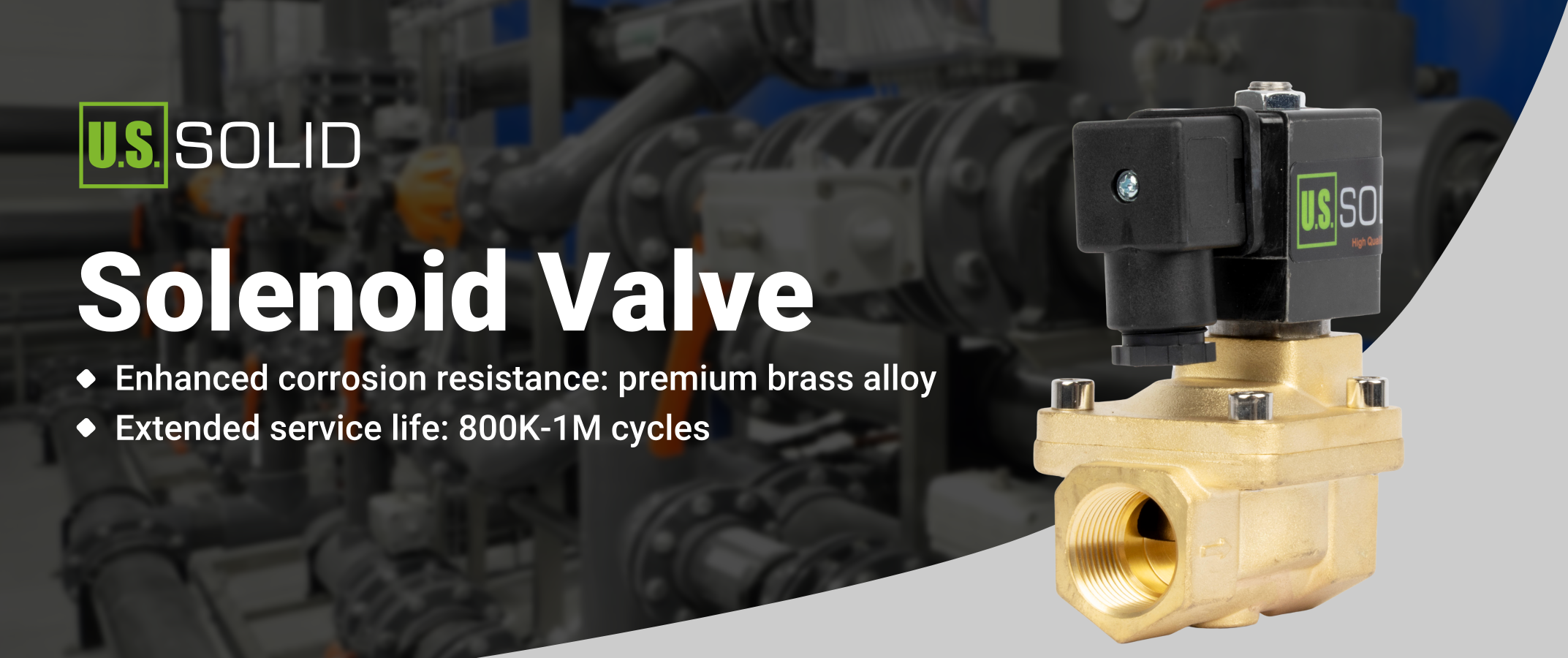

A solenoid valve is a key component in fluid control systems, used in applications like irrigation, combustion engines, and pneumatic systems. It uses an electrical signal to activate a solenoid coil, generating a magnetic field that moves a plunger to open or close the valve. This allows for quick and precise control of fluid or gas flow, making solenoid valves essential for efficient system operation.

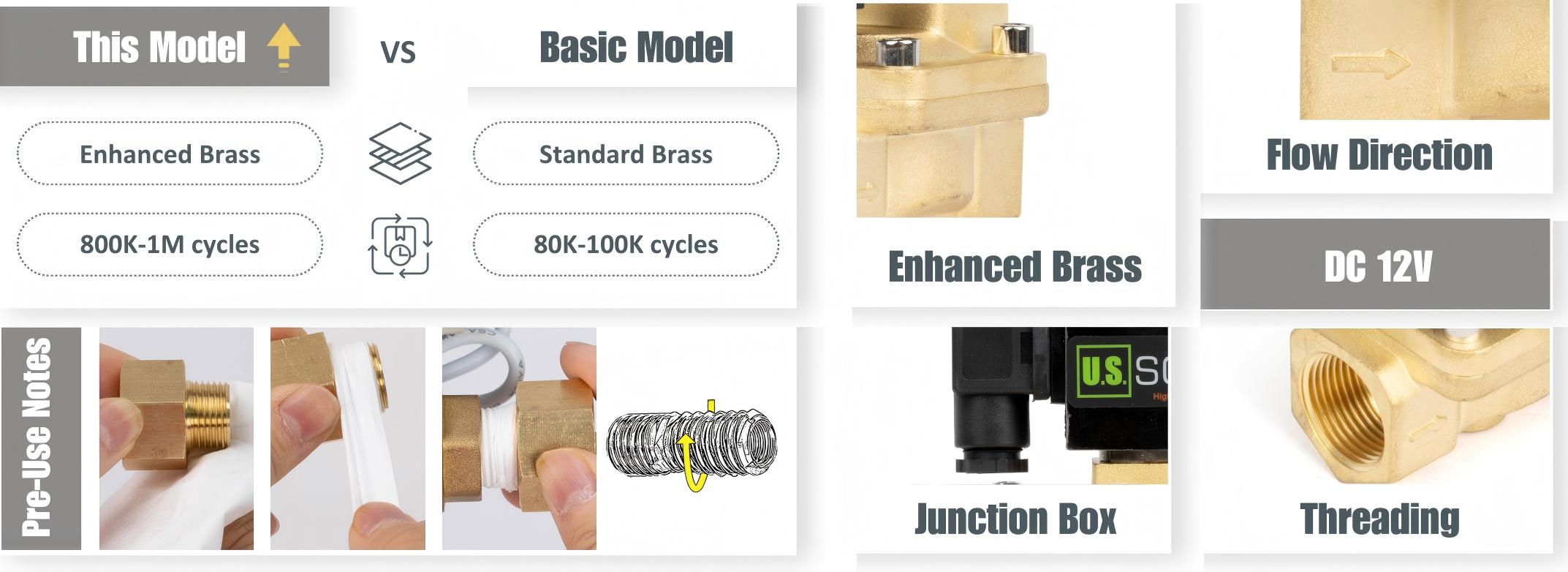

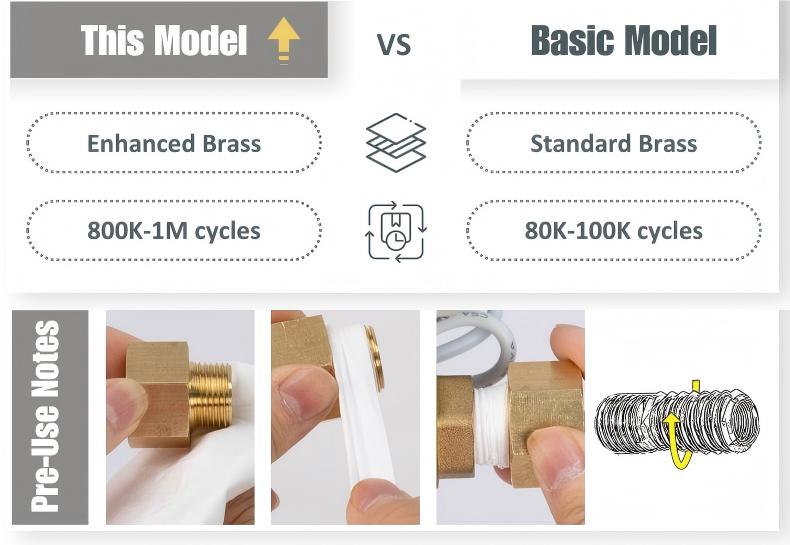

As an enhanced version of standard brass solenoid valves, this series features premium brass alloy with an optimized composition for superior material quality and corrosion resistance. Additionally, structural refinements and precision engineering extend its service life to 800,000-1,000,000 cycles—10x that of conventional solenoid valves—significantly boosting durability and overall performance.

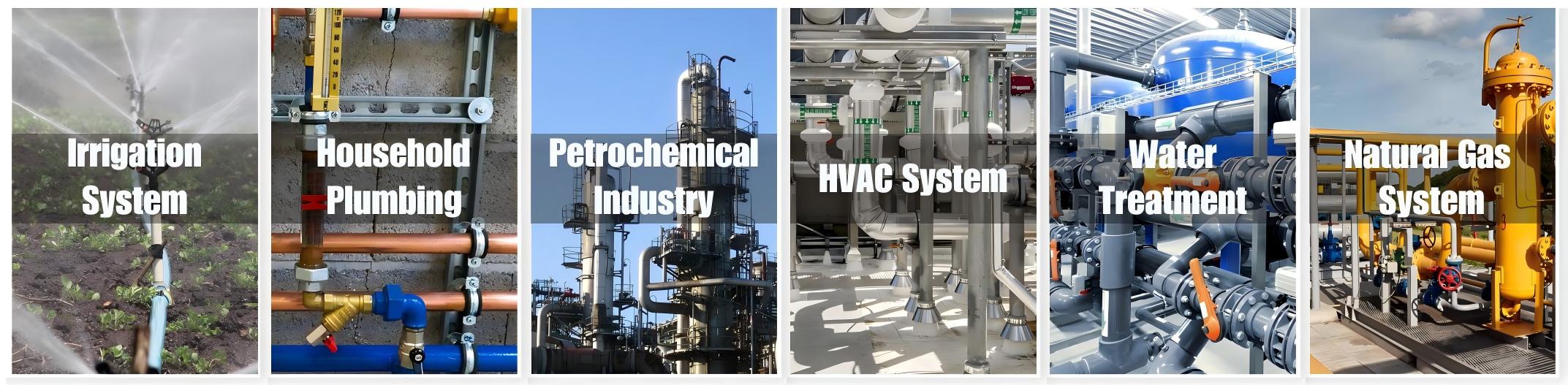

Applications

Features

- Normally Closed: Closed when unpowered, opens when energized.

- NPT / G Threading: NPT (National Pipe Taper) and G (BSPP) to accommodate diverse global specifications, ensuring a secure seal with teflon tape.

- Enhanced Valve Body Material: Constructed from an enhanced brass alloy, the valve delivers exceptional durability and corrosion resistance, withstanding harsh industrial conditions. Note: Contains lead – not suitable for drinking water applications.

- 800K-1M Cycle Long Lifespan: Features 316 stainless steel diaphragm reinforcement and precision spring, ensuring ultra-long reliable use vs. standard valves.

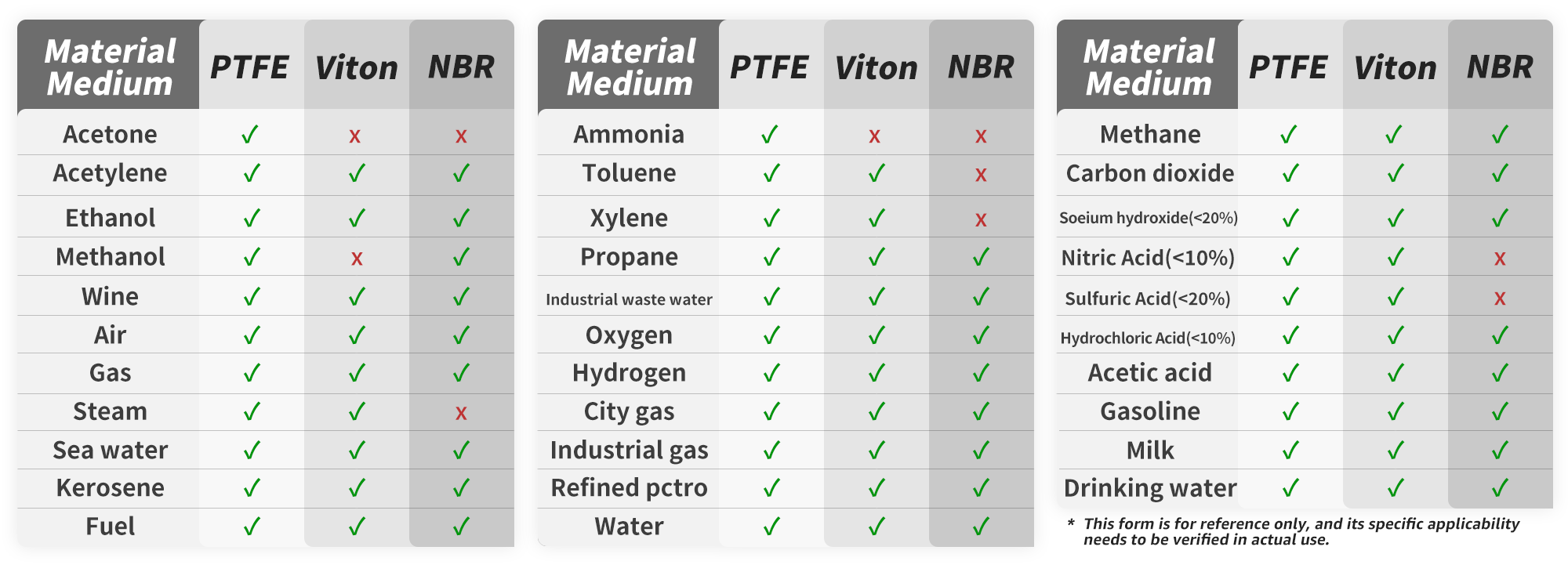

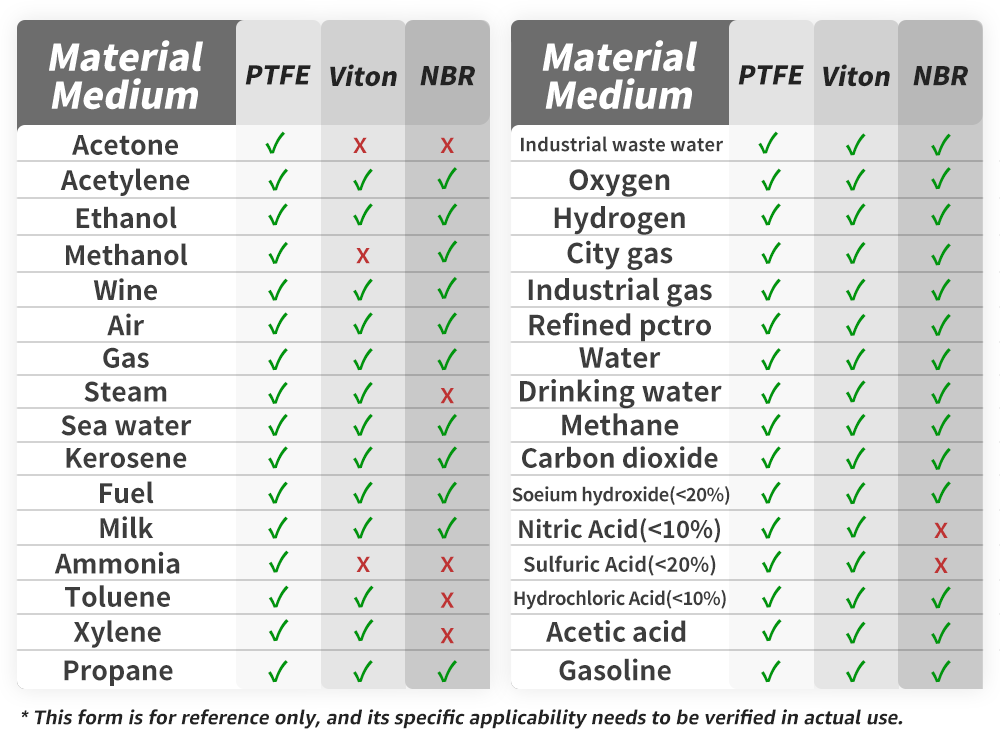

- NBR Sealing: Equipped with NBR sealing material (compatible with water, air, oils, mild chemicals).

User Manual

To learn how to use this product, please refer to the user manual.

Technical Data

| Model | USS-SV00128 | Port Size | 1" | ||

| Thread Type | NPT/G | Body Material | Brass | ||

| Operation Type | Pilot | Wiring Type | Junction Box | ||

| Operation Mode | Normally Closed | Flow Aperture | 25 mm | ||

| Flow value | 12 Cv | Gasket/Diaphragm/Seal | NBR | ||

| Life Expectancy | 800K-1M Cycles | Rated Voltage | DC 12V | ||

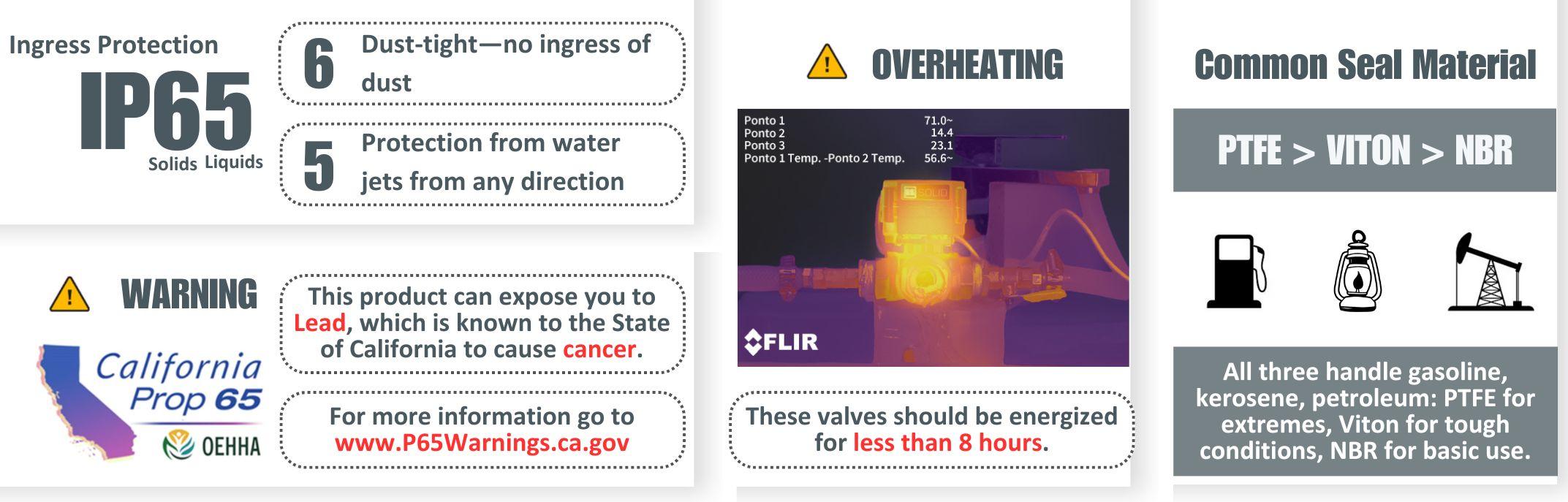

| IP Rating | IP65 | Power | 20W | ||

| Operating Temperature | 23℉-176℉(-5℃-80℃) | Suitable Liquid Viscosity | 20 cst Below | ||

| Operating Pressure | 0.5-16 Bar | Suitable Media | Air, water, diesel oil, kerosene, etc. | ||

| Net Weight | 3.37 lbs | Package Dimensions | 5.12"x3.94"x3.15" | ||

*To view the full table on mobile, please swipe left or right on the screen.

FAQ

Problem 1: What are the most significant differences between this series and standard brass solenoid valves?

Enhanced Brass Body - Superior durability. Ultra-Long Lifespan - 800K-1M cycles, achieved with a 316 stainless steel diaphragm.

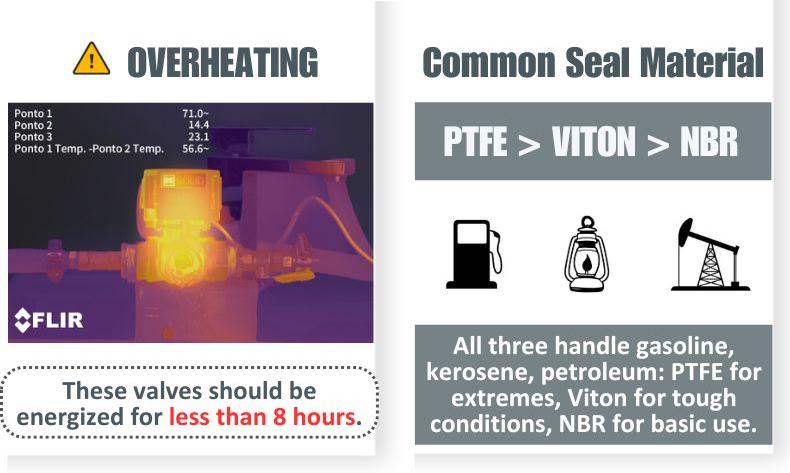

Problem 2: Can these solenoid valves be used continuously for extended periods?

These valves should be energized for less than 8 hours. While most do not exceed 18W of power, the coils are in a contained area and can burn out if energized for too long. We recommend using a computer fan to keep the coil cool if continuous operation is necessary.

Problem 3: What is the service life of this valve series?

It has an ultra-long lifespan of 800,000 to 1 million cycles, which is much longer than standard valves. This is achieved by its 316 stainless steel diaphragm reinforcement and precision spring.

Problem 4: Can this be used for Drinking Water?

NO. This solenoid valve is made of brass, which contains lead, should not be used for drinking water.

Problem 5: Can it be used outdoors?

While the solenoid valves have an IP65 rating, making them resistant to water spray, it is recommended to enclose the valve in a protective housing if permanently installed outdoors to ensure long-term durability.

Problem 6: What does the arrow on the valve body indicate?

The arrow on the valve indicates the flow direction. Most U.S. Solid valves are unidirectional, meaning they are designed to operate correctly only when fluid flows in the direction of the arrow. If installed in the opposite direction, the valve may not function properly (e.g., a Normally Closed valve may fail to close).

Problem 7: What is the difference between N.C. (Normally Closed) and N.O. (Normally Open)?

- Normally Closed (NC): Valve remains closed when power is off, opening only when energized. Ideal for fail-safe closed applications.

- Normally Open (NO): Valve remains open when power is off, closing only when energized. Ideal for fail-safe open applications.

Precautions

- It is recommended to filter the fluid before use to prevent impurities from blocking the valve, which could lead to incomplete closure.

- Flow Direction: During installation, ensure the arrow on the valve body aligns with the medium's flow direction. If reverse pressure is possible, install a check valve to prevent backflow.

- To ensure optimal performance and extend the solenoid valve's lifespan, install it horizontally with the coil facing vertically upward. Avoid vertical or backward coil orientation.

- The solenoid valve generates heat during operation. Avoid direct contact with your hands.

- Solenoid valves that have been out of service for an extended period should be cleaned to remove any accumulated impurities or condensation before use.

- To ensure a secure seal, always use Teflon tape when connecting NPT / G threads.

*Important: Check marks (√) denote conditional suitability only; crosses (×) indicate complete incompatibility.