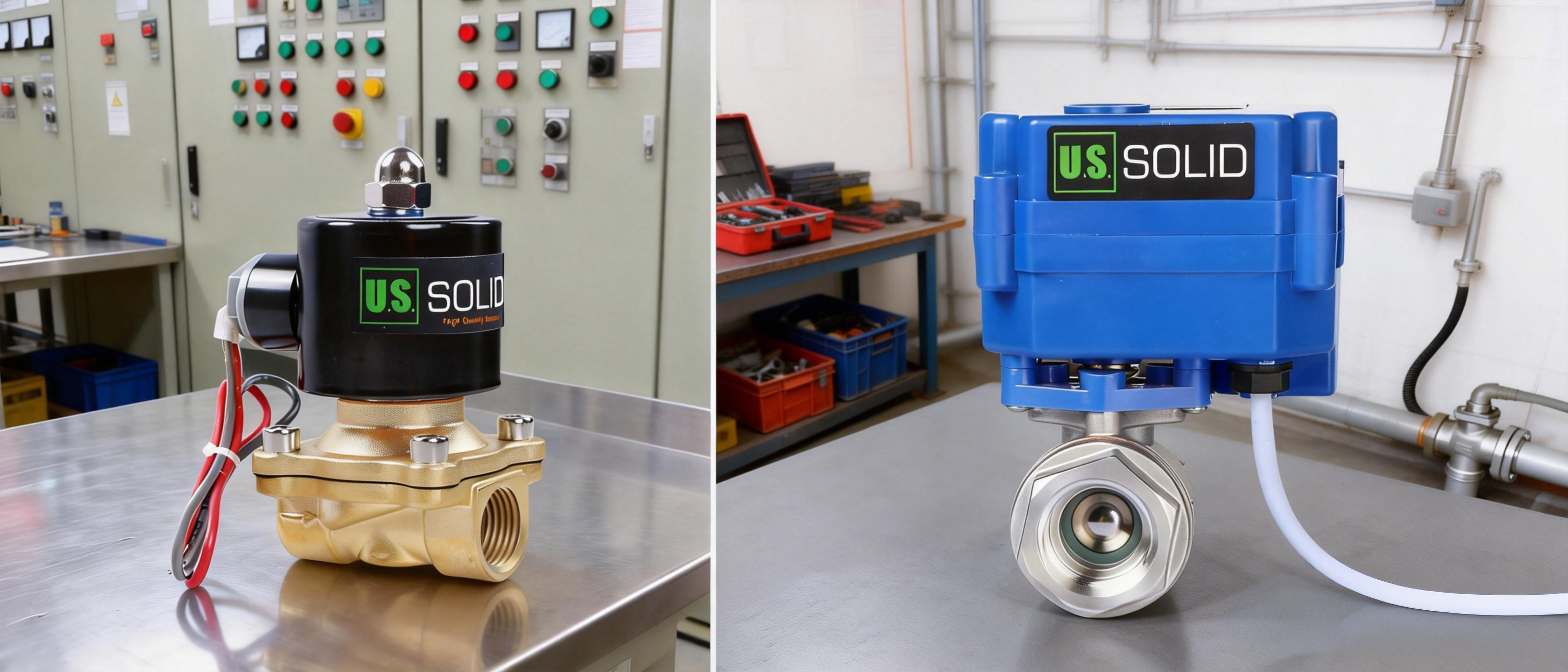

Ball Valve vs Solenoid Valve: Which One Is Right for Your Project?

Deel

Choosing the right valve for your piping system can be the difference between a high-performing setup and a maintenance nightmare. While both Motorized Ball Valves and Solenoid Valves control flow, they operate on fundamentally different mechanical principles, each suited for specific tasks.

In this guide, we’ll dive into the technical and practical differences to help you make an informed decision for your application.

1. How They Work

Solenoid Valves: The Speed Kings

A solenoid valve is an electromechanical device. An electric current creates a magnetic field that moves a ferrous plunger to open or close the valve almost instantaneously.

Best for: Precise timing, dosage systems, or rapid-cycle irrigation.

Motorized Ball Valves: The Reliable Workhorses

These use a small electric motor to rotate an internal ball 90 degrees. This creates a "straight-through" path with zero obstruction when fully open, much like a regular pipe.

Best for: Main shut-offs, high-volume flow, and energy-efficient systems.

2. Key Decision Factors

Water Hammer & Pipe Safety

Solenoid valves snap shut in milliseconds. This sudden stop can cause "Water Hammer"—a shockwave that vibrates pipes and leads to leaks. Ball valves close gradually (3–10 seconds), protecting your plumbing.

Pressure (PSI) Requirements

Many solenoid valves require a minimum pressure differential (usually 3-5 PSI) to function. In gravity-fed systems, a solenoid might fail to open. Motorized Ball Valves work perfectly at 0 PSI.

3. Quick Comparison Table

| Feature | Solenoid Valve | Motorized Ball Valve |

|---|---|---|

| Cycle Speed | Instant (0.1s) | Gradual (3-10s) |

| Flow Path | Restricted (Orifice) | Full Port (Straight) |

| Energy Use | Higher (Needs power to stay open) | Lower (Power only when moving) |

| PSI Requirement | Usually needs > 3 PSI | Works at 0 PSI (Gravity OK) |

| Water Hammer | High Risk | Low Risk |

| Debris Tolerance | Low (Easily Clogged) | High (Self-Cleaning) |

4. Common Use Cases

Coffee machines, pneumatic tools, rapid irrigation, and gas emergency shut-off.

Main water supply, HVAC systems, solar heaters, and industrial liquid processing.

5. The Verdict

If your project requires high-speed switching and uses clean media, go with a Solenoid Valve.

However, for reliability, maximum flow, and long-term pipe safety, a Motorized Ball Valve is almost always the superior choice for modern installations.