مقدمة

صُممت صمامات الملف اللولبي التناسبية للتحكم في تدفق السوائل والغازات. يتناسب تدفقها الخارج مع إشارة التيار الداخل، مما يسمح بضبط تدفق السائل أو الغاز بسلاسة عن طريق تنظيم التيار. ونتيجة لذلك، تُستخدم صمامات الملف اللولبي التناسبية على نطاق واسع في أنظمة التحكم المختلفة ذات الحلقة المفتوحة أو المغلقة لضغط وتدفق السوائل والغازات.

تختلف هذه الصمامات من الناحية الهيكلية والتشغيلية عن صمامات الملف اللولبي التقليدية التي تعمل بنظام التشغيل والإيقاف. فعلى عكس صمامات الملف اللولبي التقليدية التي تعمل بمجرد توصيل الطاقة، تتطلب صمامات الملف اللولبي التناسبية إشارات كهربائية تناظرية أو رقمية لتحقيق خرج دقيق وقابل للتحكم.

ملاحظة الشراء

لا يعني وجود علامة "غير متوفر" هنا أن المنتج غير متاح للشراء. نظرًا للتخصص العالي للصمامات التناسبية، يتطلب الاختيار الصحيح مطابقة دقيقة لمعايير نظامك (إشارة التحكم، نطاق الضغط، نوع الوسط، إلخ). لتجنب أي عدم تطابق وضمان الأداء الأمثل، يُرجى التواصل مع خدمة العملاء أولًا إذا كنت مهتمًا. سيقوم فريقنا الفني بتأكيد الطراز المناسب لك وترتيب عملية الطلب على الفور.

التطبيقات

سمات

- خيوط NPT: خيوط NPT (الخيوط المخروطية الوطنية للأنابيب) مصممة لتلبية مختلف المواصفات العالمية، مما يضمن إحكامًا تامًا باستخدام شريط التفلون . بالنسبة للصمامات ذات خيوط G (BSPP)، يُرجى التواصل مع خدمة العملاء.

- التوصيل الكهربائي: مزود بواجهة كهربائية من نوع الشفرة 6.3 × 0.8 مم وصندوق توصيل مخصص لتوصيل الأسلاك والتركيب المرن.

- استجابة سريعة: ردود فعل سريعة وحساسة في غضون 20-40 مللي ثانية.

- التحكم الدقيق: دقة تنظيم فائقة: أقصى تخلف ≤15%، تكرار التدفق ≤1%، حساسية التحكم ≤0.1%.

- الوسائط القابلة للتطبيق: بشكل أساسي للوسائط الغازية/السائلة المحايدة؛ يسمح مانع التسرب المصنوع من الفيتون بالتوافق مع البيئات المسببة للتآكل بشكل طفيف.

- مادة جسم الصمام: فولاذ مقاوم للصدأ 316 (مقاومة عالية للتآكل، آمن للاستخدام مع المواد الغذائية، مستقر حرارياً). مناسب لتطبيقات مياه الشرب وبيئات التحكم في السوائل الصناعية القاسية.

البيانات الفنية

| حجم المنفذ | 1/8" | موصى به لـ | الغازات والسوائل المحايدة |

| التوصيل الكهربائي | طرفية شفرة 6.3 × 0.8 مم | فئة عزل الملف | ح |

| صندوق التوصيل متضمن | نعم | وحدة تحكم مرفقة | لا |

| نوع الخيط | معاهدة عدم انتشار الأسلحة النووية | نطاق درجة الحرارة (متوسط) | من 14 درجة فهرنهايت إلى 194 درجة فهرنهايت (من -10 درجة مئوية إلى 90 درجة مئوية) |

| مادة الجسم | الفولاذ المقاوم للصدأ 316 | نطاق درجة الحرارة (المحيطة) | من 32 درجة فهرنهايت إلى 131 درجة فهرنهايت (من 0 درجة مئوية إلى 55 درجة مئوية) |

| مقاومة | 96 أوم | عملية | مباشر |

| الجهد االكهربى | تيار مستمر 24 فولت | تصنيف IP | IP65 |

| أقصى تيار تشغيل | 0.2 أمبير | إشارة الإدخال | تعديل عرض النبضة |

| أقصى قوة | 6 واط | تردد تعديل عرض النبضة | 1200-2000 هرتز |

| مادة مانعة للتسرب | فيتون | دقة التخلف | ≤15% |

| لا/لا | مغلق عادةً | دقة التكرار | ≤1% |

| زمن الاستجابة | 20-40 مللي ثانية | حساسية | ≤0.1% |

*لعرض الجدول كاملاً على الهاتف المحمول، يرجى التمرير لليسار أو لليمين على الشاشة.

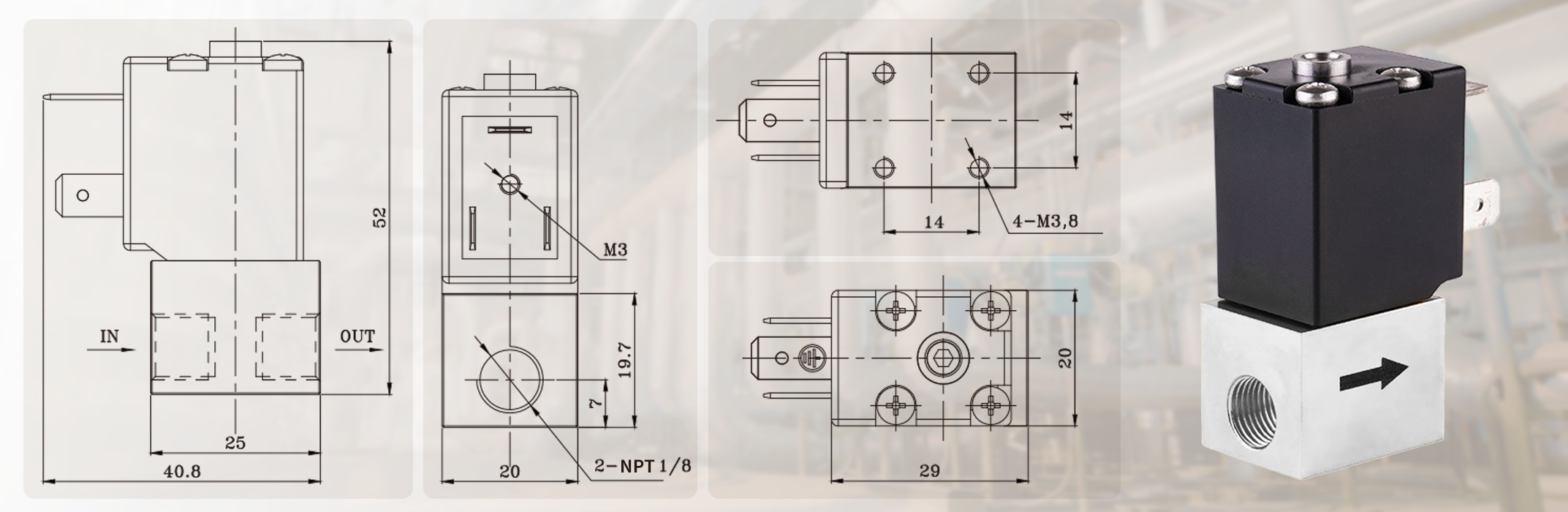

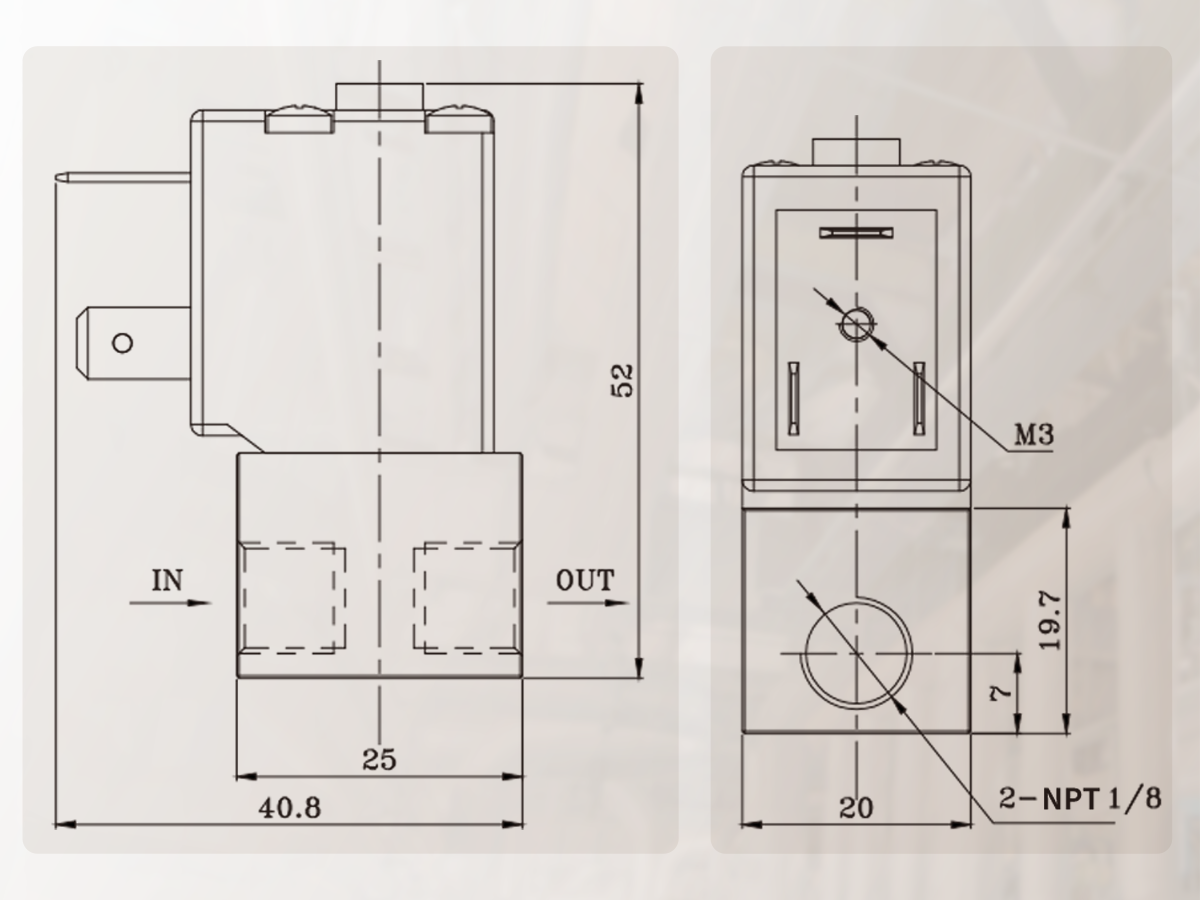

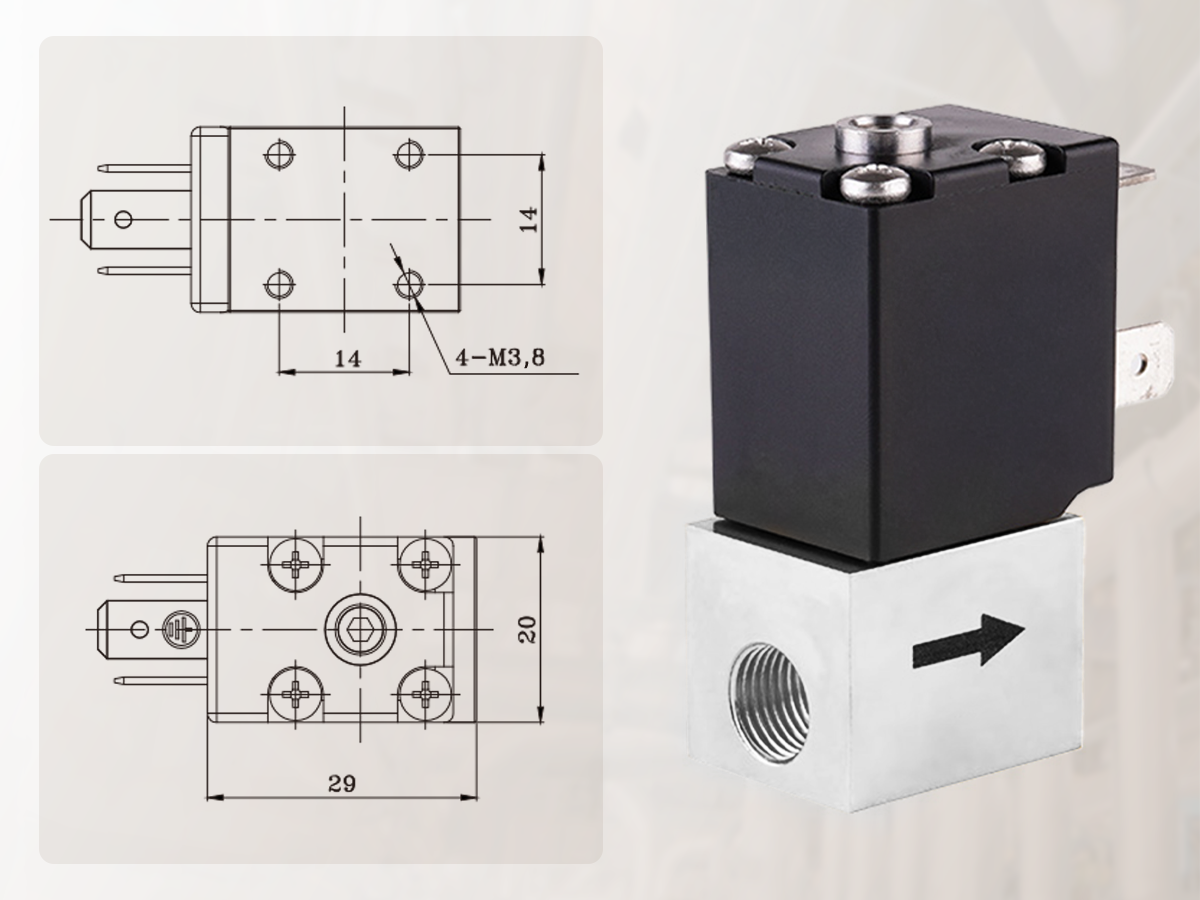

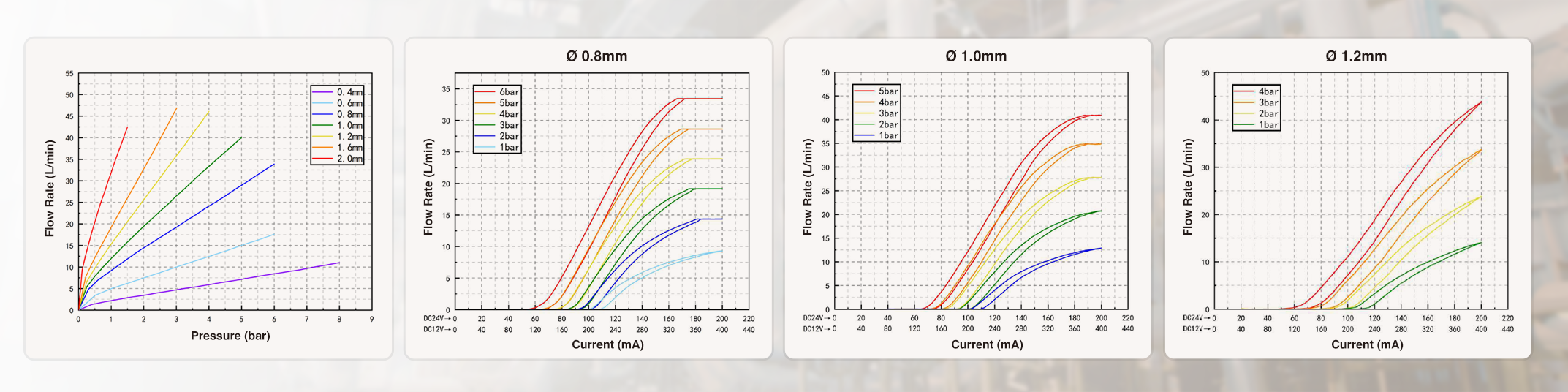

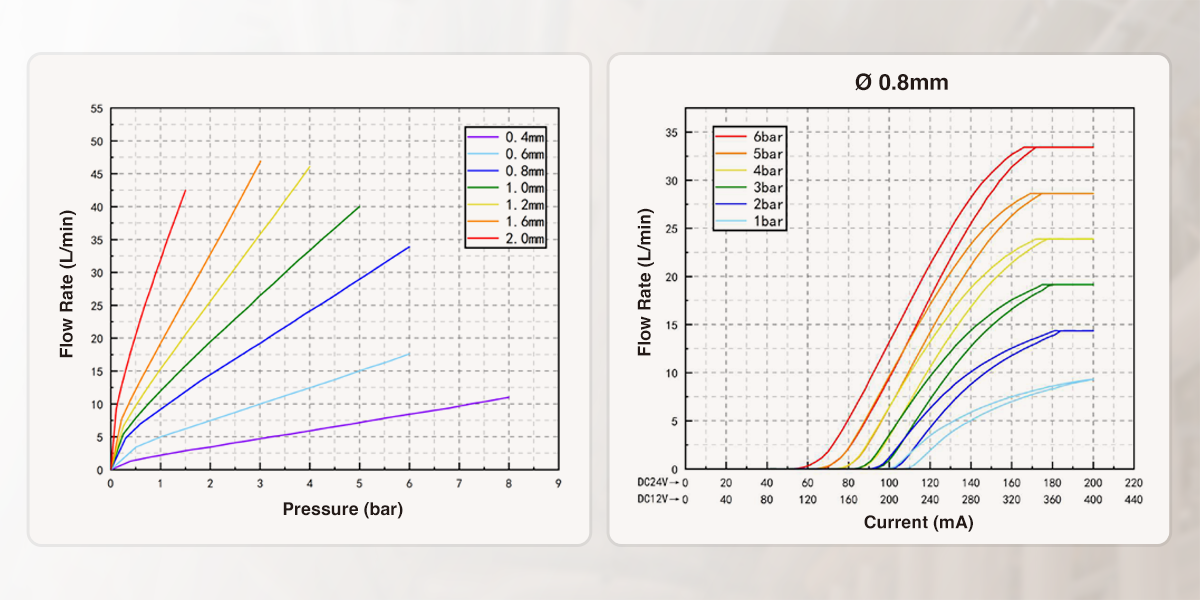

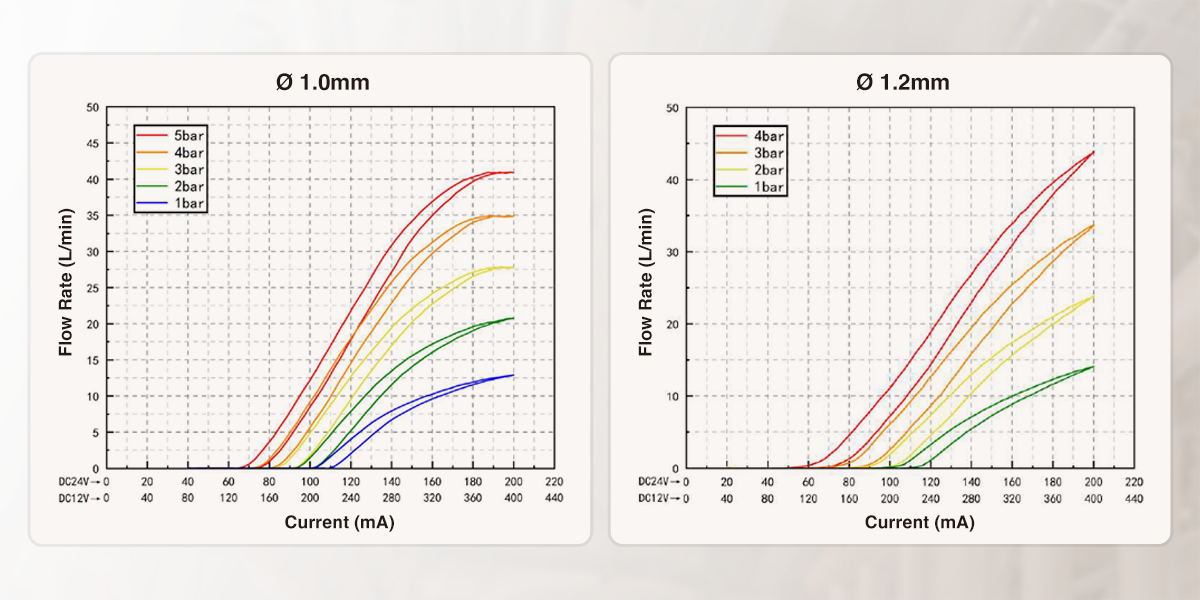

| رمز المنتج | فتحة التدفق | أقصى فرق في الضغط | أقصى معدل تدفق |

| JFHSV05010 | 0.8 مم | 6 بار | 36 لتر/دقيقة |

| JFHSV05011 | 1 مم | 6 بار | 51 لتر/دقيقة |

| JFHSV05012 | 1.2 مم | 4 بار | 44 لتر/دقيقة |

جميع الأنواع الثلاثة المذكورة في هذه القائمة مزودة بفتحة قياسها 1/8 بوصة. يُرجى اختيار فتحة التدفق المطلوبة عند إتمام عملية الشراء. يختلف أقصى فرق ضغط ومعدل تدفق حسب فتحة التدفق.

التعليمات

المشكلة الأولى: ما الذي يجب ملاحظته قبل الشراء؟

يرجى مراجعة مواصفات المنتج في هذه الصفحة (مثل مخطط تدفق الضغط ومخطط تدفق التيار) للتأكد من ملاءمتها لاحتياجاتك قبل الشراء. لأي استفسارات أو طلبات إضافية، يرجى التواصل مع فريق خدمة العملاء.

المسألة الثانية: ما الفرق بين صمام الملف اللولبي النسبي وصمام الملف اللولبي التقليدي؟

يتم التحكم في الصمام النسبي بواسطة تيار التشغيل الخاص بمغناطيسه الكهربائي النسبي. يحدد هذا التيار القوة الكهرومغناطيسية، التي بدورها تنظم موضع البكرة وفتح منفذ الصمام لتحقيق تحكم نسبي في التدفق. يقوم جهاز التحكم بتحويل الأوامر العليا إلى تيار تشغيل ثابت.

| يكتب | وظيفة | أساليب المكافحة | ||||

| صمام الملف اللولبي | يحتوي فقط على حالتين (مفتوح/مغلق)، ويظهر خارجياً على أنه قيد التشغيل وإيقاف التشغيل. | يتم تفعيله عند تشغيله؛ ويتوقف عند انقطاع التيار الكهربائي. | ||||

| صمام تناسبي | يمكن ضبط الفتح بشكل مستمر ومتناسب، والتحكم في ضغط وتدفق السوائل. | يتحكم في فتح الصمام النسبي عبر تيار قابل للتعديل باستمرار. | ||||

المسألة 3: ما هو التوصيل الكهربائي لهذا النموذج من صمام الملف اللولبي النسبي؟

يتميز جسم الصمام بواجهة كهربائية من نوع الشفرة 6.3 × 0.8 مم، كما أنه مزود بصندوق توصيل لتلبية متطلبات الأسلاك والتركيب المختلفة.

المشكلة الرابعة: كيف نستخدم صمام الملف اللولبي النسبي الخاص بنا؟

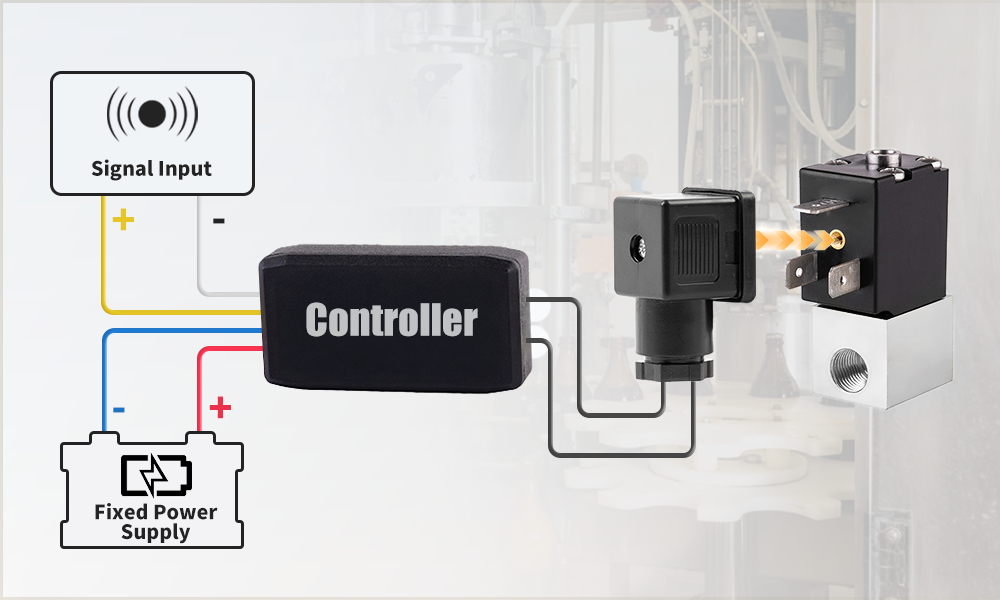

تُتحكم صماماتنا اللولبية التناسبية مباشرةً عبر إشارات تعديل عرض النبضة (PWM). ولأن المعدات الصناعية التقليدية عادةً ما توفر جهدًا ثابتًا فقط (مثل 24 فولت تيار مستمر) ولا تستطيع إخراج إشارات النبض القابلة للتعديل المطلوبة للصمام مباشرةً، فإن الأمر يتطلب وحدة تحكم تناسبية أو دائرة قيادة مخصصة للتحويل. ولتسهيل تكامل النظام، نوفر وحدات تحكم متوافقة كخيار إضافي، وتتمثل وظيفتها الأساسية في تحويل إشارة خرج النظام إلى تيار قيادة مُتحكم به يتم توليده بواسطة نبضات PWM.

ننصح بشدة باستشارة فريقنا الفني قبل الشراء لضمان التوافق التام. بناءً على متطلباتك الخاصة، يمكنك اختيار طراز وحدة تحكم متوافق مع إشارات 0-5 فولت، أو 0-10 فولت، أو 0-20 مللي أمبير، أو 4-20 مللي أمبير. إذا كنت تخطط لاستخدام وحدة التحكم الخاصة بنا مع صمام من علامة تجارية أخرى، أو استخدام وحدة تحكم من طرف ثالث مع صمامنا، فيُرجى الانتباه جيدًا للمعايير الأساسية مثل مقاومة الملف، والتيار المقنن، وتردد تعديل عرض النبضة (PWM). يمكنك إرسال اسم العلامة التجارية للصمام، وطرازه، ومتطلباتك الكهربائية المحددة إلى خدمة العملاء لدينا للتحقق من التوافق بشكل احترافي وتقديم إرشادات حول الاختيار.

كيفية استخدام وحدة التحكم من ماركة US Solid

الرسم التخطيطي هو رسم توضيحي أساسي لاستخدام وحدة التحكم المتوفرة للشراء منا.

- يتم توصيل سلكين أسودين بالصمام (يتم توصيل الأسلاك بصندوق التوصيل، والذي يتم توصيله بدوره بالصمام).

- يتم توصيل السلك الأحمر (مصدر الطاقة الموجب) والسلك الأزرق (مصدر الطاقة السالب) بمصدر طاقة ثابت.

- تُستخدم الأسلاك البيضاء (إشارة موجبة) والصفراء (إشارة سالبة) لتوصيل إشارة الإدخال.

- للحصول على معلومات حول اختيار وحدة التحكم، يُنصح باستشارة خدمة العملاء قبل الشراء.

المسألة الخامسة: ما هي الوسائط التي يناسبها الصمام؟

يُوصى باستخدامه مع الغازات والسوائل المحايدة. بالإضافة إلى ذلك، تتيح مادة منع التسرب المصنوعة من الفيتون التوافق مع المواد ذات التآكل الطفيف. إذا كنت ترغب في التأكد من ملاءمته لوسائطك المحددة، يمكنك إرسال معلومات مفصلة إلى خدمة العملاء لدينا.