Introduction

A solenoid valve provides reliable on/off control of fluids or gases in automated systems. Its compact electromechanical design ensures fast response and low power consumption.

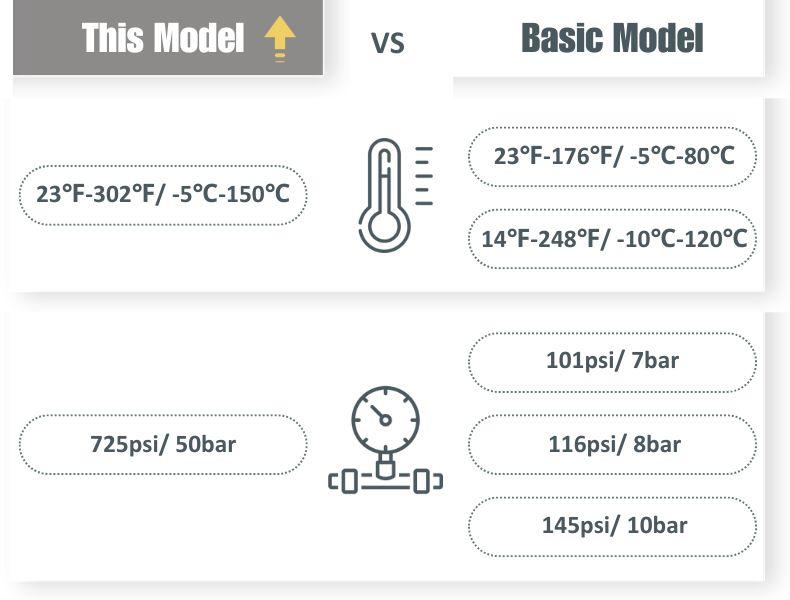

For demanding applications, upgrade to our heavy-duty solenoid valve—engineered to withstand 50 bar pressure (significantly higher than standard valves) and 300°F (150°C) temperatures where basic models fail. Featuring a solid brass body and PTFE seals, it delivers robust performance with liquids, gases, oils, or compressed air — suitable for HVAC, industrial, commercial, or household applications, as well as high-pressure systems, safety valves, and compressor valves. The integrated junction box protects wiring in harsh environments.

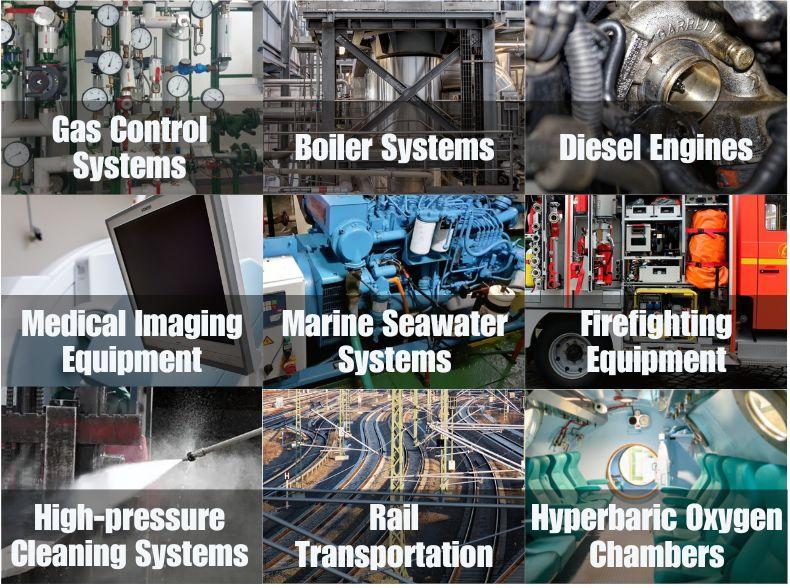

Applications

Features

- PTFE Seal: Superior to NBR and Viton in sealing, temperature, and pressure resistance.

- Normally Closed: Closed when unpowered, opens when energized.

- High-Pressure Performance: Engineered to withstand 50 bar (725 psi) — multiple times stronger than standard solenoid valves. Ideal for hydraulic systems, industrial gas control, and heavy-duty compressors where pressure surges occur.

- High Temperature Resistance: Up to 300°F for flawless operation in any environment.

- Super Responsive: Using electromagnetic force, this valve has a very fast response, of only a couple of milliseconds.

- NPT Threading (1"): Standard tapered threading for U.S. piping, ensuring a secure seal with teflon tape.

- Valve Body Material: Constructed from robust brass. Not suitable for drinking water applications.

- Junction box: Provides secure wiring protection for harsh environments (dust, moisture, vibration).

User Manual

To learn how to use this product, please refer to the user manual.

Technical Data

| Model | USS-HSV03 | Port Size | 1" | ||

| Thread Type | NPT | Body Material | Brass | ||

| Operation Type | Pilot Operated | Wiring Type | Junction Box | ||

| Operation Mode | Normally Closed | Flow Aperture | 25 mm | ||

| Flow value | 11.67 Cv | Gasket/Diaphragm/Seal | PTFE | ||

| Operating Time | ≤1s | Rated Voltage | DC 12V | ||

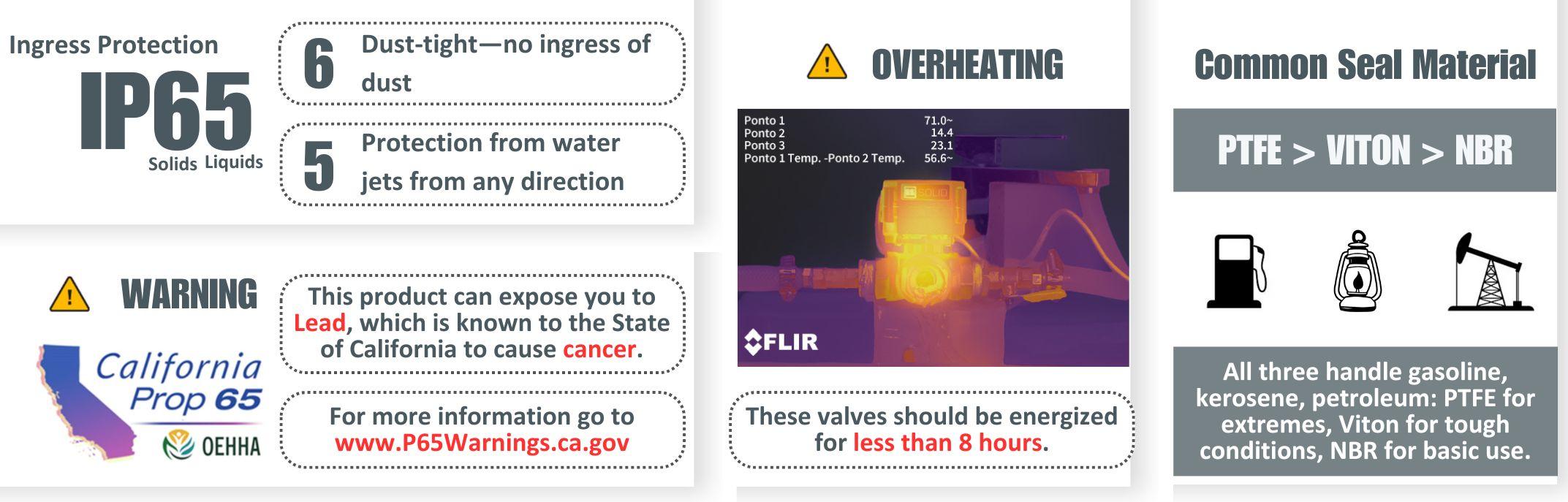

| IP Rating | IP65 | Power | 16W | ||

| Operating Temperature | 23℉-302℉(-5℃-150℃) | Suitable Liquid Viscosity | 20 cst Below | ||

| Operating Pressure | Air/Water/Oil: 1-50Bar(14.5-725 PSI) | Suitable Media | Air, water, diesel oil, kerosene, etc. | ||

| Net Weight | 3.86 lbs | Product Dimensions | 5.16"x4.03"x2.53" | ||

*To view the full table on mobile, please swipe left or right on the screen.

Operating Principle

Pilot-operated solenoid valves

This solenoid valves work by first opening a small pilot valve when energized, which then uses system pressure to operate the main valve. When de-energized, the pilot closes and the main valve resets. This design enables efficient control of high-pressure and large-flow systems with minimal power consumption, though it requires minimum operating pressure to function properly.

Precautions

- It is recommended to filter the fluid before use to prevent impurities from blocking the valve, which could lead to incomplete closure.

- Flow Direction: During installation, ensure the arrow on the valve body aligns with the medium's flow direction. If reverse pressure is possible, install a check valve to prevent backflow.

- To ensure optimal performance and extend the solenoid valve's lifespan, install it horizontally with the coil facing vertically upward. Avoid vertical or backward coil orientation.

- The solenoid valve generates heat during operation. Avoid direct contact with your hands.

- Solenoid valves that have been out of service for an extended period should be cleaned to remove any accumulated impurities or condensation before use.

- To ensure a secure seal, always use Teflon tape when connecting NPT threads.

FAQ

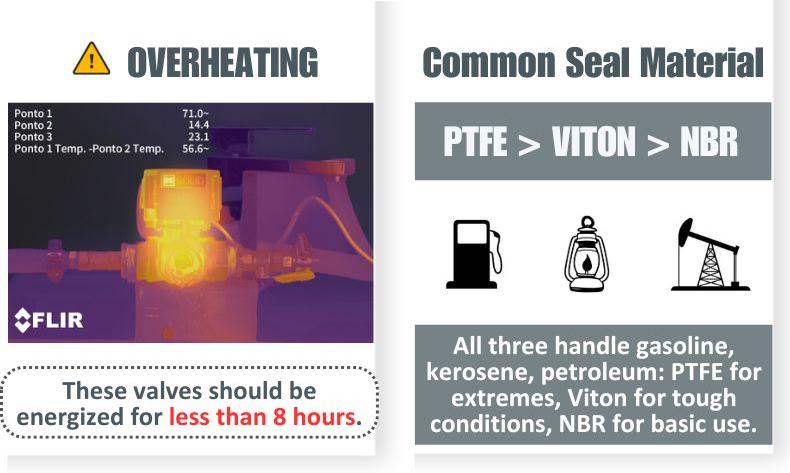

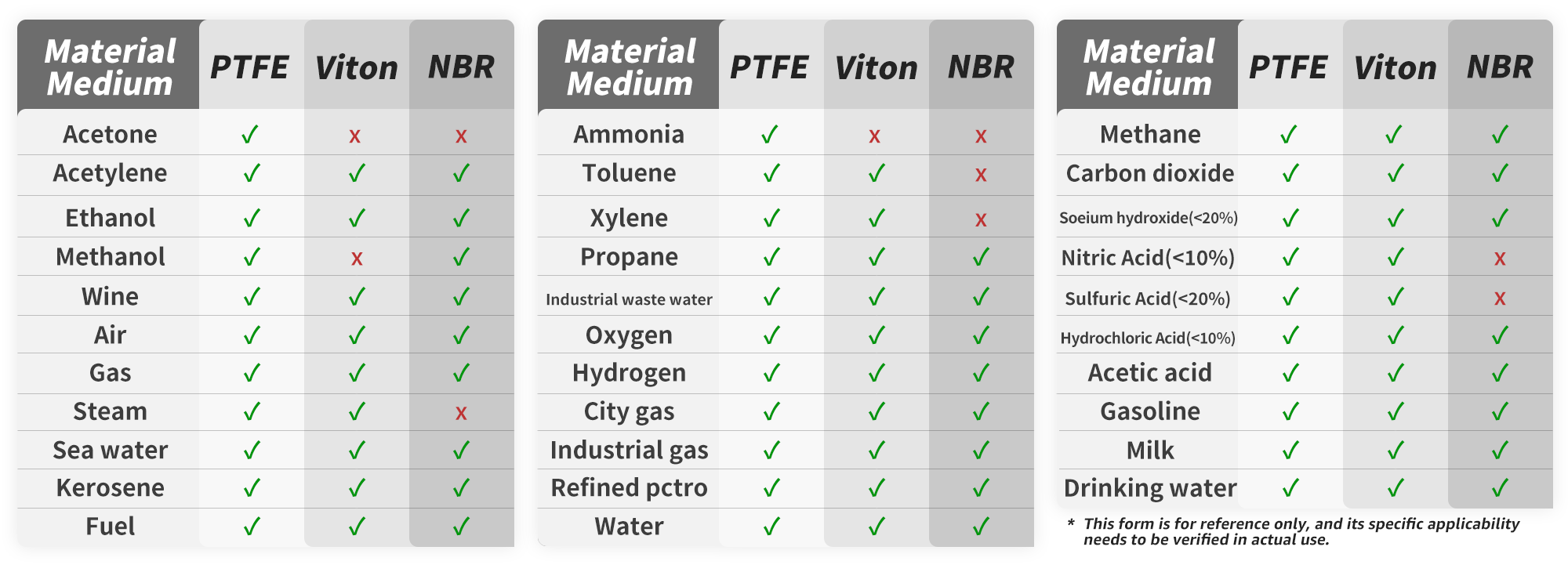

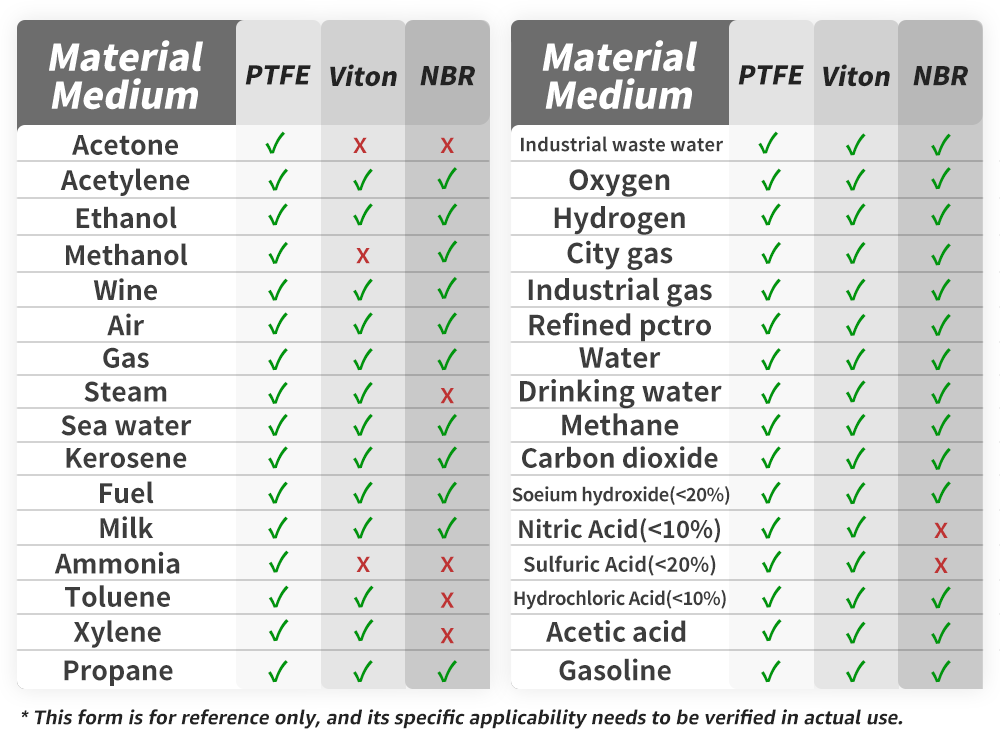

Problem 1: Which material (PTFE, Viton, or NBR) is best for gasoline, kerosene, and petroleum products?

PTFE (best resistance) > Viton (good) > NBR (basic) — all work, but PTFE handles extremes best.

Problem 2: Can these solenoid valves be used continuously for extended periods?

These valves should be energized for less than 8 hours. While most do not exceed 18W of power, the coils are in a contained area and can burn out if energized for too long. We recommend using a computer fan to keep the coil cool if continuous operation is necessary.

Problem 3: How long should you wait between two consecutive five-hour uses of our solenoid valve?

It is recommended to allow about 20 minutes of cooling time between two consecutive 5-hour operating sessions. The exact cooling time may vary depending on ambient temperature and operating conditions.

Problem 4: How long does a solenoid valve last?

With a lifespan of over a million cycles when maintained properly, the actual longevity may vary depending on factors such as operating conditions, fluid type, pressure, temperature, and maintenance practices.

Problem 5: Can this be used for Drinking Water?

NO. This solenoid valve is made of brass, which contains lead, should not be used for drinking water.

Problem 6: Can it be used outdoors?

While the solenoid valves have an IP65 rating, making them resistant to water spray, it is recommended to enclose the valve in a protective housing if permanently installed outdoors to ensure long-term durability.

Problem 7: What does the arrow on the valve body indicate?

The arrow on the valve indicates the flow direction. Most U.S. Solid valves are unidirectional, meaning they are designed to operate correctly only when fluid flows in the direction of the arrow. If installed in the opposite direction, the valve may not function properly (e.g., a Normally Closed valve may fail to close).

Problem 8: What is the difference between N.C. (Normally Closed) and N.O. (Normally Open)?

- Normally Closed (NC): Valve remains closed when power is off, opening only when energized. Ideal for fail-safe closed applications.

- Normally Open (NO): Valve remains open when power is off, closing only when energized. Ideal for fail-safe open applications.

*Important: Check marks (√) denote conditional suitability only; crosses (×) indicate complete incompatibility.