INTRODUCTION

The U.S. Solid Handheld Winding Machine is dual - purpose, for both electric and manual coil winding. In manual mode, it's operated via a hand crank on the right. Electric winding enables automatic, evenly - layered coils with proper tension, though a motor (not included) is needed.It has a 1:8 transmission speed and an easy - to - read counter that counts up to 9999 rings for coil quantity determination.Suitable from home electronics projects to commercial coil - packaged product manufacturing, it also helps salespeople in retail settings to efficiently assess sold product volume and inventory.

FEATURES

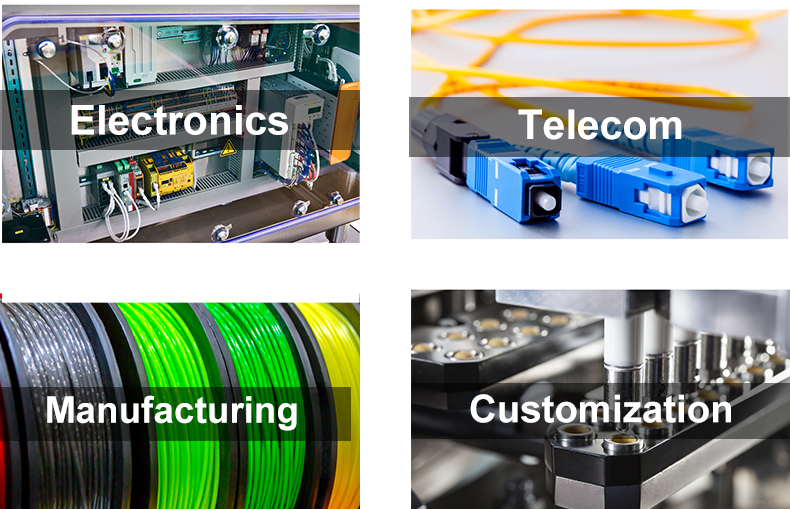

APPLICATIONS

SPECIFICATIONS

| Model | USS-HWM00001 | Brand | U.S. Solid |

|---|---|---|---|

| Diameter of the Coils | 10 - 150mm | Maximum Coil Width | 100mm |

| Wire gauge limits | ≥18 AWG (diameter<1mm) | Count Range | 0-9999 rings |

WARNING

1.Fix the NZ-1 to a vibration-resistant workbench using all three mounting holes. Inadequate fastening may generate operational vibrations, compromising coil uniformity critical for precision components like magnetic heads. Verify bench stability before production cycles.

2.Reset the winding counter to "00000" twice during machine initialization. Resetting during operation is strictly prohibited to prevent gear disengagement and miscounts. Implement pre-run verification checks to ensure accurate winding cycles and material efficiency.

3.Apply ISO VG32-grade oil to spindle ports every 8 operational hours. Maintain lubrication logs to prevent bearing wear and torque inconsistencies. Unlubricated operation voids warranty coverage and risks premature drive system failure.

4.Maximum permissible winding dimensions: Ø150mm (diameter) × 100mm (length). Exceeding these parameters overloads spindle bearings and deforms tension arms. Use template gauges for batch production verification to maintain winding geometry specifications.

5.Continuous operator presence is mandatory during winding cycles. Monitor for irregular acoustic signatures (>75dB) or frame oscillations (>0.5mm amplitude). Immediate E-stop activation is required for any deviation, followed by maintenance inspection before resumption.

Download user manual here