Introduction

The U.S. Solid Electric Strapping Machine uses the principle of friction heat fusion to weld two straps together. Designed for high-efficiency and secure packaging, this machine is ideal for industries such as logistics, manufacturing, and e-commerce. With its powerful performance and user-friendly operation, it meets the growing market demand for improved packaging efficiency and reliability in both small and large-scale operations.

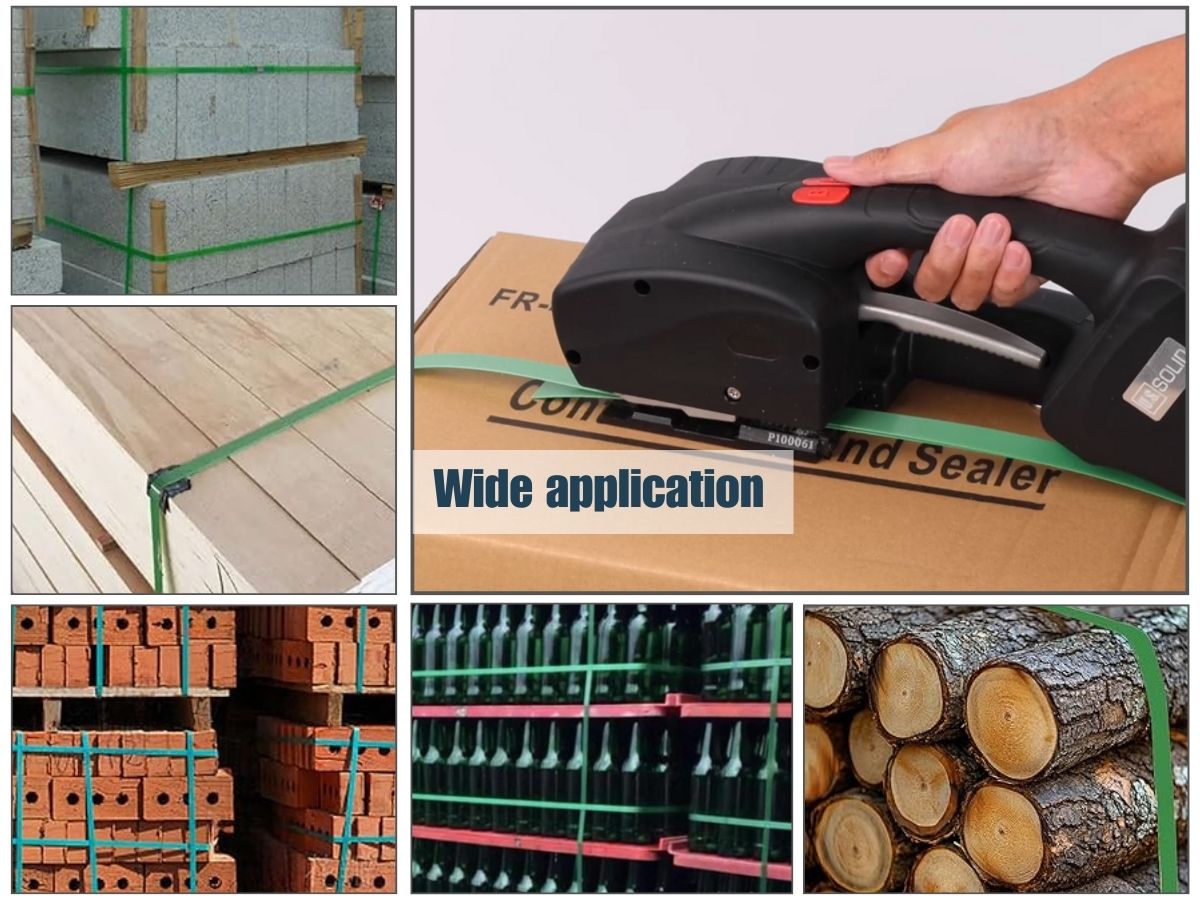

Easily cope with various packaging scenarios. For example paper industry, aluminum industry, steel industry, wood, wooden box packaging, chemical fiber, cotton spinning, chemical industry, metal products, and other industries.

Applications

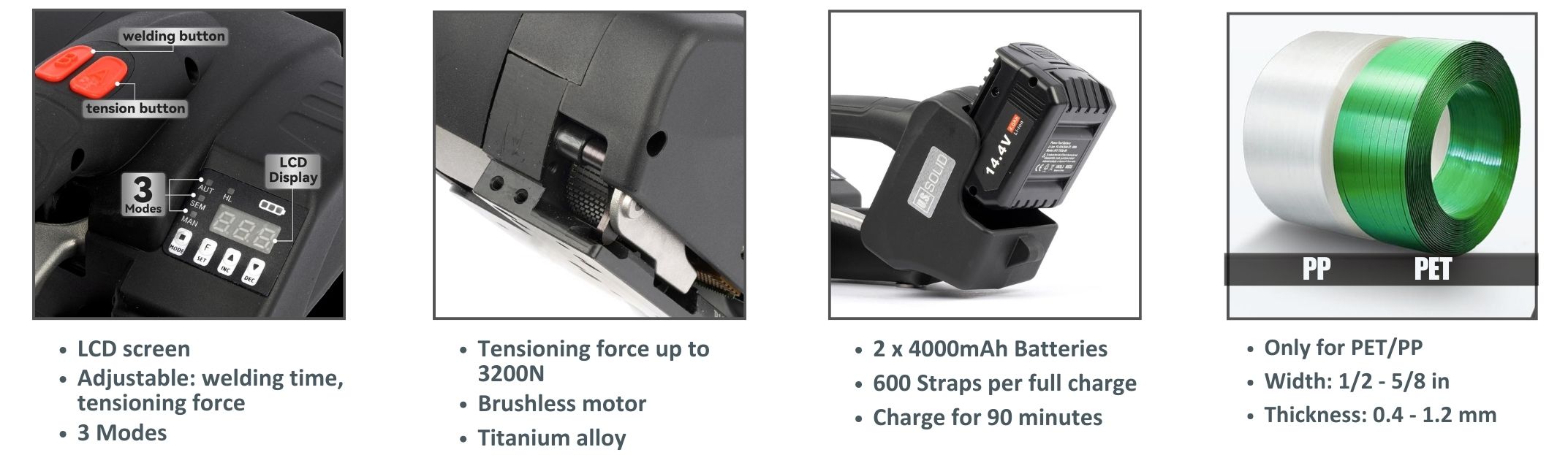

Features

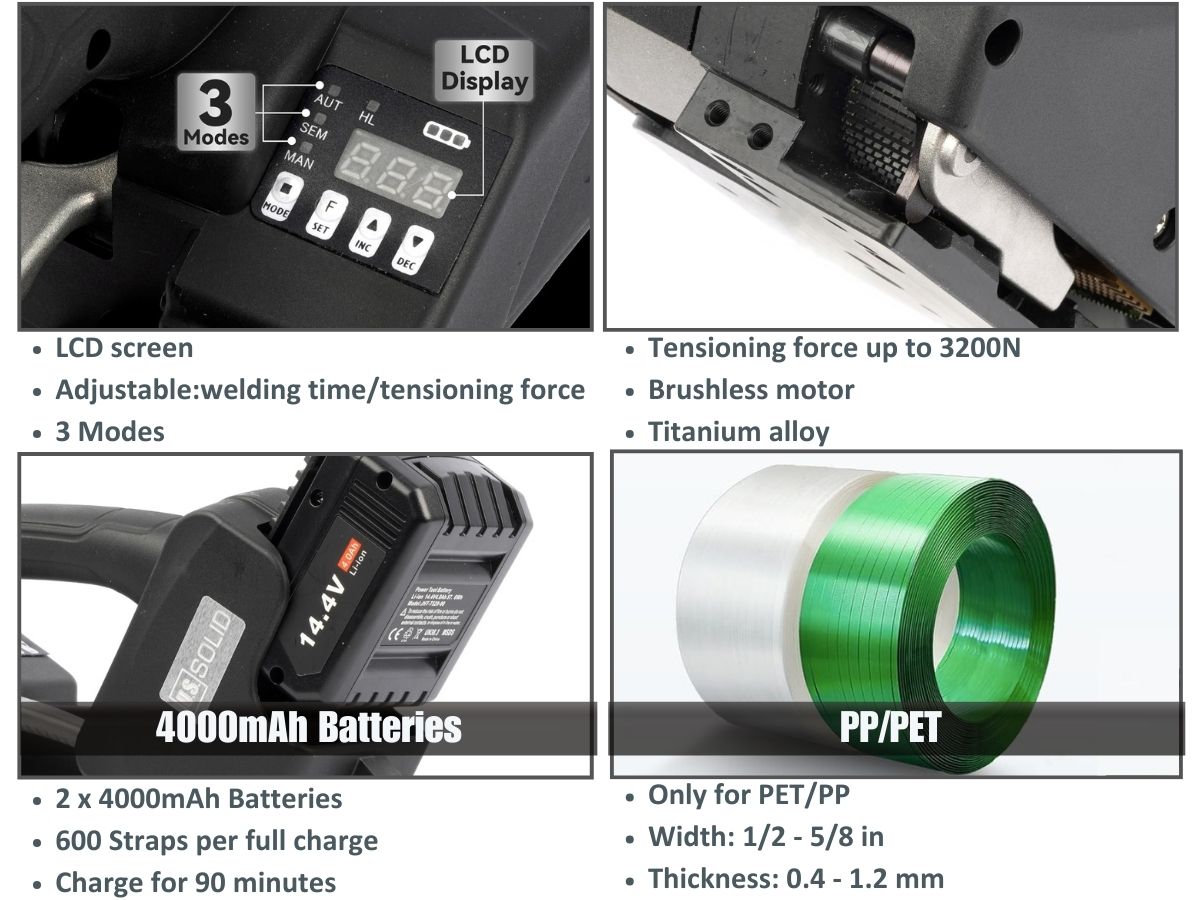

- Three Modes:Fully automatic, semi-automatic, and manual modes for different needs. Choose the best mode based on your situation. The built-in high-tech chip enhances machine quality and efficiency.

- 2 x 4000mAh Batteries:Two rechargeable lithium batteries, capable of completing 600 strappings per charge. Each charges for only 90 minutes.

- LCD Screen:Our machine equips with an LCD screen, instead of adjusting the welding time and tightening force through knobs blindly. You could accurately adjust the parameter according to the packing situation, bring your packaging process to the perfect state.

- For PP & PET Strapping:Compatible with 1/2-5/8 in wide, 0.4 to 1.2 mm thick PET (Polyester) and PP (Polypropylene) strapping by replacing the spring and accessories.

- No Need For Buckles:Friction heat fusion welds the straps with 75% of their maximum load-bearing strength, ensuring they won’t break easily, eliminating the need for extra buckles.

- Adjustable:Welding time and tightening force can be easily adjusted via buttons, with real-time digital display on the LCD screen.

- Packing List:In addition to the main machine, two batteries, the battery charger and the user manual, an additional tool kit will be provided.

More Details

Technical Data

| Model | USS-ESM00030 | Suitable Strapping Thickness | 0.4-1.2mm |

| Operation Method | Automatic, Semi-automatic and Manual | Packing Efficiency | 600 pcs(Approx. per Charge) |

| Display | LCD screen | Charging Time | 90min |

| Voltage | 14.4V | Adhesive Strength | 75% |

| Battery Capacity | 4.0Ah | Input | AC 100-240V;50/60Hz;1.5A |

| Battery Quantity | 2 | Ambient Air Temperature | 41℉ to 113℉ (5℃ to 45℃) |

| Battery Type | Lithium battery | Optimum Working Temperature | 59℉ to 68℉ (15℃ to 20℃) |

| Suitable Strapping | PP, PET | Product Dimensions | 14.17x5.71x4.72 in(36x14.5x12 cm) |

| Maximum Tensioning Force | 3200N | Net Weight | 4.35kg/9.59lb |

| Suitable Strapping Width | 1/2-5/8in | Battery Net Weight | 0.6kg/1.31lb |

| Tensioning Force | Adjustable | Welding Time | Adjustable |

*The values such as Packing Efficiency, Charging Time, and Adhesive Strength are for reference only and may vary in actual use due to various factors, such as the quality of the straps.

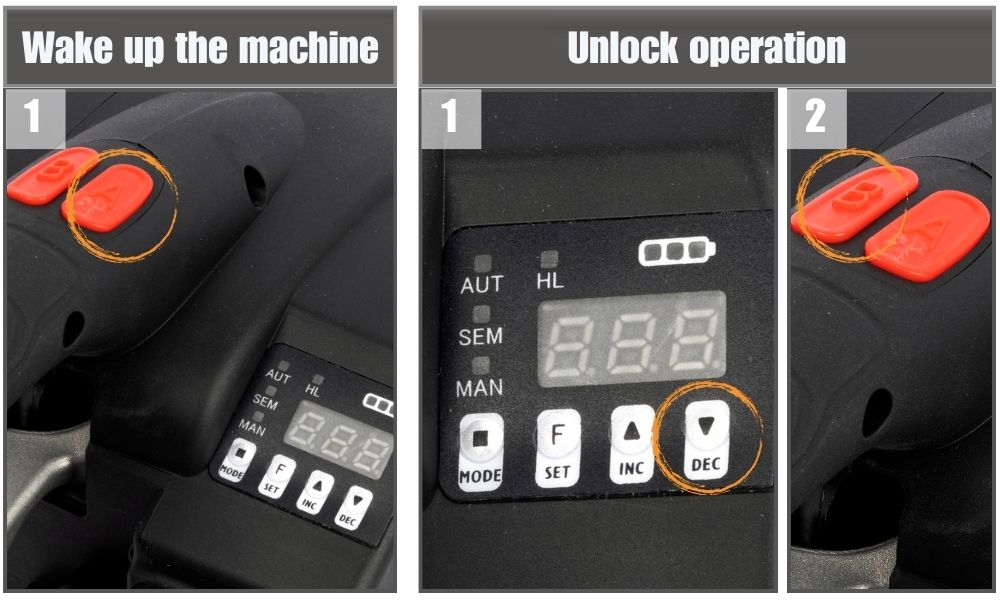

Locking and Unlocking

Wake up the machine

After 120 seconds of inactivity, the machine enters sleep mode.

To wake it up, gently press the tensioning button (button on the right handle) to resume operation.

Unlock operation

The machine will auto-lock after 30 seconds of inactivity.

To unlock, press and hold the "DEC" button for 2 seconds until you hear a prompt, then press the welding button (button on the left handle) to resume operation. Do not press the welding button fully, as it will trigger a welding operation.

Precautions

1.Ensure the strap matches the spring installed in the machine

This electric strapping machine comes with a default spring for fusing PET straps (recommended U.S. SOLID PET strapping). For PP straps, please replace the spring with the one provided. For installation guidance, refer to the video or contact customer service.

2.Optimal welding time

Adjust welding time using the buttons to find the optimal setting before first use. Many factors, such as temperature and strap thickness, can affect the welding time.

3.Clean strap residue on the cutting gear

Avoid damaging the machine and yourself.

4.Strapping jams (LED in red)

If straps get jammed, switch off the power, cut the straps, remove the screws on the left and right panel covers, and clear the straps. Then, check for issues like dislodged lines on the travel switch and replace the micro switch if necessary.

5.Motor not rotating

Press the welding and tensioning buttons to check the motor and micro switch. Replace them if needed.

All Options

| Model | USS-ESM29 | USS-ESM01 | USS-ESM24 | USS-ESM30 | USS-ESM23 | USS-ESM12 | USS-ESM26 | USS-ESM16 | USS-ESM25 | USS-ESM31 |

| Operation Method | Auto | Auto, Manual | Auto, Semi-Auto, Manual | Auto | Semi-Auto | |||||

| Display | × | LCD screen | LCD screen | LCD screen | LED touch-screen | LCD screen | LCD screen | × | × | LCD screen |

| Voltage | 11.1V | 14.4V | 14.4V | 14.4V | 18V | 18V | 14.8V | 14.4V | 14.4V | 18V |

| Battery Capacity | 4.0Ah | 4.0Ah | 6.0Ah | 4.0Ah | 5.0Ah | 5.0Ah | 4.0Ah | 3.0Ah | 3.0Ah | 2.0Ah |

| Battery Quantity | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| Strapping Type | PP, PET | PP, PET | PP, PET | PP, PET | PP, PET | PP, PET | PP, PET | PP, PET | PP, PET | PP, PET |

| Max Tensioning Force | 2800N | 3200N | 3200N | 3200N | 3500N | 4500N | 5500N | 2100N | 3200N | 2800N |

| Strapping Width | 1/2-5/8in | 1/2-5/8in | 1/2-5/8in | 1/2-5/8in | 1/2-5/8in | 1/2-5/8in | 1/2-1in | 1/2-5/8in | 1/2-3/4in | 1/2-5/8in |

| Strapping Thickness | 0.4-1.2mm | 0.4-1.2mm | 0.5mm-1.2mm | 0.4-1.2mm | 0.4-1.2mm | 0.4-1.2mm | 0.4-1.2mm | 0.4-1.2mm | 0.4-1.5mm | 0.4-1.2mm |

| Packing Efficiency | 250pcs | 250-350pcs | 400pcs | 600pcs | 600pcs | 600pcs | 180pcs | 300pcs | 300pcs | 300-400pcs |

| Charging Time | 90min | 90min | 90min | 90min | 90min | 90min | 90min | 90min | 90min | 90min |