INTRODUCTION

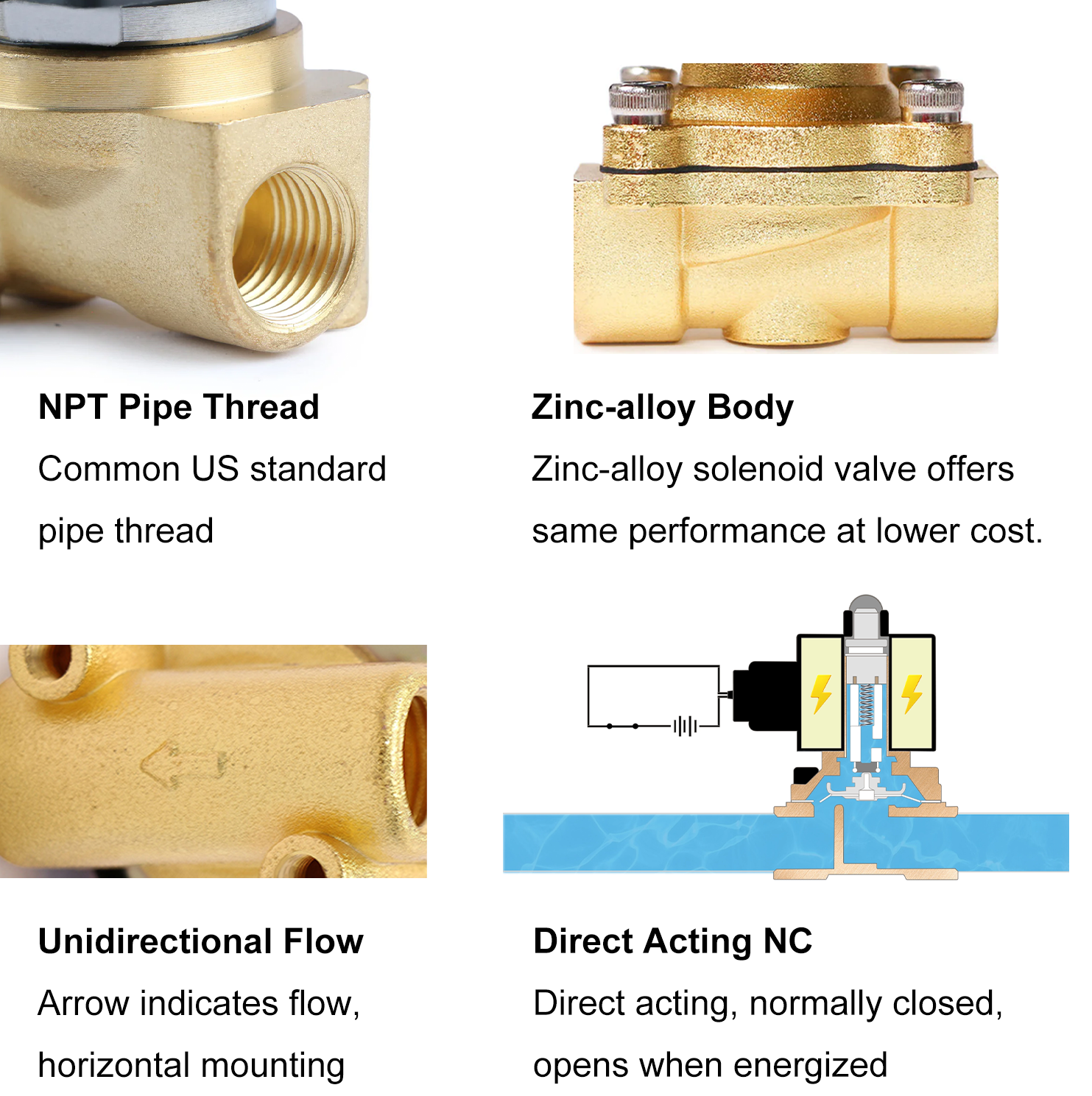

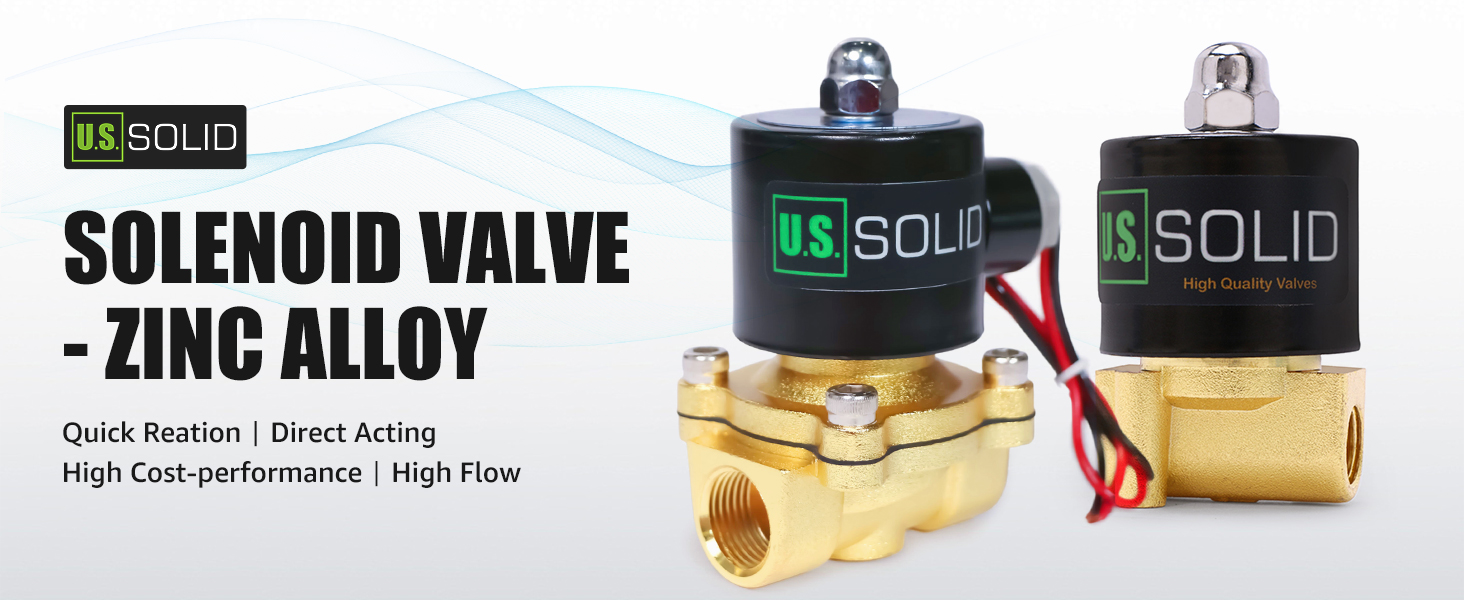

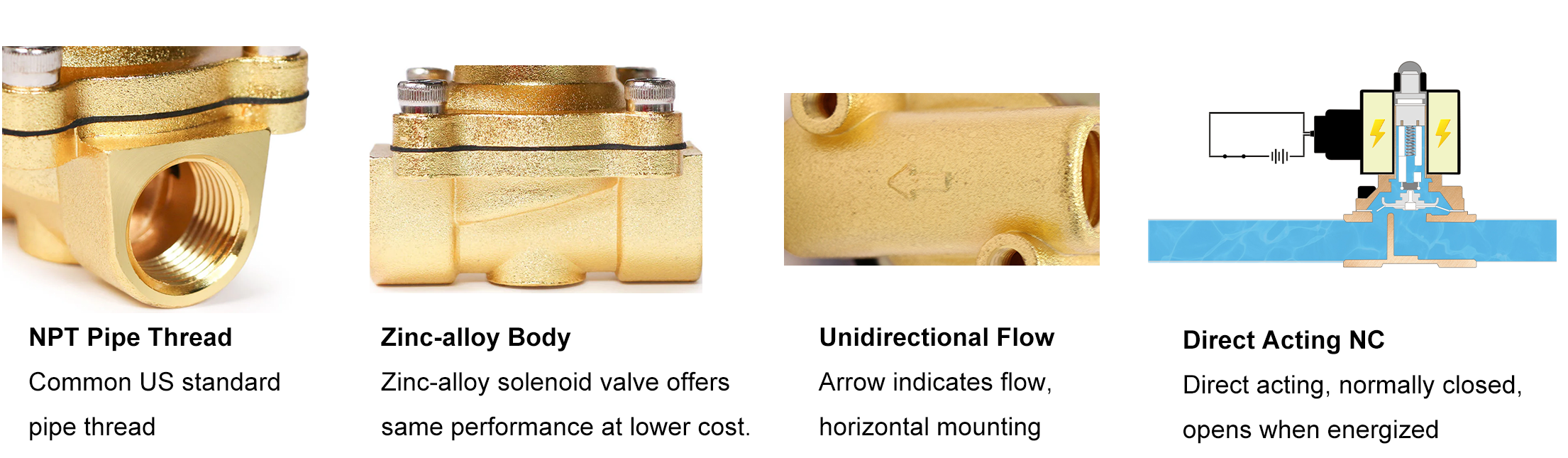

The U.S. Solid USS-ZSV Series Zinc-alloy Solenoid Valves are engineered with both performance and cost-effectiveness in mind. These valves utilize a zinc alloy valve body, a material selected for its ability to withstand significant pressure while offering a more economical solution than brass or stainless steel. This series is designed to be a reliable and affordable option for various applications, making it a valuable addition to your toolkit.

FEATURES

APPLICATIONS

|

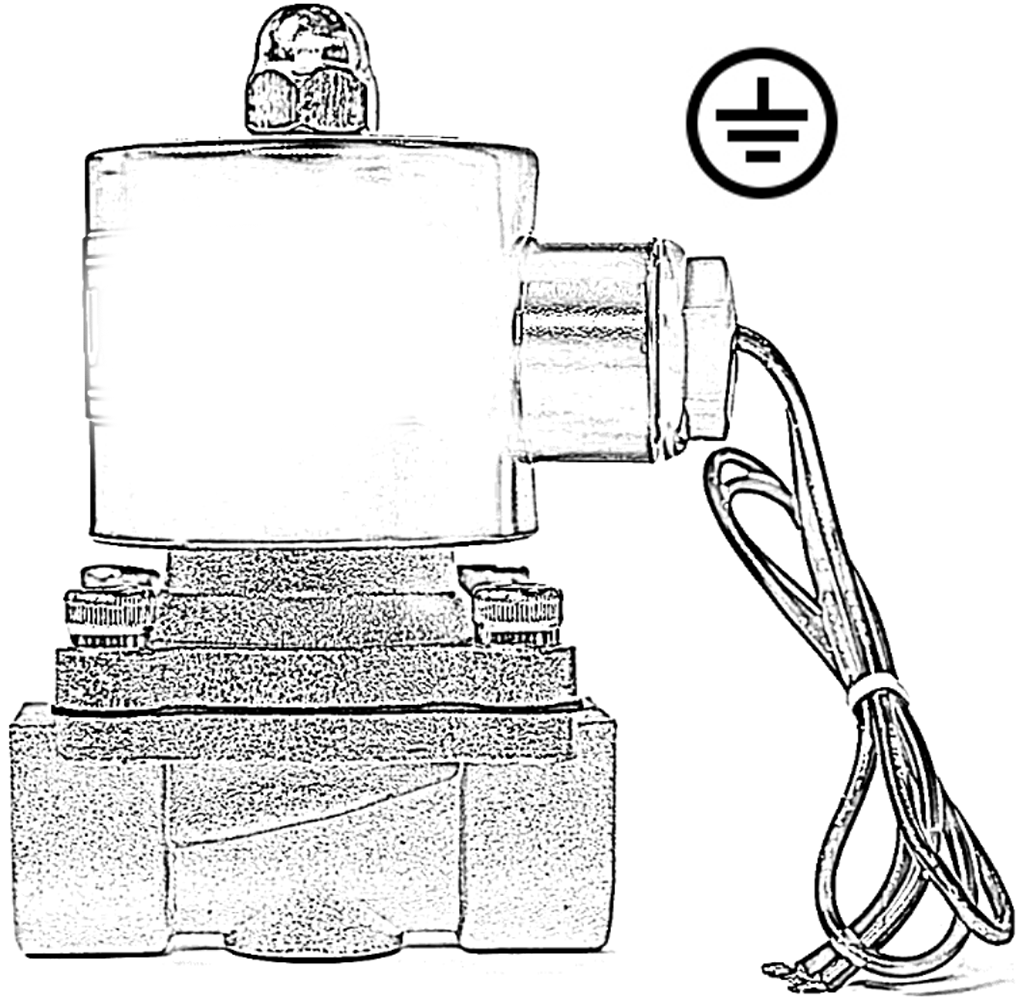

POLARITY When dealing with valves equipped with two wires, an important characteristic to note is their polarity - insensitive design. This means that the valve will actuate correctly regardless of which terminal each wire is connected to. Whether a wire is attached to the positive (+) or negative (-) terminal makes no difference in the valve’s operation. However, it’s essential to be aware that some valve units incorporate an additional ground wire.To determine if your valve has a ground wire, you’ll need to open up the connector.For valves with a ground wire, proper grounding is crucial. |

SPECIFICATIONS

| Model | USS-ZSV00014 | Brand | U.S. Solid |

|---|---|---|---|

| Size | 3/4" | Flow Aperture | 20 mm |

| Valve Material | Zinc Alloy | Gasket / Diaphragm / Seal | NBR |

| Rated Voltage | AC 24V | Operational pressure range | Air/Water: 0-8 Bar (0 to 116 PSI); Oil: 0-5 Bar(0 to 72 PSI) |

| Power Rating | 22 VA | Operation Type | Direct Lift Valve |

| Suitable Media | Water, oil, Diesel fuel, kerosene etc. | Flow Value | 7.6 Cv |

| Temperature, Minimum | 14 degrees Fahrenheit (-10 degrees Celsius) | Temperature Maximum | 176 degrees Fahrenheit (80 degrees Celsius) |

| Maximum Operational temperature | NPT | Operating State | Normally Closed |

|

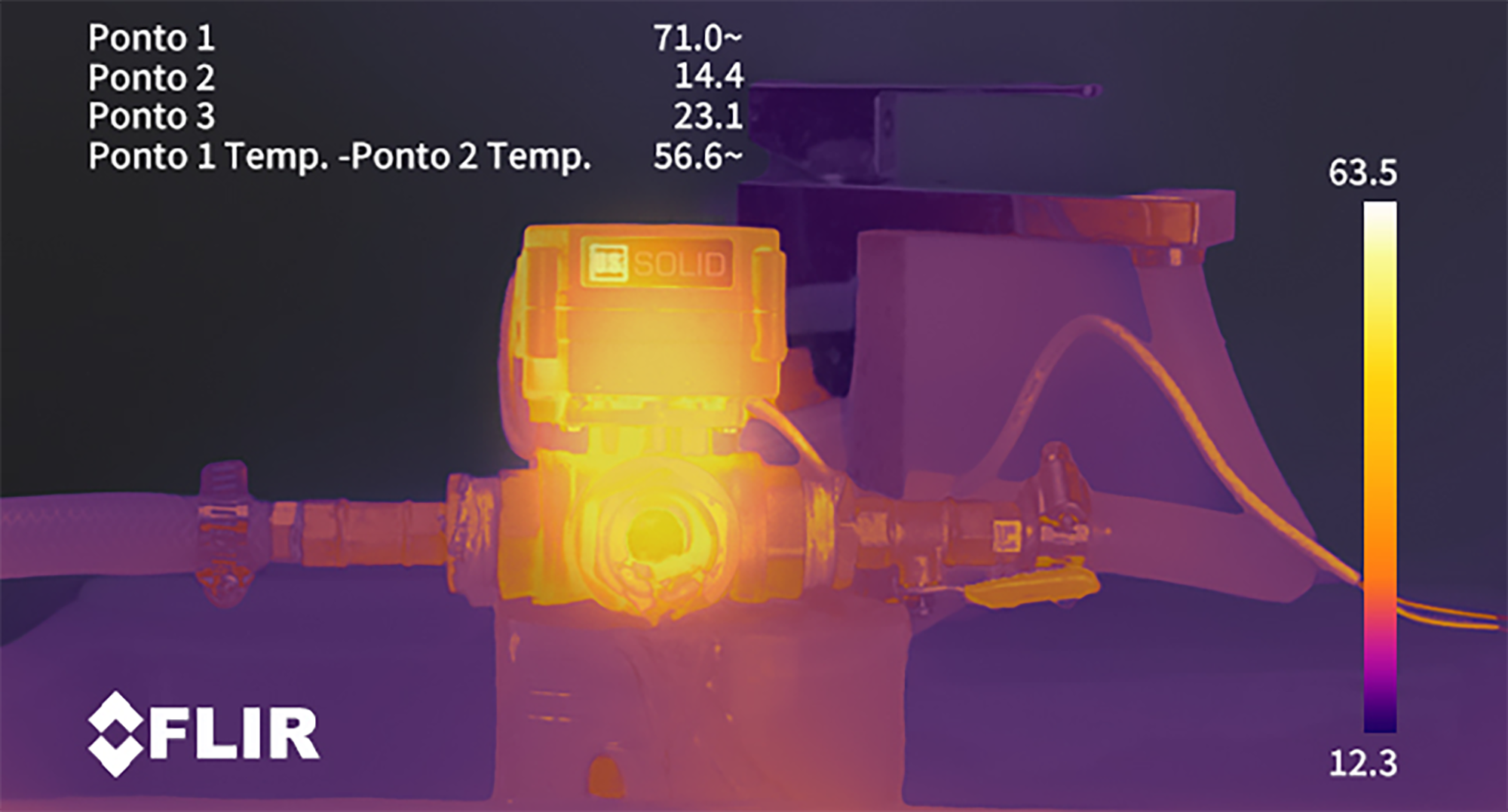

OVER HEATING Not designed for continuous operation(not a 100% duty cycle). While energized, under normal operating conditions, solenoid valve will get HOT. The coil will reach a maximum temperature of about 176°F (80°C), which is fully complied with national standard: JB/T7352-2010. If energized continuously for more than 8 hours the coil may burn. |

|

FAQ

1. Can it be used outdoors?

Solenoid valves can withstand water spray. However, if they are to be permanently installed outdoors, it’s advisable to house them in a protective enclosure. This helps safeguard the valves and ensures their long - term durability.

2. Can these solenoid valves be used continuously for extended periods?

These valves should be energized for less than 8 hours. While most do not exceed 18W of power, the coils are in a contained area and can burn out if energized for too long. We recommend using a computer fan to keep the coil cool if continuous operation is necessary.

3.How long should you wait between two consecutive five-hour uses of our solenoid valve?

It is recommended to allow about 20 minutes of cooling time between two consecutive 5-hour operating sessions. The exact cooling time may vary depending on ambient temperature and operating conditions.

4.Can this be used for Drinking Water?

Yes. This motorized ball valve is crafted from zinc alloy. Zinc alloy is free of lead, making it suitable for use in drinking water systems.

Download user manual here.