Introduction

The peristaltic pump offers precise fluid delivery by compressing flexible tubing, making it ideal for applications requiring contamination-free and accurate fluid transfer, such as in laboratories, medical devices, and pharmaceutical industries.

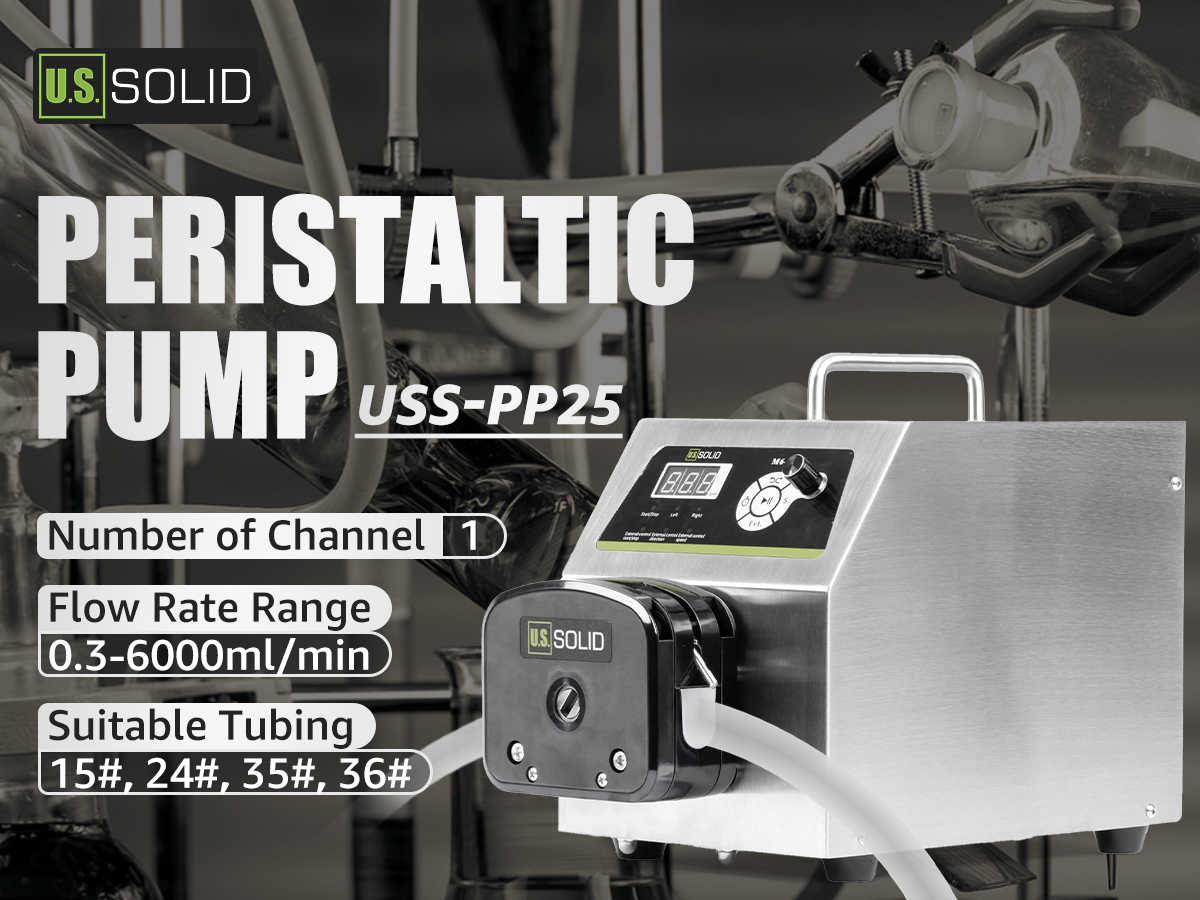

The U.S. Solid M6-6L peristaltic pump is compatible with the DZ25-6L pump head and various tubing sizes, including 15#, 24#, 35#, and 36#.

It offers a speed range from 0.1 to 600 rpm, which results in a flow rate range of 0.3 to 6000 mL/min. Powered by a reliable servo motor, the pump delivers high-output torque, along with significant suction stroke and lift capabilities. Speed adjustments can be made manually via a digital knob or automatically through the external control interface, supporting up to 7 external control modes, offering increased flexibility and ease of use.

Applications

Features

- Flow Rate Range: 0.3-6000ml/min

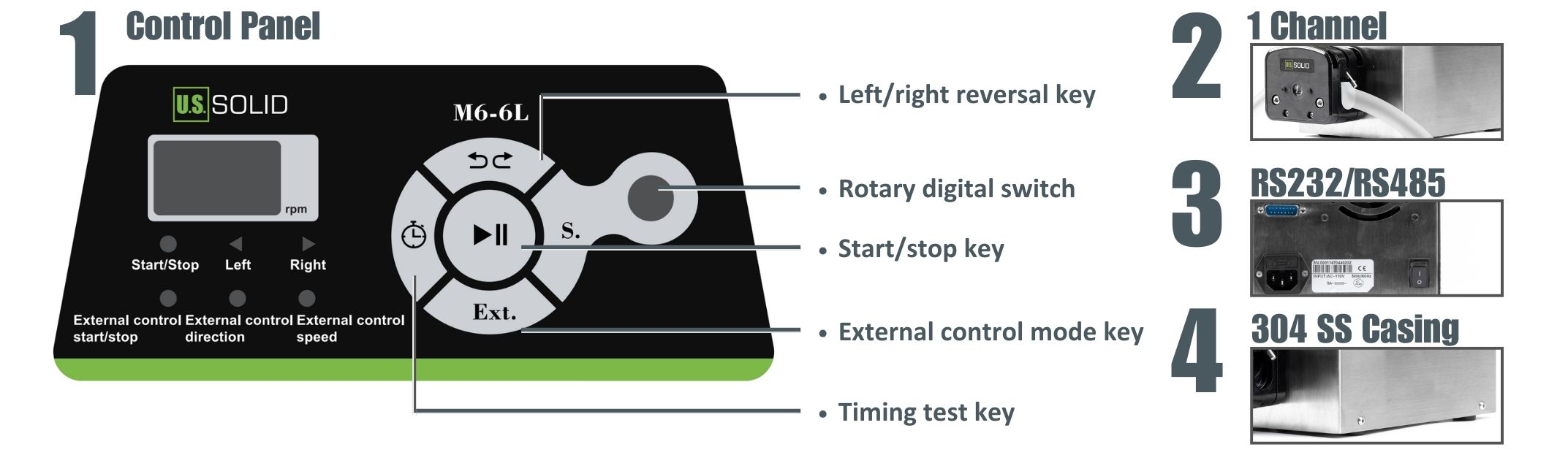

- 3-Digit LED Display: Shows motor speed in real time.

- Adjustable Speed: Manual control via digital knob or automatic control through an external interface with up to 7 modes.

- 304 Stainless Steel Housing: Prevents liquid spills from seeping into the internal components.

- Servo Motor Drive: Precise control, strong power, low vibration, low noise, and maintenance-free.

- Triple-Coated PCB: Dustproof, moisture-resistant, and anti-static.

- Communication Support: Compatible with RS-232 and RS485 protocols.

- Timer and Memory Functions

- Versatile Applications: Suitable for industrial environments, supporting high-flow and high-precision liquid transfer.

More Details

User Manual

For detailed information on installation, setup, usage, and features like External Control Instruction, please refer to the user manual and watch the tutorial video.

Other content includes MODBUS Protocol, please click to view.

Packing List

| ① | 1 x M6-6L Drive | ⑦ | 1 x English Manual of M6 Series Drive | ||||||

| ② | 2 x DZ25-6L Pump Head | ⑧ | 1 x English Manual of DZ25 Series Pump Head | ||||||

| ③ | 1 x 2-meter 15# tubing | ⑨ | 1 x Power Cable | ||||||

| ④ | 1 x 2-meter 24# tubing | ⑩ | 1 x Wrench | ||||||

| ⑤ | 1 x 2-meter 35# tubing | ⑪ | 8 x Tubing Connector | ||||||

| ⑥ | 1 x 2-meter 36# tubing | ||||||||

*To view the full table on mobile, please swipe left or right on the screen.

Precautions

1.Screen does not light up when the switch is turned on

Check if the power cable is properly and securely connected./Confirm that there is power supply./Check if the fuse is damaged.

2.Pump head does not rotate when the start button is pressed

Check if the pump head screws are tightened./Check for any foreign objects blocking the pump head rollers./Check if the roller bearings are severely corroded and unable to rotate (check after power off)./Confirm if the machine is in external control mode (refer to external control instructions).

3.No fluid transfer during operation

Check if the hose installed is compatible with the pump head./Confirm if there is enough fluid at the inlet (fluid level above the pipe inlet)./Check if there is any damage or leakage in the pipe and replace or seal it./Check if any solid material is blocking the pipe.

4.Actual fluid output does not match the preset value

Check if the hose settings for the pump head match the actual installation and usage./If using external control, confirm if the external control signal is complete or has attenuation.

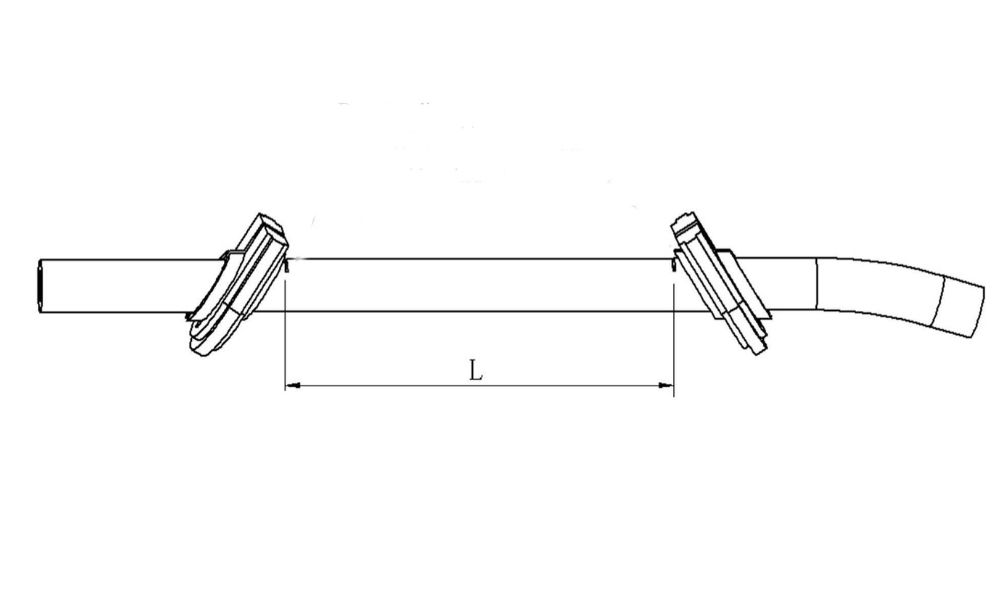

How to Install the Tubing

Clamp the tubing into the tubing clamps

- The side of the tubing clamps, which marks the size of the tubing, such as "36", needs to be faced outward.

- The distance between the two sharp corners of the tubing clamps is suggested to be set as 90-95mm.

- If you think it's too tight, it doesn't matter to expand a little bit. If you think it's too loose, it doesn't matter to narrow a little bit.

Technical Data

| Model | USS-PP24 | USS-PP93 | USS-PP25 |

| Flow Rate Range | 0.211-3600ml/min | 0.211-3600ml/min | 0.3-6000ml/min |

| Number of Channel | 1 | 2 | 1 |

| Power Consumption | <80W | <80W | <180W |

| Product Dimensions | 11.42x7.48x6.30 inches | 14.17x8.07x6.10 inches | 13.19x10.63x7.68 inches |

| Gross Weight | 14.33 lb | 16.5 lb | 22.69 lb |

| Display | 3 digital LED | ||

| Motor Type | Servo motor | ||

| Housing material | 304 Stainless steel | ||

| Tubing | 15#, 24#, 35#, 36#(2m, Silicone rubber tubing) | ||

| Control | Mechanical keypad | ||

| Speed Control | Rotary encoded knob | ||

| External Control | Passive switch signal | ||

| Speed Range | 0.1-600rpm | ||

| Speed Resolution | 0.1rpm(0-100rpm), 1rpm(100-600rpm) | ||

| External Speed Control Signal | 0-5V(standard)0-10V, 4-20mA(optional) | ||

| Timing Test Range | 0.5-999s | ||

| Condition Temperature | 0-40℃ | ||

| Communication | RS232(standard) RS485(optional), with MODBUS protocol(RTU mode) | ||

| Relative Humidity | <80% | ||

| IP Rate | IP31 | ||

| Power Supply | AC 110V/60Hz | ||

*To view the full table on mobile, please swipe left or right on the screen.

Accessories

| Replacement | Model | Thickness | Inner Diameter | Length | Pressure Rating | |

| Continuous | Maximum | |||||

| Silicone Tubing | USS-PP76-2M | 2.4mm | 4.8mm | 2m | 0.17MPa | 0.27MPa |

| USS-PP76-15M | 15m | |||||

| USS-PP77-2M | 6.4mm | 2m | ||||

| USS-PP77-15M | 15m | |||||

| USS-PP79-2M | 9.6mm | 2m | 0.14MPa | 0.24MPa | ||

| USS-PP79-15M | 15m | |||||

| Replacement | Model | Description | ||||

| Tube Clamps | USS-PP114 | For 15# tubing (thickness 2.4mm, inner diameter 4.8mm) | ||||

| USS-PP114 | For 24# tubing (thickness 2.4mm, inner diameter 6.4mm) | |||||

| USS-PP116 | For 35# tubing (thickness 2.4mm, inner diameter 7.9mm) | |||||

| USS-PP117 | For 36# tubing (thickness 2.4mm, inner diameter 9.6mm) | |||||

| Replacement | Model | Material | Inner Diameter | Outer Diameter | Length | Applicable Tubing |

| Straight Connectors | USS-PP118 | PP | 4.8mm | 9mm | 39mm | 15# |

| USS-PP119 | 5.9mm | 10.5mm | 46mm | 24# | ||

| USS-PP120 | 7.5mm | 11.8mm | 46mm | 35# | ||

| USS-PP121 | 8.9mm | 13.4mm | 48mm | 36# | ||

*To view the full table on mobile, please swipe left or right on the screen.