Introduction

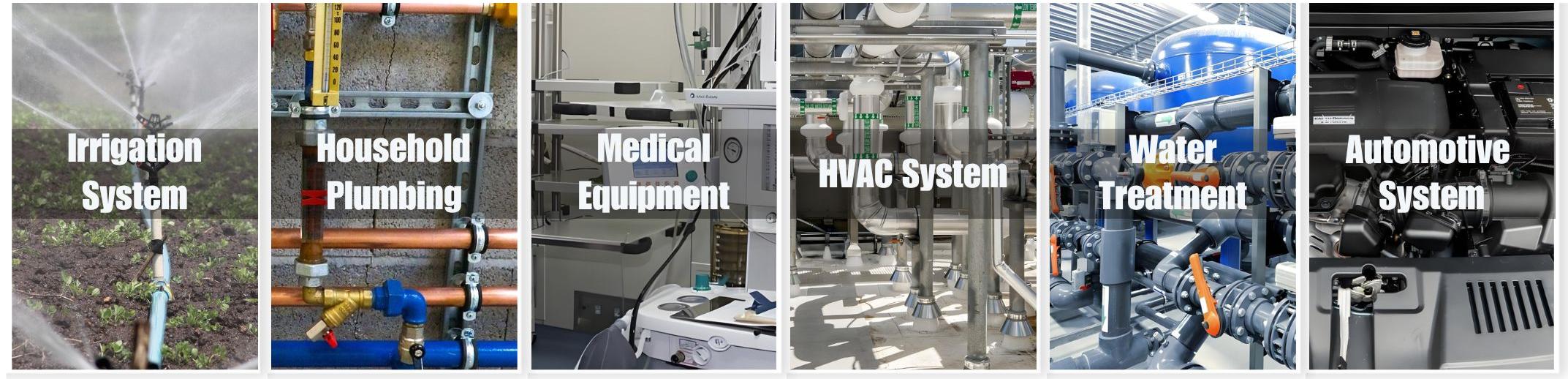

A solenoid valve is a key component in fluid control systems, used in applications like irrigation, combustion engines, and pneumatic systems. It uses an electrical signal to activate a solenoid coil, generating a magnetic field that moves a plunger to open or close the valve. This allows for quick and precise control of fluid or gas flow, making solenoid valves essential for efficient system operation.

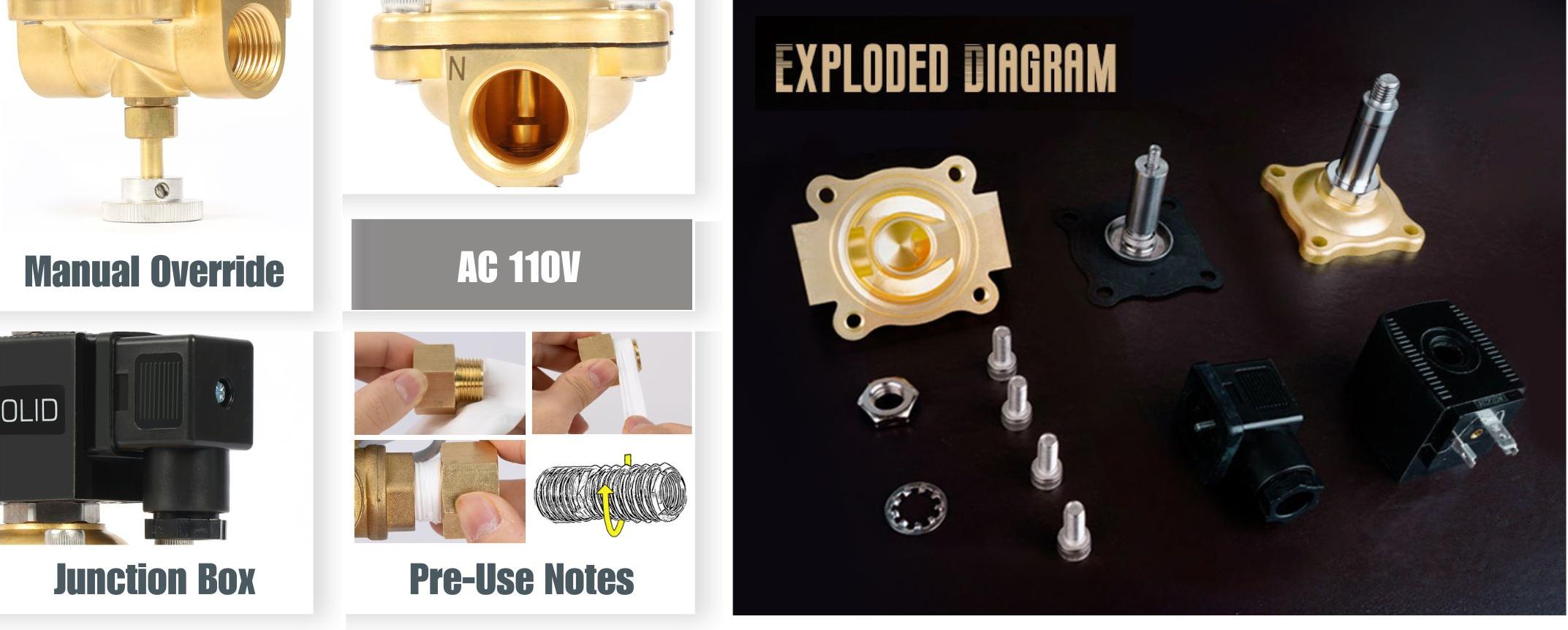

This model has a manual override (unlike the base model solenoid valve) – allows manual operation when power is off.

With a junction box connection, it offers secure wiring protection, making it ideal for harsh environments where dust, moisture, or vibration may be a concern.

Applications

Features

- Manual Override: Built-in override feature allows manual operation of the valve when electrical power is unavailable.

- Junction box: Provides secure wiring protection for harsh environments (dust, moisture, vibration).

- Normally Closed: Closed when unpowered, opens when energized.

- NPT / G: NPT (National Pipe Taper) and G (BSPP) threading to accommodate diverse global specifications, ensuring a secure seal with teflon tape.

- Valve Body Material: Constructed from robust brass. Not suitable for drinking water applications.

- Rapid Response Time: Opens/closes in under a second, with a lifespan of over a million cycles when maintained properly.

- Low-pressure Starting: Designed for low-pressure starting, this valve can operate with minimal pressure, less than 0.1 bar, ensuring versatility in low-pressure conditions.

- Viton Seal: Featuring a durable Viton seal, this valve can withstand high temperatures and resist corrosive chemicals and fluids like gasoline, oils, diesel and lubricants.

- Direct-acting: Simple, fast-response, and works from zero pressure.

User Manual

To learn how to use this product, please refer to the user manual.

Technical Data

| Model | USS-YSV10004/USS-YSV10004-G | Port Size | 1/2" | ||

| Thread Type | NPT/G | Body Material | Brass | ||

| Operation Type | Direct | Wiring Type | Junction Box | ||

| Operation Mode | Normally Closed | Flow Aperture | 15 mm | ||

| Flow value | 4.8 Cv | Gasket/Diaphragm/Seal | VITON | ||

| Operating Time | ≤1s | Rated Voltage | AC 110V/AC 220V | ||

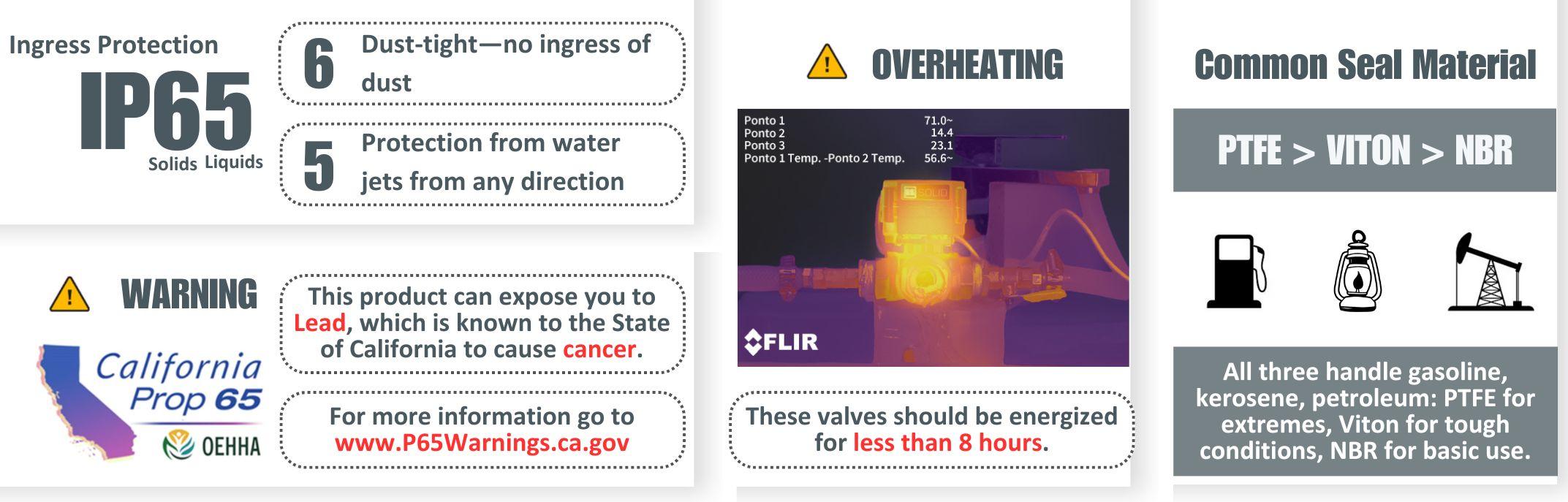

| IP Rating | IP65 | Power | 16W | ||

| Operating Temperature | -22℉-302℉(-30℃-150℃) | Suitable Liquid Viscosity | 20 cst Below | ||

| Operating Pressure | 0.0-0.4 MPa | Suitable Media | Air, water, diesel oil, kerosene, etc. | ||

| Net Weight | 1.48 lbs | Package Dimensions | 5.43"x4.33"x3.62" | ||

*To view the full table on mobile, please swipe left or right on the screen.

FAQ

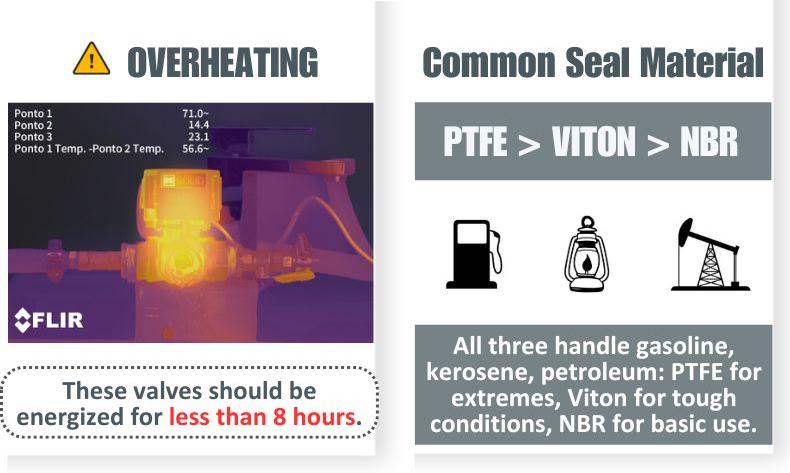

Problem 1: Which sealing material, VITON or NBR, is more suitable for use with gasoline, kerosene, or other petroleum products?

VITON. It is the better choice due to its excellent resistance to high temperatures, chemicals, and fuels. For long-term or demanding applications, VITON outperforms NBR.

Problem 2: Can these solenoid valves be used continuously for extended periods?

These valves should be energized for less than 8 hours. While most do not exceed 18W of power, the coils are in a contained area and can burn out if energized for too long. We recommend using a computer fan to keep the coil cool if continuous operation is necessary.

Problem 3: How long should you wait between two consecutive five-hour uses of our solenoid valve?

It is recommended to allow about 20 minutes of cooling time between two consecutive 5-hour operating sessions. The exact cooling time may vary depending on ambient temperature and operating conditions.

Problem 4: How long does a solenoid valve last?

With a lifespan of over a million cycles when maintained properly, the actual longevity may vary depending on factors such as operating conditions, fluid type, pressure, temperature, and maintenance practices.

Problem 5: Can this be used for Drinking Water?

NO. This solenoid valve is made of brass, which contains lead, should not be used for drinking water.

Problem 6: Can it be used outdoors?

While the solenoid valves have an IP65 rating, making them resistant to water spray, it is recommended to enclose the valve in a protective housing if permanently installed outdoors to ensure long-term durability.

Problem 7: What does the arrow on the valve body indicate?

The arrow on the valve indicates the flow direction. Most U.S. Solid valves are unidirectional, meaning they are designed to operate correctly only when fluid flows in the direction of the arrow. If installed in the opposite direction, the valve may not function properly (e.g., a Normally Closed valve may fail to close).

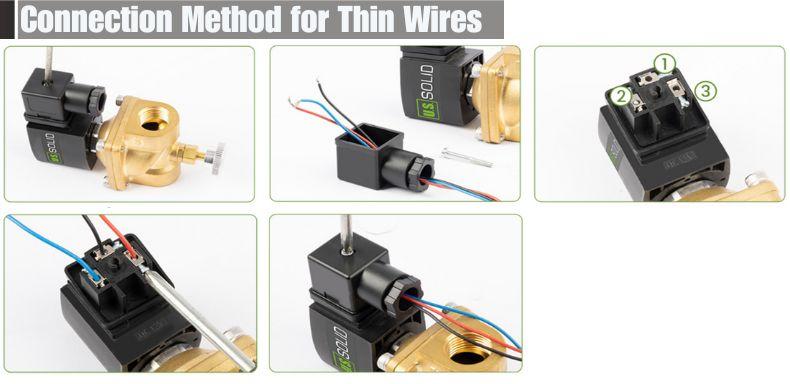

How to Wire

*Note: Terminal ① (top) is for the ground wire, while terminals ② and ③ (bottom) can be wired to either L(+) or N(-) in any order.