How to Choose Normally Open and Normally Closed Motorized Ball Valves

Share

Motorized ball valves are a vital piece of equipment in numerous applications. Most solenoid valves are energized continuously when in a new position, while motorized ball valves expend energy only when changing from open to close, or vice versa. Motorized ball valves are widely used in various industrial systems, water treatment, HVAC, and even household water supply systems due to their fast opening and closing speeds, good sealing performance, and easy operation. When selecting an electric ball valve, one of the most critical decisions is choosing between a normally open (NO) type and a normally closed (NC) type. This choice directly affects the safety, stability, and energy efficiency of the entire system. Below, we will detail the selection criteria from the definition, core considerations, and practical application scenarios.

1. First, Clarify the Definitions: What Are Normally Open and Normally Closed Motorized Ball Valves?

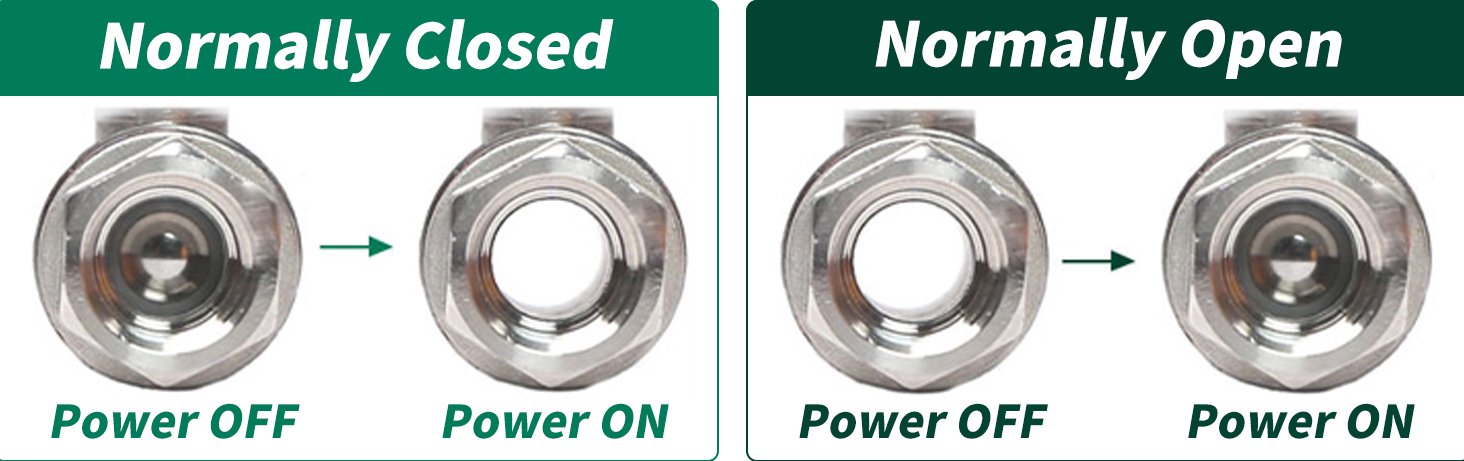

Before making a choice, it is essential to understand the fundamental difference between the two types, which is determined by the state of the valve core when the power is cut off (excluding manual operation). The following image illustrates the key characteristics of NO and NC electric ball valves:

- Normally Open (NO): When the power supply is cut off, the valve remains in the fully open state. Only when an electric signal is received (power is turned on) will the valve drive the core to rotate and close, blocking the medium flow. After the power is cut off again, it will automatically return to the open state under the action of a spring or other reset mechanisms.

- Normally Closed (NC): In contrast, when the power is cut off, the valve is in the fully closed state. It requires an electric signal (power on) to drive the core to rotate and open, allowing the medium to flow. Once the power is cut off, it will automatically close to block the medium.

2. Core Selection Criteria: Starting from System Safety and Functional Requirements

The choice between normally open and normally closed types is not arbitrary; it is based on the system's fault state requirements and daily operation logic. The following four key factors need to be focused on:

Factor 1: Priority of "Safety State" After Power Failure

This is the most important criterion. In case of unexpected power failure (a common fault in the system), the valve's state must ensure that the system does not cause safety accidents (such as leakage, over pressure, or equipment damage).

-

Choose Normally Open (NO): After power failure, the medium needs to "continue flowing" to avoid danger. For example:

- Cooling water systems in industrial equipment: If the power is cut off, the cooling water must continue to circulate to prevent the equipment from overheating and being damaged. At this time, a normally open electric ball valve should be used to ensure that the cooling water path remains unobstructed after power failure.

- Ventilation pipelines in chemical storage tanks: After power failure, the vent valve needs to stay open to avoid excessive pressure inside the tank due to volatile gas accumulation, which may lead to tank explosion.

-

Choose Normally Closed (NC): After power failure, the medium needs to "stop flowing" to prevent risks. For example:

- Gas supply pipelines in households or factories: In case of power failure, the gas valve must be closed immediately to avoid gas leakage and prevent fire or explosion accidents. A normally closed electric ball valve is the best choice here.

- Chemical reagent delivery pipelines: If the power is cut off during the delivery of toxic or corrosive reagents, the valve must be closed quickly to prevent the reagent from leaking and causing environmental pollution or personal injury.

Factor 2: Matching with Daily Operation Frequency

The type of valve also needs to align with the "daily on-off frequency" of the system to reduce energy consumption and extend the valve's service life.

- Normally Open (NO) is More Suitable: If the system requires the medium to be in a "long-term circulation" state during daily operation, and closing is only a temporary operation (such as occasional maintenance or adjustment). For example, the main water supply pipeline of a residential area: It needs to supply water 24 hours a day, and the valve is only closed when maintenance is required. Choosing a normally open type avoids long-term power consumption (since it only needs to be powered on when closing).

- Normally Closed (NC) is More Suitable: If the system only needs the medium to flow "occasionally" and is in a closed state most of the time. For example, the water inlet valve of a household water heater: It only needs to be opened when the water heater is replenishing water, and remains closed at other times. Choosing a normally closed type can avoid frequent power supply to maintain the open state, saving energy.

Factor 3: Compatibility with System Control Logic

The valve type must match the control system's signal output logic to ensure that the valve can execute instructions correctly (such as automatic control by a PLC or a remote control system).

For example, in an intelligent irrigation system: The system is set to "water at 8 a.m. every day" and "stop watering after 1 hour". If the irrigation pipeline is in a closed state most of the time, a normally closed electric ball valve is more suitable. When the system sends a "watering signal" (power on), the valve opens; after 1 hour, the signal is cut off (power off), and the valve closes automatically. If a normally open valve is used, the system would need to keep sending a "closing signal" (continuous power supply) during non-irrigation periods, which not only increases energy consumption but also may cause valve failure due to long-term power-on.

Factor 4: Consideration of Medium Properties

The physical and chemical properties of the medium (such as viscosity, corrosiveness, and whether it is easy to solidify) will also affect the valve selection.

- For media that are easy to solidify (such as molten asphalt, paraffin): If the valve is closed for a long time, the medium may solidify in the valve core, causing the valve to be stuck and unable to open. In this case, if the system allows, a normally open electric ball valve should be preferred to keep the medium flowing for a long time and avoid solidification.

- For highly corrosive media (such as strong acid and alkali): If the valve is in an open state for a long time, the sealing ring may be corroded by the medium, reducing the sealing performance. If the system only needs to be opened occasionally, a normally closed type can be chosen to minimize the contact time between the sealing ring and the corrosive medium.

In conclusion, the selection of normally open and normally closed electric ball valves is a decision closely related to system safety and efficiency. Only by fully combining the system's fault handling requirements, daily operation habits, and medium characteristics can you choose the most suitable valve type and ensure the stable operation of the entire system.