INTRODUCTION

Introducing our continuous sealer, engineered for consistent, precise results across various materials (0.02–0.16mm thickness). Key specs include a 10mm seal width, 7 m/min speed, and a 0-250℃ temperature range. It boasts rugged, all-metal construction with an electrostatic paint finish, and uses pure copper for heating and cooling blocks to ensure long-term reliability. Operation is simplified by a powerful, user-friendly control panel, making complex setups a thing of the past.

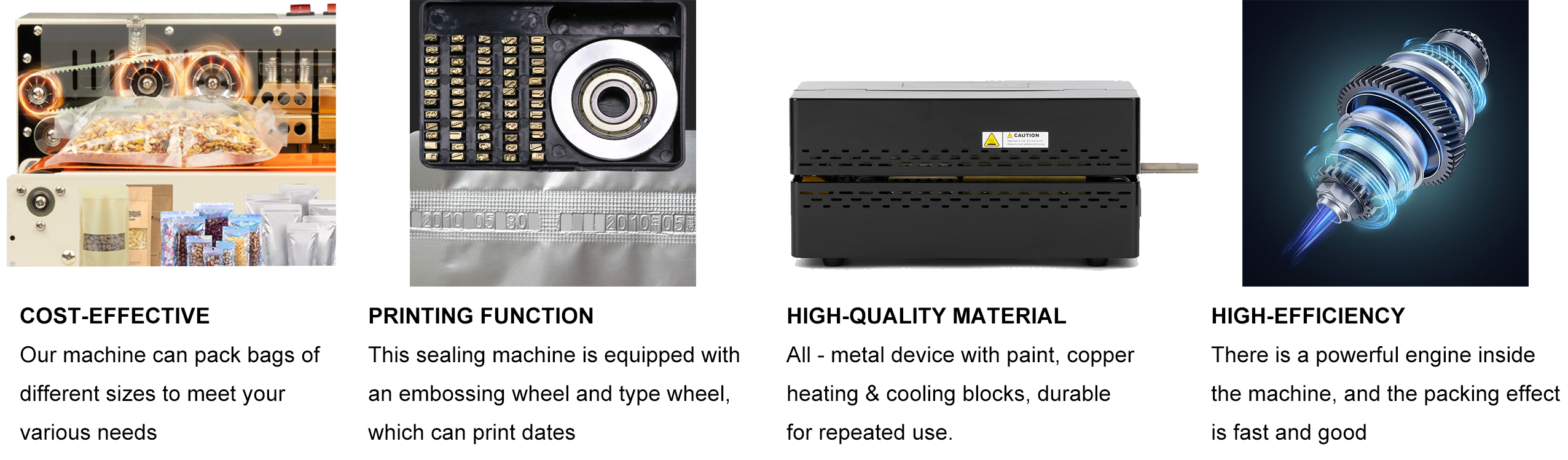

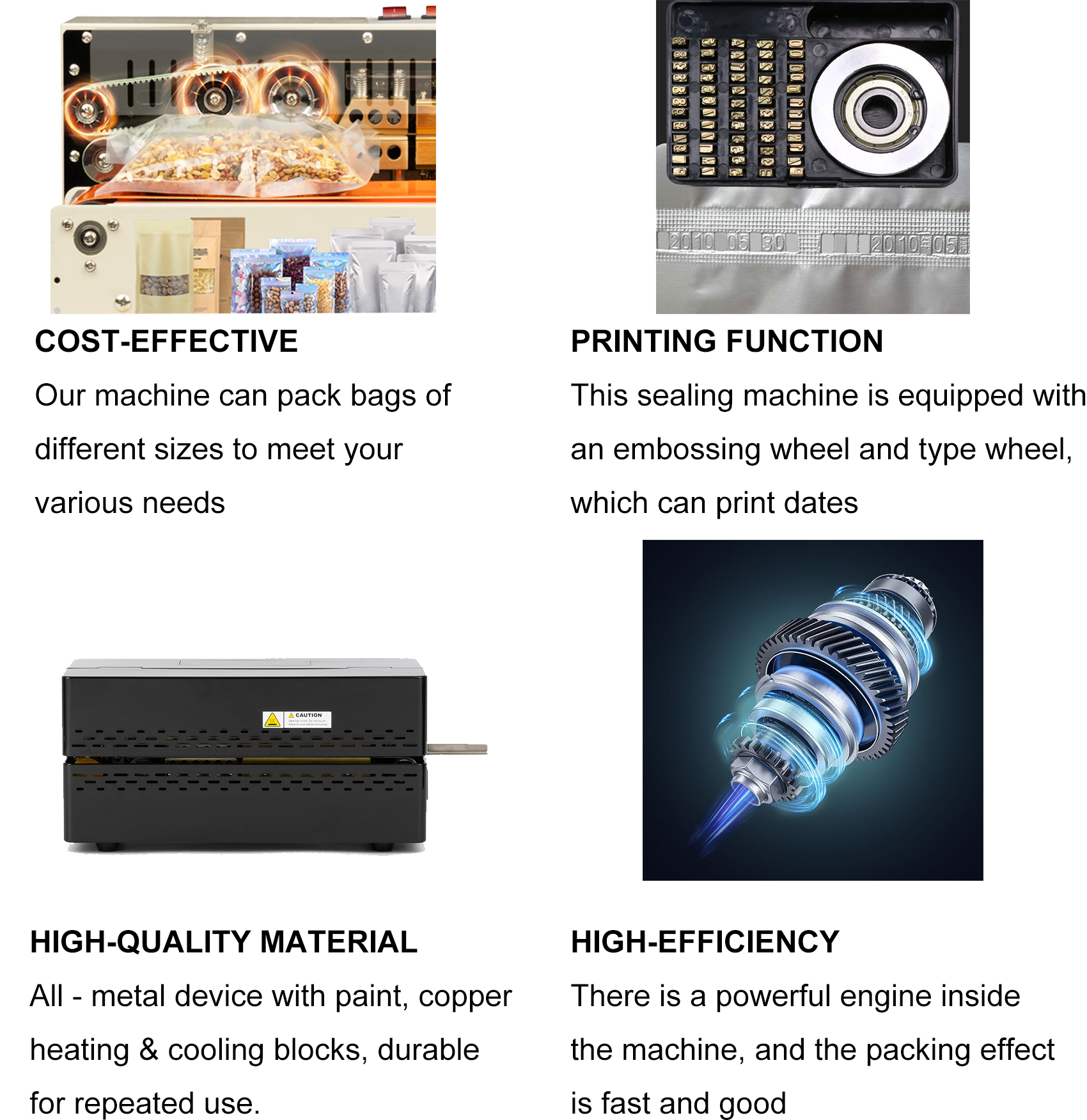

FEATURES

APPLICATIONS

SPECIFICATIONS

| Model | USS-CBB00017 | Brand | U.S. Solid |

|---|---|---|---|

| Power Supply | 110V,60HZ | Power | 450W |

| Sealing Speed | 0 - 7M/min (adjustable) | Sealing Width | 0.39 inch |

| Max. Seal Thickness | 0.006 inch | Temp. range | 0 - 250℃ (adjustable) |

| Counting Function | No | Max. Load Weight | 2.2 lb |

WARNING

1. Ensure the driving wheel and driven wheel are parallel to prevent seal deviation. Regularly check and adjust the screws on the driven wheel.

2. Avoid over-tightening the sealing tape. Adjust the longitudinal adjustment screw to maintain moderate tension.

3. Ensure the compression spring on the embossing wheel seat is properly tightened for clear knurling.

4. Maintain a moderate gap between heating or cooling blocks (approximately one layer of packaging thickness) to reduce friction and ensure smooth operation.

5. Adjust the pressure on intermediate or embossing rollers to avoid bags sticking or turning. Ensure gaps match the packaging thickness for optimal sealing and clarity.

PACKING LIST

- Main Machine x1

- Accessory Bag x1

- User Manual x1

OTHER MODELS

Explore Our Full Range of Band Sealers

We offer a variety of models with different speeds, sealing widths, and load capacities to meet your specific packaging requirements.

VIEW MODEL SELECTION TABLEDownload user manual here

INTRODUCTION

Introducing our continuous sealer, engineered for consistent, precise results across various materials (0.02–0.16mm thickness). Key specs include a 10mm seal width, 7 m/min speed, and a 0-250℃ temperature range. It boasts rugged, all-metal construction with an electrostatic paint finish, and uses pure copper for heating and cooling blocks to ensure long-term reliability. Operation is simplified by a powerful, user-friendly control panel, making complex setups a thing of the past.

FEATURES

APPLICATION

SPECIFICATIONS

| Model | USS-CBB00017 | Brand | U.S. Solid |

|---|---|---|---|

| Power Supply | 110V,60HZ | Power | 450W |

| Sealing Speed | 0 - 7M/min (adjustable) | Sealing Width | 0.39 inch |

| Max. Seal Thickness | 0.006 inch | Temp. range | 0 - 250℃ (adjustable) |

| Counting Function | No | Max. Load Weight | 2.2 lb |

WARNING

1. Ensure the driving wheel and driven wheel are parallel to prevent seal deviation. Regularly check and adjust the screws on the driven wheel.

2. Avoid over-tightening the sealing tape. Adjust the longitudinal adjustment screw to maintain moderate tension.

3. Ensure the compression spring on the embossing wheel seat is properly tightened for clear knurling.

4. Maintain a moderate gap between heating or cooling blocks (approximately one layer of packaging thickness) to reduce friction and ensure smooth operation.

5. Adjust the pressure on intermediate or embossing rollers to avoid bags sticking or turning. Ensure gaps match the packaging thickness for optimal sealing and clarity.

PACKING LIST:

- Main Machine x1

- Accessory Bag x1

- User Manual x1

OTHER MODELS

Explore Our Full Range of Band Sealers

We offer a variety of models with different speeds, sealing widths, and load capacities to meet your specific packaging requirements.

VIEW MODEL SELECTION TABLEDownload user manual here