INTRODUCTION

Experience unparalleled efficiency and speed with our Vertical Automatic Continuous Sealing Machine, engineered for high-speed sealing operations that handle large volumes of packages in minimal time—perfect for high-production industries. A built-in counter function streamlines your packing process, boosting efficiency by automatically tracking counts as you work. With a 13mm seal width, unlimited seal length, and adjustable speed up to 16m/min, it accommodates single-layer bags up to 0.1mm thick, with temperature control ranging from 0-300℃ (572℉) and a maximum load capacity of 13 lbs. Versatile enough to seal various plastic and laminated bags, it’s ideal for food, pharmaceutical, chemical, and other industries. Its compact, durable design ensures reliable performance even in continuous operation, making it a space-saving solution for businesses of all sizes.

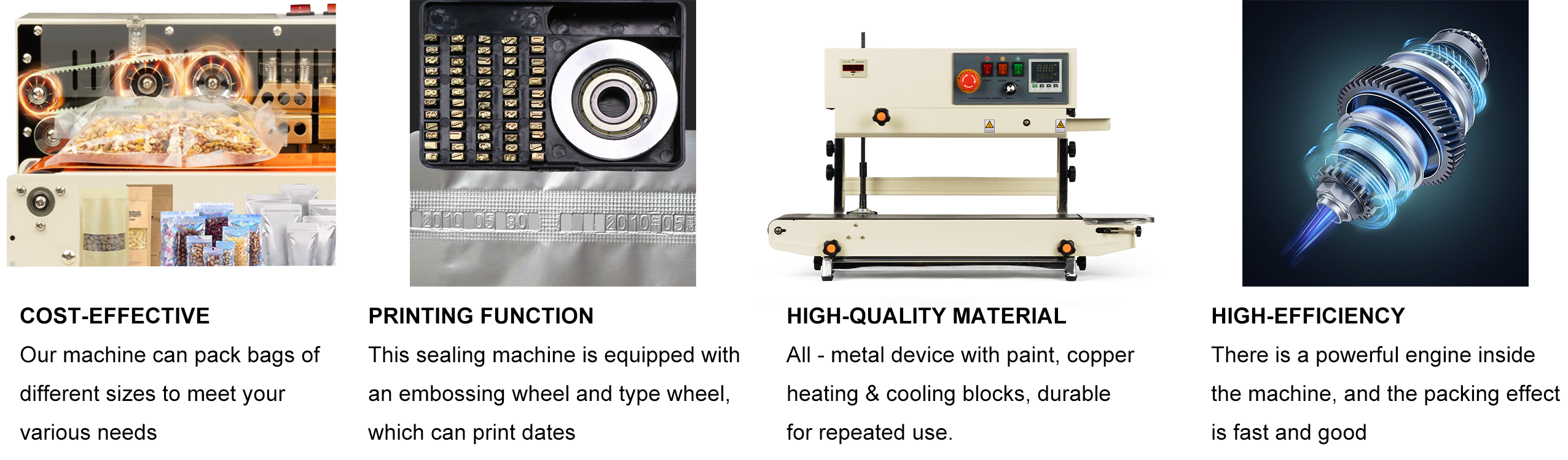

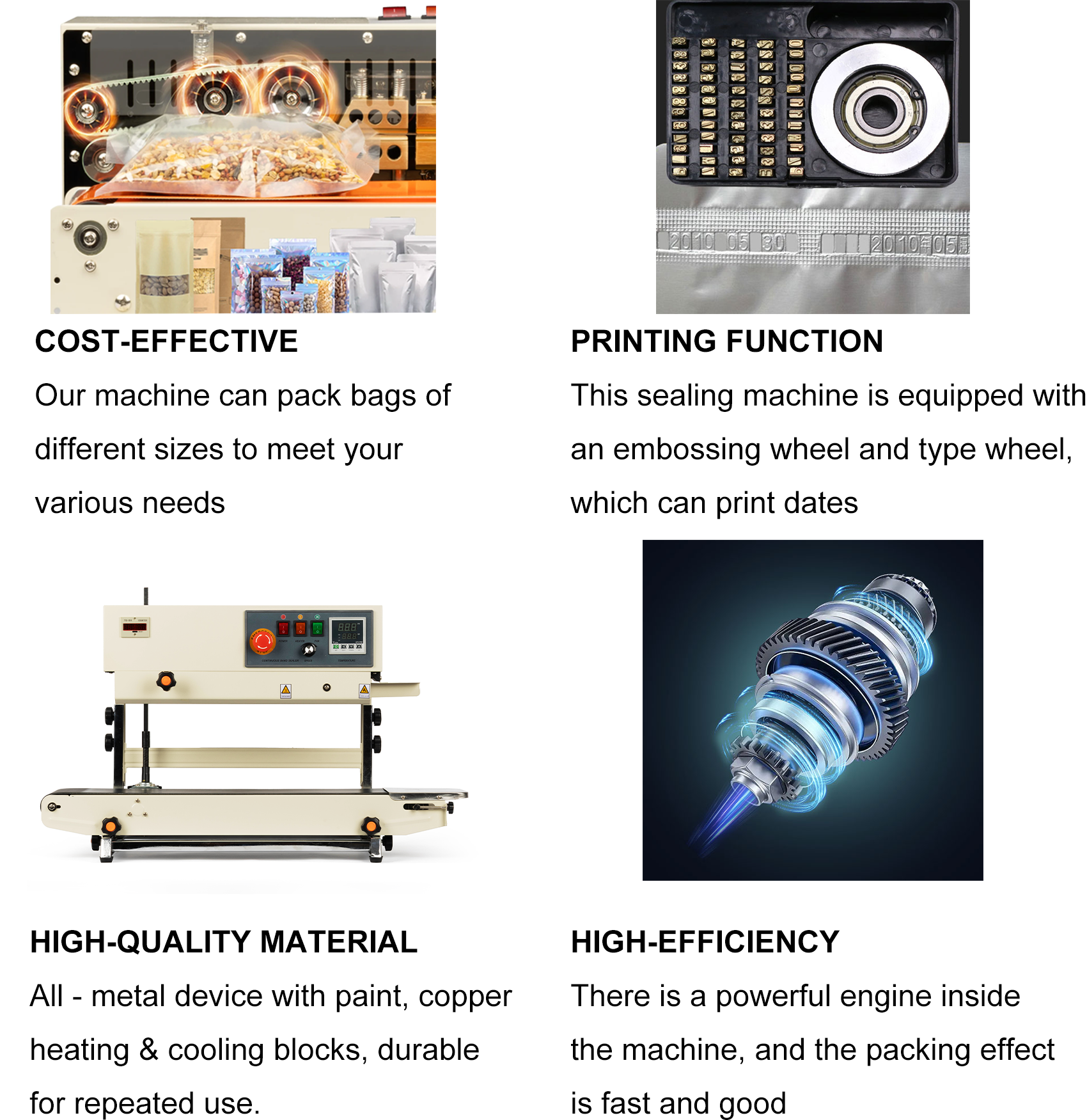

FEATURES

APPLICATIONS

SPECIFICATIONS

| Model | USS-CBB00016 | Brand | U.S. Solid |

|---|---|---|---|

| Power Supply | 110V,60HZ | Power | 750W |

| Sealing Speed | 0 - 16M/min (adjustable) | Sealing Width | 0.05 inch |

| Max. Seal Thickness | 0.03 inch | Temp. range | 0 - 300℃ (adjustable) |

| Counting Function | Yes | Max. Load Weight | 13 lb |

WARNING

1. Ensure the driving wheel and driven wheel are parallel to prevent seal deviation. Regularly check and adjust the screws on the driven wheel.

2. Avoid over-tightening the sealing tape. Adjust the longitudinal adjustment screw to maintain moderate tension.

3. Ensure the compression spring on the embossing wheel seat is properly tightened for clear knurling.

4. Maintain a moderate gap between heating or cooling blocks (approximately one layer of packaging thickness) to reduce friction and ensure smooth operation.

5. Adjust the pressure on intermediate or embossing rollers to avoid bags sticking or turning. Ensure gaps match the packaging thickness for optimal sealing and clarity.

6. When using the machine for the first time, please turn the emergency switch upward to unlock it.

PACKING LIST

- Main Machine x1

- Accessory Bag x1

- User Manual x1

OTHER MODELS

Explore Our Full Range of Band Sealers

We offer a variety of models with different speeds, sealing widths, and load capacities to meet your specific packaging requirements.

VIEW MODEL SELECTION TABLEDownload user manual here

INTRODUCTION

Experience unparalleled efficiency and speed with our Vertical Automatic Continuous Sealing Machine, engineered for high-speed sealing operations that handle large volumes of packages in minimal time—perfect for high-production industries. A built-in counter function streamlines your packing process, boosting efficiency by automatically tracking counts as you work. With a 13mm seal width, unlimited seal length, and adjustable speed up to 16m/min, it accommodates single-layer bags up to 0.1mm thick, with temperature control ranging from 0-300℃ (572℉) and a maximum load capacity of 13 lbs. Versatile enough to seal various plastic and laminated bags, it’s ideal for food, pharmaceutical, chemical, and other industries. Its compact, durable design ensures reliable performance even in continuous operation, making it a space-saving solution for businesses of all sizes.

FEATURES

APPLICATION

SPECIFICATIONS

| Model | USS-CBB00016 | Brand | U.S. Solid |

|---|---|---|---|

| Power Supply | 110V,60HZ | Power | 750W |

| Sealing Speed | 0 - 16M/min (adjustable) | Sealing Width | 0.05 inch |

| Max. Seal Thickness | 0.03 inch | Temp. range | 0 - 300℃ (adjustable) |

| Counting Function | Yes | Max. Load Weight | 13 lb |

WARNING

1. Ensure the driving wheel and driven wheel are parallel to prevent seal deviation. Regularly check and adjust the screws on the driven wheel.

2. Avoid over-tightening the sealing tape. Adjust the longitudinal adjustment screw to maintain moderate tension.

3. Ensure the compression spring on the embossing wheel seat is properly tightened for clear knurling.

4. Maintain a moderate gap between heating or cooling blocks (approximately one layer of packaging thickness) to reduce friction and ensure smooth operation.

5. Adjust the pressure on intermediate or embossing rollers to avoid bags sticking or turning. Ensure gaps match the packaging thickness for optimal sealing and clarity.

6. When using the machine for the first time, please turn the emergency switch upward to unlock it.

PACKING LIST:

- Main Machine x1

- Accessory Bag x1

- User Manual x1

OTHER MODELS

Explore Our Full Range of Band Sealers

We offer a variety of models with different speeds, sealing widths, and load capacities to meet your specific packaging requirements.

VIEW MODEL SELECTION TABLEDownload user manual here