INTRODUCTION

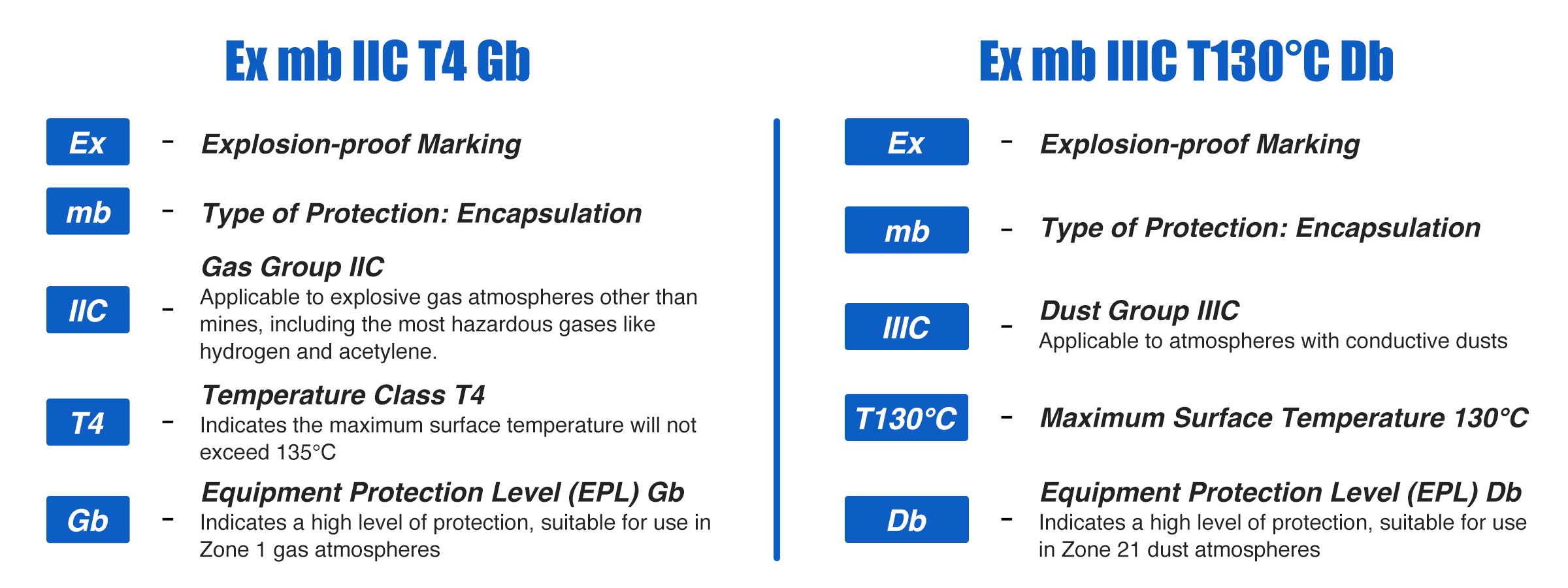

The U.S. Solid Explosion-proof Solenoid Valve is a robust industrial control solution designed for hazardous environments, constructed with a durable brass body and a chemical-resistant Viton seal that makes it suitable for safely managing media such as air, water, light oils, and combustible gases. Engineered for maximum safety, the valve utilizes a zinc alloy coil shell with full epoxy resin encapsulation to prevent sparking and isolate internal components, achieving explosion-proof ratings of Ex mb IIC T4 Gb and Ex mb IIIC T130°C Db. This design allows the valve to operate reliably in Zone 1 and Zone 2 explosive gas atmospheres (Groups IIA, IIB, IIC) as well as Zone 21 and Zone 22 dust environments; however, users must strictly adhere to the coil’s specific ambient temperature range of -20°C to +45°C, which differs from the higher thermal limits of the brass and Viton components, to ensure the integrity of the explosion-proof certification and the internal thermal protection system.

FEATURES

APPLICATIONS

SPECIFICATIONS

| Model | USS-HSV03001 | Connection Size | 1/2" |

|---|---|---|---|

| Valve Material | Brass | Coil Material | Zinc alloy |

| Cv | 4.5 | Orifice (mm) | 15 |

| Media Temperature | <140℉ | Coil-housing Temperature | <266℉ |

| Working Pressure | 0-0.8 MPa | Seal Material | Viton |

| Power | 18W | Volts | 24V DC |

| Compatible Media | Water, Oil, Alcohol etc. | Waterproof Grade | IP65 |

HOW TO USE

WARNING

1.To ensure safe operation and optimal performance, please strictly adhere to the following three temperature limits for this explosion-proof solenoid valve. First, the Ambient Temperature must be maintained within the range of -4°F to 113°F (-20°C to +45°C). Second, the Media Temperature flowing through the valve must remain below 140°F (60°C). Finally, please be aware that the valve generates heat during normal operation; therefore, the Coil Housing Temperature must never exceed 266°F (130°C).

2.Before use, carefully confirm that the power supply voltage matches the coil's voltage rating. Failure to do so will cause irreversible damage to the coil.

3.The coil's lead-in cable is a three-core type. One of these cores, which is bicolored yellow-and-green, is the dedicated ground wire. The coil is equipped with both internal and external grounding screws; it must be reliably connected to ground before use.

4.During installation, the free end of the cable must be terminated inside an explosion-proof junction box or other equipment appropriate for the operating environment.

5.The power supply must be disconnected before performing any on-site installation, disassembly, or maintenance.

FAQ

Q: What is the working principle of this explosion-proof solenoid valve?

A: The working principle of the explosion-proof coil is that when powered on, it generates suction force to move the valve core, and when powered off, the valve core returns to its original position.

Q: What is the material of this explosion-proof solenoid valve coil?

A: The housing of this product is made of zinc alloy, with internal components such as coils, pins, and protective circuit boards. It is potted with epoxy resin that is voltage-resistant, arc-resistant, high-low temperature resistant, and moisture-proof, achieving full sealing without spark generation. Its explosion-proof performance is superior to other similar products. Built-in components such as fuse tubes, varistors, and temperature protection enhance explosion-proof performance, ensuring stable and reliable operation.

Download user manual here.