Introduction

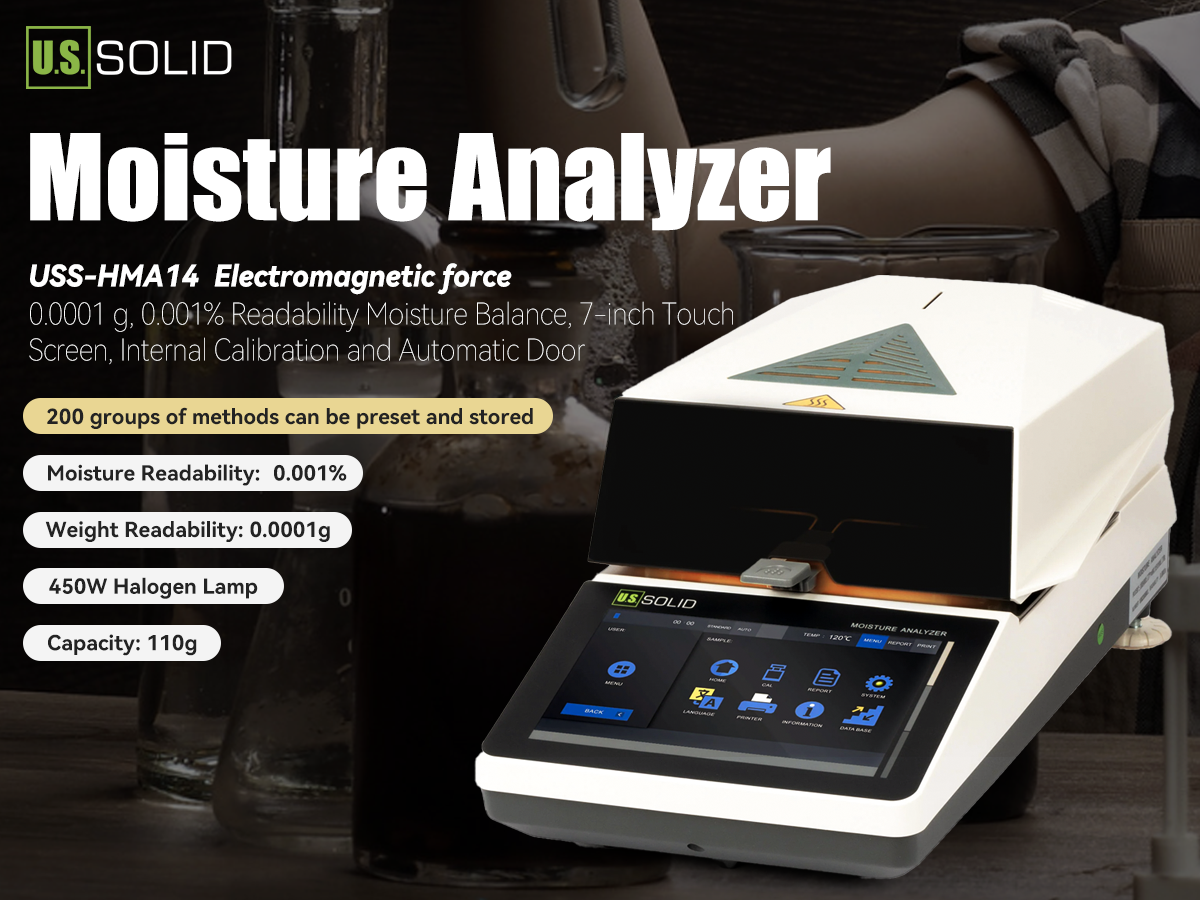

The U.S. Solid USS-HMA14 Moisture Analyzer provides a high level of operating convenience and response sensitivity to facilitate determination of the moisture content of your samples.

It comes with smart functionalities that allows you to preset and store measuring methods, so you can access the options with ease. The device features a 450W halogen lamp and a electromagnetic force transducer that delivers fast and accurate results even on low-moisture samples. USS-HMA14 moisture balance incorporates a high-definition 7-inch LCD color touch-panel that displays with higher accuracy and clarity any test result than general panel. Compact, practical, and easy to use, this moisture balance is a better choice for every lab.

Moisture analyzers work according to the thermogravimetric principle. Moisture is determined by the direct weight lost by the sample due to heating from an intense halogen light.

Applications

Features

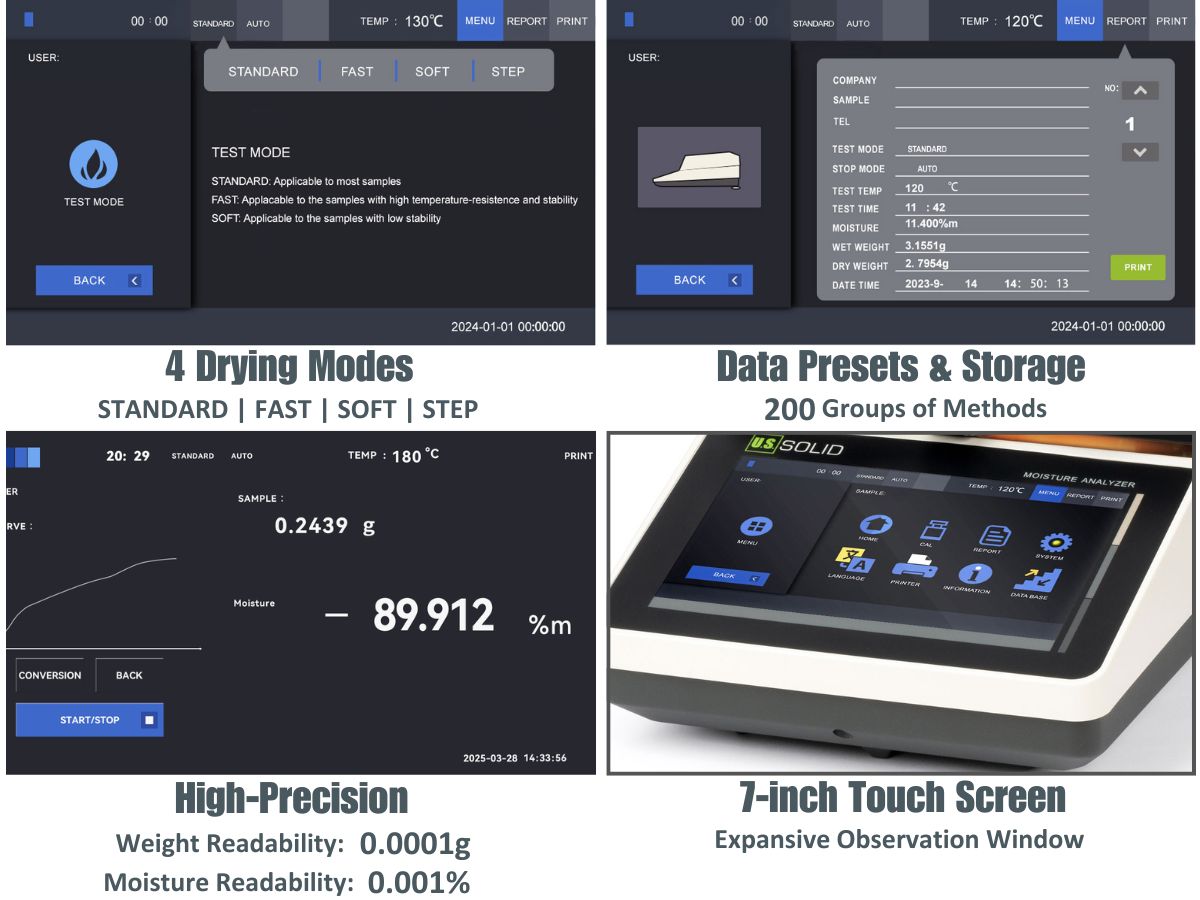

- Readability: 0.0001g (0.1mg)

- Moisture readability: 0.001%

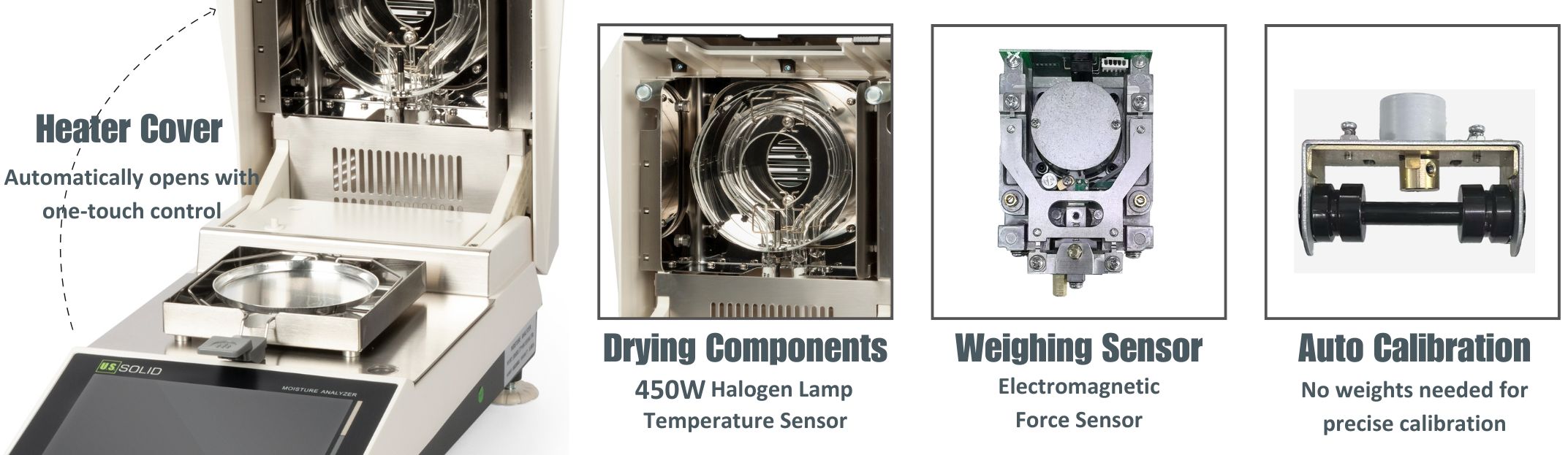

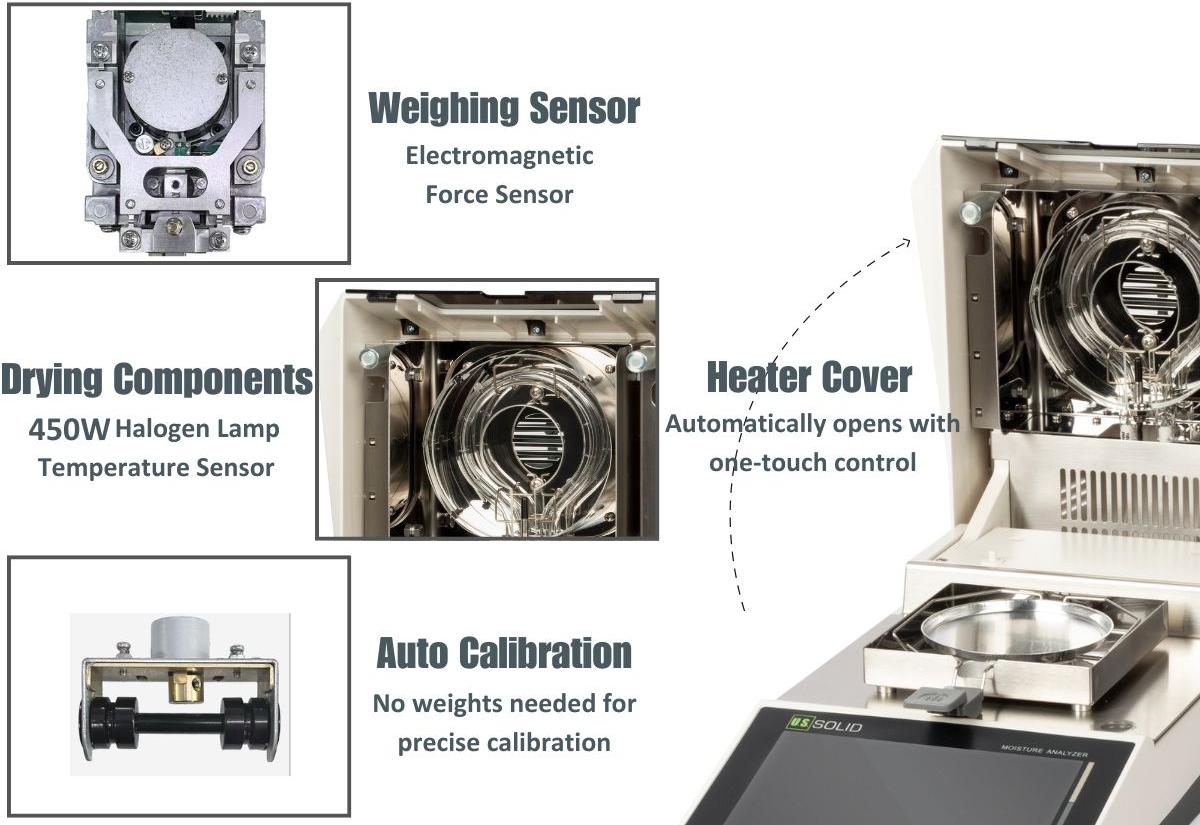

- Automatic calibration

- Electromagnetic force transducer

- Automatic door mechanism: Features a convenient automatic door that can be operated via touch commands on the screen.

- 7-inch LCD color touch-panel: Displays real-time testing curve

- Precise temperature control: Adjustable from 40°C to 200°C in 1°C increments

- Noise control: Silent fan ensures a quiet testing environment

- User authentication: Allows setting up an admin and multiple operators, each with unique passwords for secure access to testing data.

- 4 drying modes (standard/fast/soft/step)

- 3 ending modes (automatic/manual/timing)

- 200 groups of methods can be preset and stored

- 3 kinds of result display (moisture percentage/dry weight/dry-weight percentage)

- 50 sample pans included

More Details

User Manual

For detailed information on calibration, installation, setup, and usage, please refer to the user manual or watch the tutorial video.

Technical Data

| Model | USS-HMA14 | Calibration | Automatic |

| Capacity | 110 g | Displays of results | [%m]/ [%]/ [g] |

| Weight Readability | 0.0001 g | Calibration Weight | 100 g |

| Moisture Readability | 0.001 % | Stabilization Time | ≤ 3s |

| Heating Element | 450W Halogen Lamp | Pan size | Φ100mm |

| Operating temperature range | 104℉-392℉ (40℃-200℃) | Interface | RS-232 |

| Ambient temperature range | 41℉-95℉ (5℃-35℃) | Heater Cover | Automatic |

| Time setting range | 1 - 99 min | Power | 110V 60Hz AC |

| Drying mode | Standard/ Fast/ Soft/ Step | Product dimensions | 7.8*16.5*7.5 inches(200*420*190 mm) |

| Ending mode | Auto/ Timing/ Manual | Net weight | 16.78 lbs (7.61 kg) |

Troubleshooting

Problem 1: Display remains off after switching on.

Possible causes: Power cord is not connected/ Power line fuse blown/ Power supply interrupted/ Instrument faulty

Problem 2: Display does not change when loading samples.

Possible causes: The sample pan/pan holder is not installed correctly.

Problem 3: Weight display is constantly changing or unstable.

Possible causes: The sample pan is in contact with the draft shield or heating chamber/ Air movement/ Test bench vibration/ Electromagnetic field interference

Problem 4: Drying does not start.

Possible causes: Heating chamber open/ Power cord is not connected/ Power line fuse blown

Problem 5:Measurement takes too long.

Possible causes: Incorrect ending mode selected

Problem 6: Measurements are not repeatable.

Possible causes: The samples are not homogeneous./ Drying time is too short./ The temp selected is too high and the sample has been oxidized./ The temperature sensor is contaminated or defective./ The sample is not completely dry.

All Options

| Model | USS-HMA01 | USS-HMA02 | USS-HMA03 | USS-HMA11 | USS-HMA12 | USS-HMA13 | USS-HMA14 | USS-HMA21 | USS-HMA22 | USS-HMA23 |

| Positioning | Mainstream | High-end | Economical | |||||||

| Weight Readability | 0.005 g | 0.001 g | 0.001 g | 0.001 g | 0.001 g | 0.0001 g | 0.0001 g | 0.01 g | 0.005 g | 0.001 g |

| Moisture Readability | 0.1 % | 0.01 % | 0.01 % | 0.01 % | 0.01 % | 0.001 % | 0.001 % | 0.1 % | 0.05 % | 0.01 % |

| Weighing Sensor | High-end strain gauge | High-end strain gauge | Electromagnetic force | Strain gauge | ||||||

| Control Panel | Push Button | Push Button | 5" Touch Screen | 7" Touch Screen | 7" Touch Screen | 7" Touch Screen | 7" Touch Screen | 5" Touch Screen | 5" Touch Screen | 5" Touch Screen |

| Calibration | Manual | Manual | Manual | Manual | Manual | Manual | Auto | Manual | Manual | Manual |

| Heater Cover | Manual | Manual | Manual | Manual | Auto | Auto | Auto | Manual | Manual | Manual |

| Data Storage Group | 15 | 15 | 20 | 200 | 200 | 200 | 200 | 20 | 20 | 20 |

| Temperature Range | 40℃ - 199℃ | 40 ℃ - 200℃ | 40 ℃ - 160℃ | |||||||

| Drying mode | Standard, Fast, Soft | Standard, Fast, Soft, Step | Standard, Fast, Soft | |||||||

| Ending mode | Auto, Timing, Manual | |||||||||

| Pan size | Φ90 mm | Φ100 mm | Φ100 mm | |||||||

| Interface | RS-232 | |||||||||