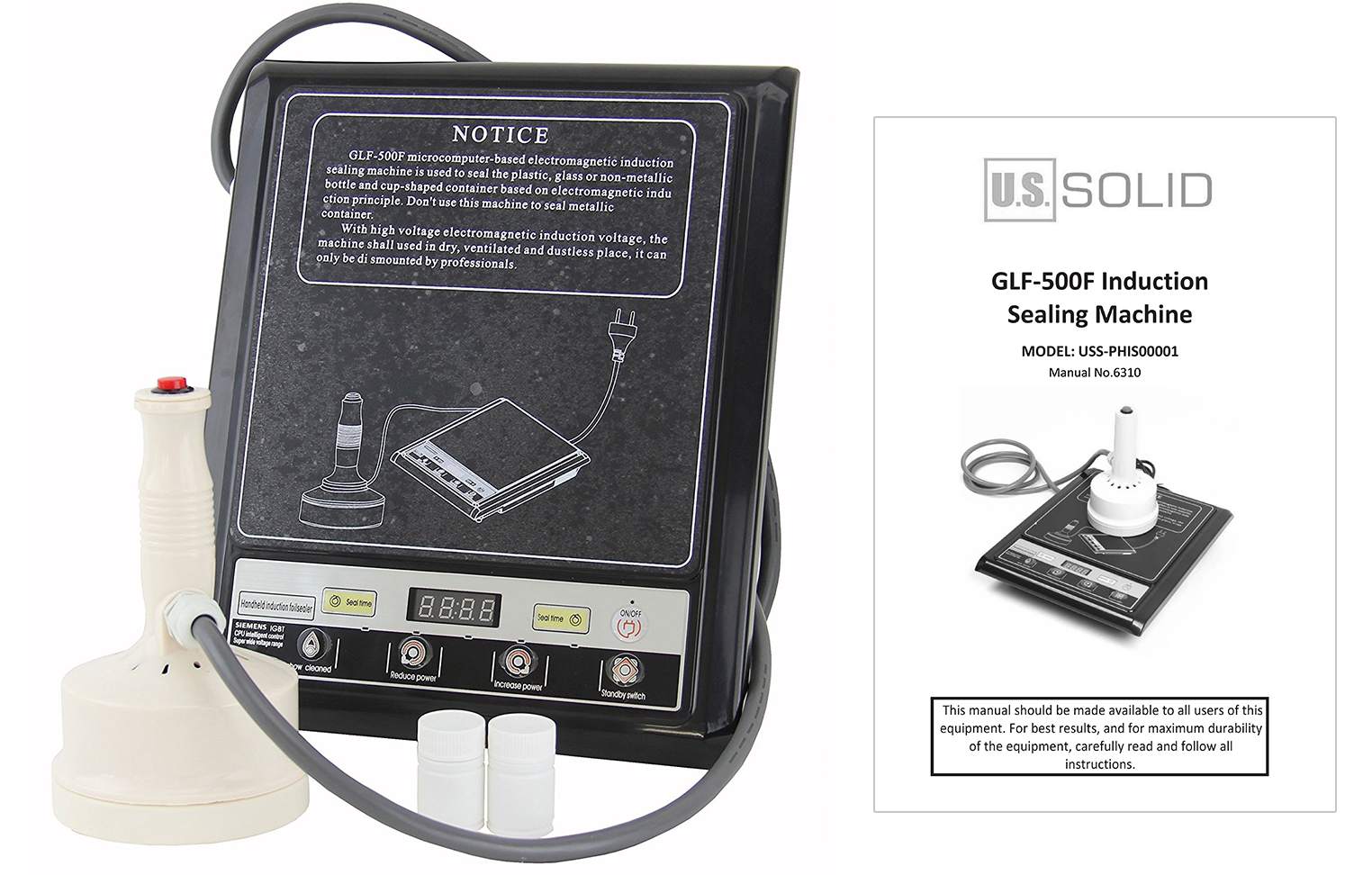

INTRODUCTION

Induction sealing, also known as "cap sealing", is a technique of airtight sealing a liner to the top of a plastic container by utilizing heat produced by an electromagnetic induction device. This method provides evidence of tampering or theft, prevents leaks, and preserves freshness! The U.S. SOLID Portable Handheld Induction Sealer Bottle Cap Sealer works by applying instant high heat to the foil that needs to be melted in order to seal the bottle. It seals the aluminum foil in a matter of seconds to seal plastic (and other non-metallic) bottles and preserve and protect whatever is stored inside.

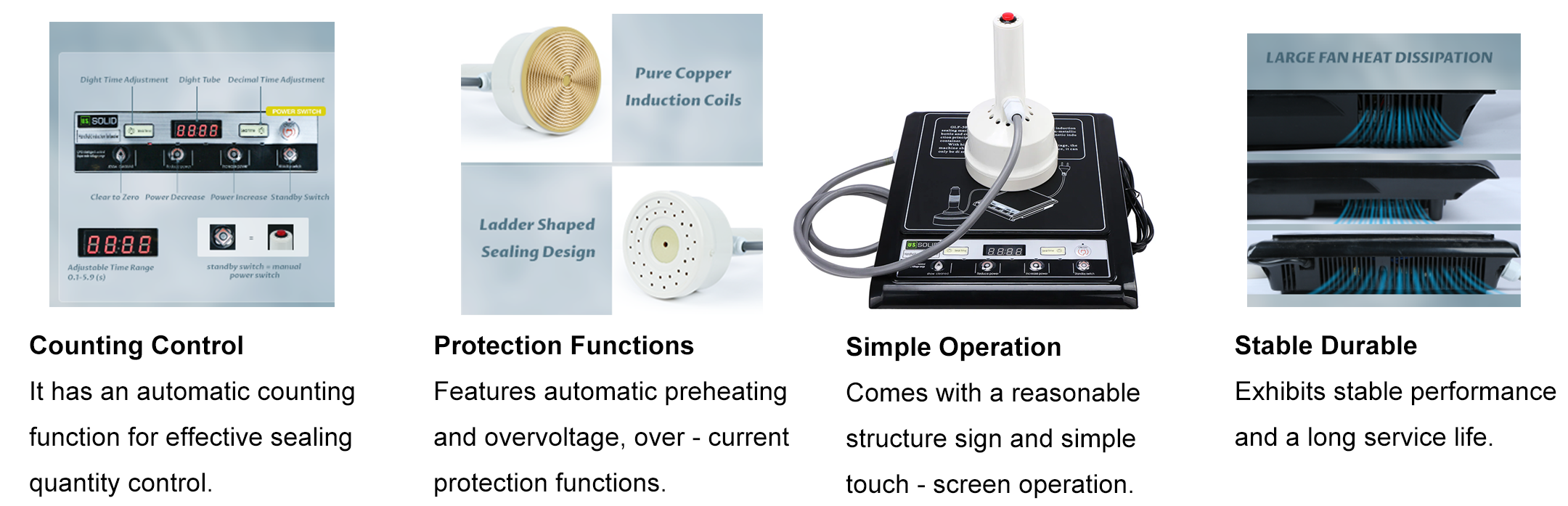

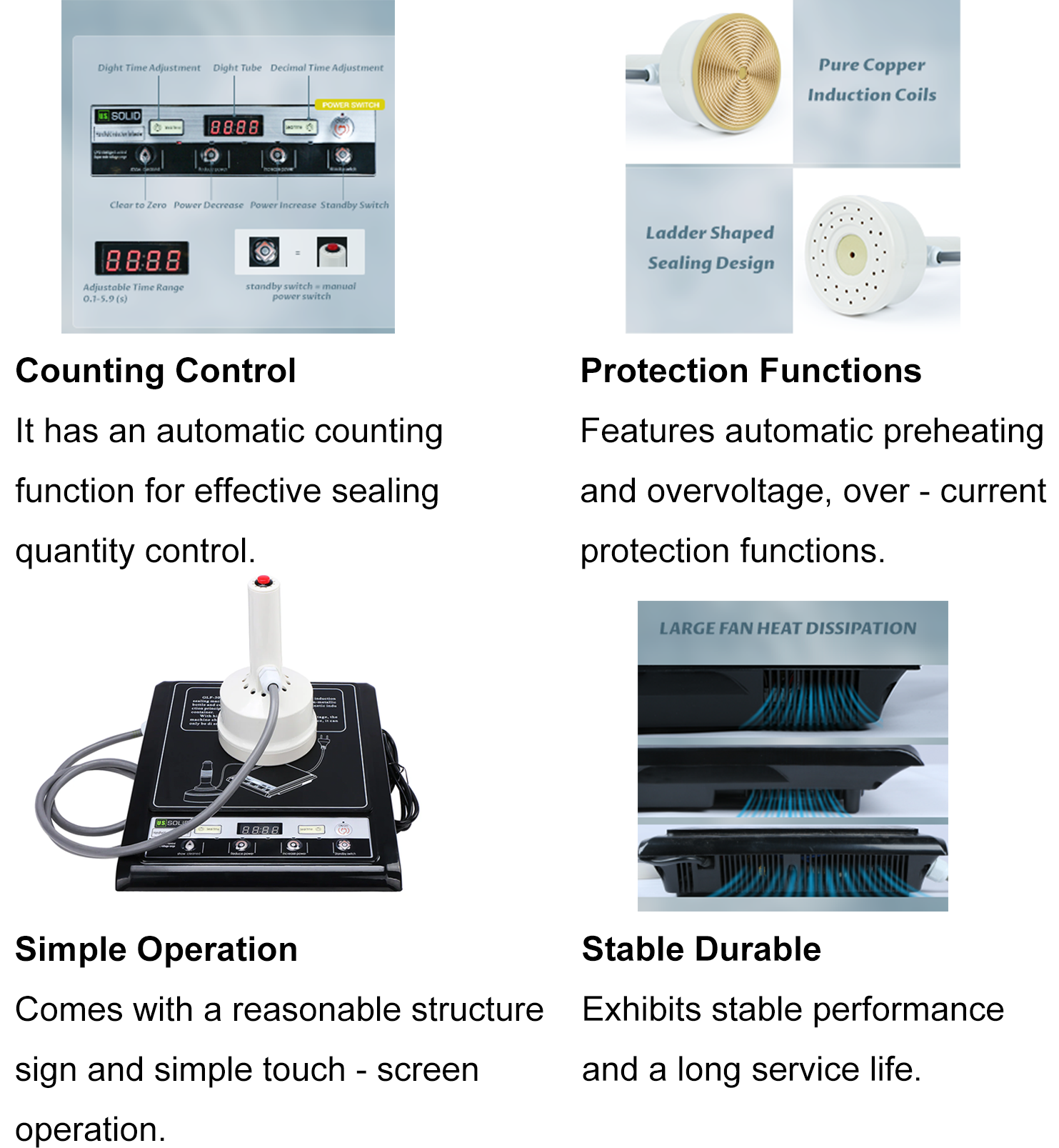

FEATURES

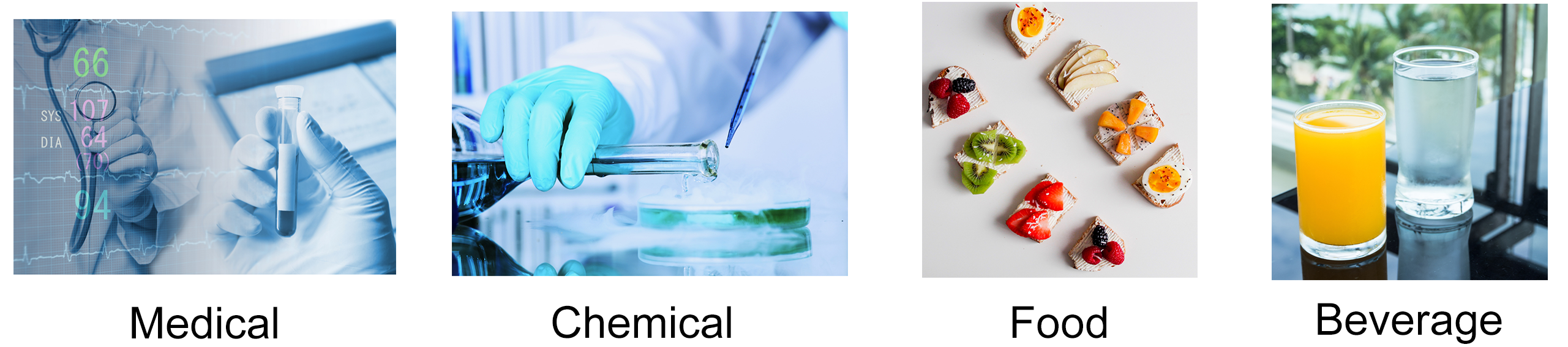

APPLICATIONS

SPECIFICATIONS

| Model | USS-PHIS00001 | Power Consumption | 800 - 1200W |

|---|---|---|---|

| Static current | <0.1 A | Maximum allowable supply current | <6 A |

| Operating frequency | 30 KHz | Relative humidity (RH) | ≤80% |

| Size of Seal: diameter | 15-100 mm | Capacity | 5-20 pcs/min |

| Machine Size | 490*320*135 mm | Net Weight | 4.9 lb |

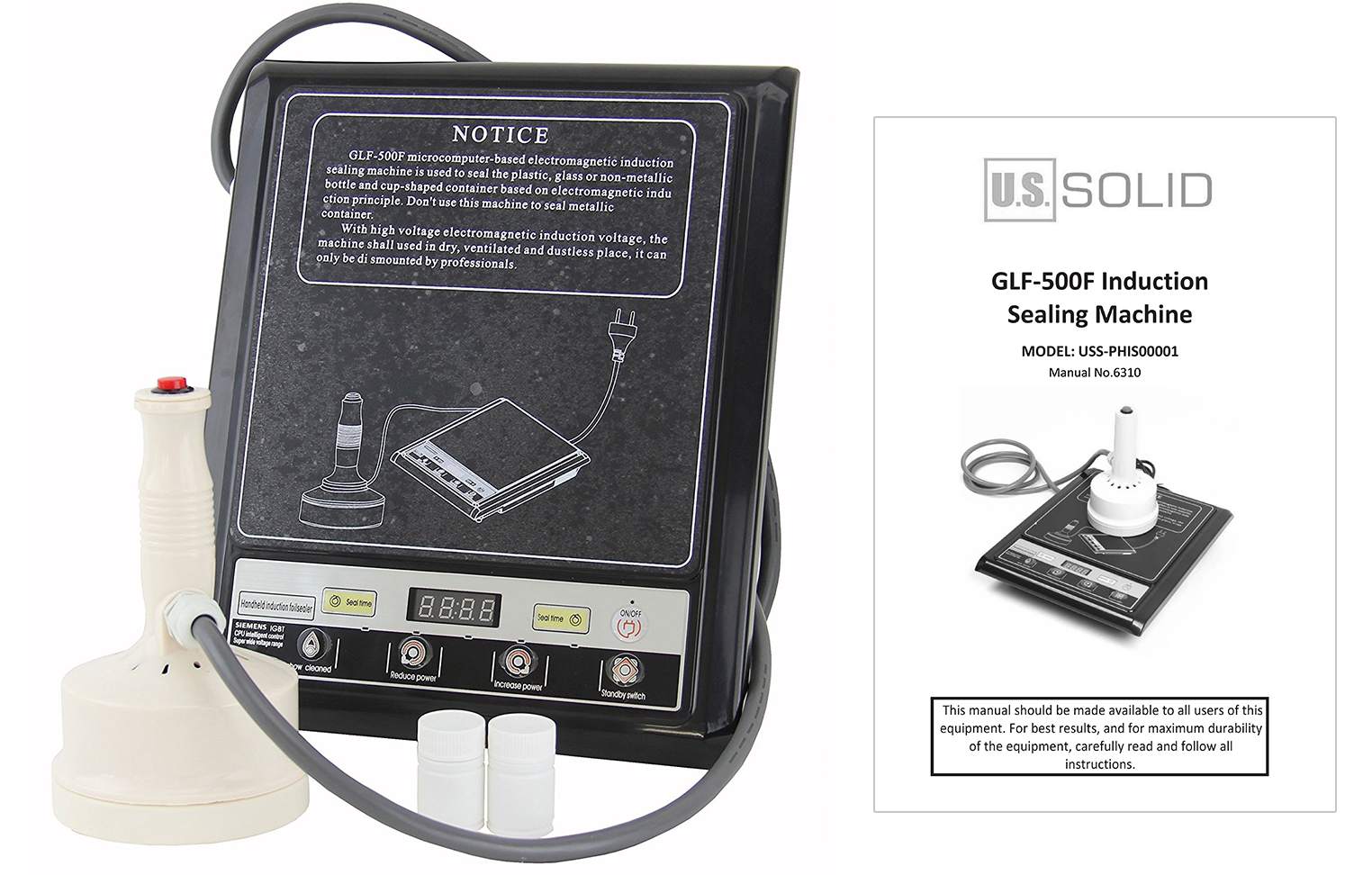

PACKING LIST

- GLF-500 sealing machine x1

- Test bottle x2

- User Manual x1

WARNING

1.The maximum ambient temperature for the equipment operation shall not exceed 45℃, and the humidity shall not exceed 80%.

2.The machine must be used in a well-ventilated place.

3.The induction power supply at the bottom, the heat ventilation holes on the side, and the sensor head must be kept clean and unobstructed to ensure the normal heat dissipation and operation of the equipment.

INTRODUCTION

Induction sealing, also known as "cap sealing", is a technique of airtight sealing a liner to the top of a plastic container by utilizing heat produced by an electromagnetic induction device. This method provides evidence of tampering or theft, prevents leaks, and preserves freshness! The U.S. SOLID Portable Handheld Induction Sealer Bottle Cap Sealer works by applying instant high heat to the foil that needs to be melted in order to seal the bottle. It seals the aluminum foil in a matter of seconds to seal plastic (and other non-metallic) bottles and preserve and protect whatever is stored inside.

FEATURES

APPLICATION

SPECIFICATIONS

| Model | USS-PHIS00001 | Power Consumption | 800 - 1200W |

|---|---|---|---|

| Static current | <0.1 A | Maximum allowable supply current | <6 A |

| Operating frequency | 30 KHz | Relative humidity (RH) | ≤80% |

| Size of Seal: diameter | 15-100 mm | Capacity | 5-20 pcs/min |

| Machine Size | 490*320*135 mm | Net Weight | 4.9 lb |

PACKING LIST:

- GLF-500 sealing machine x1

- Test bottle x2

- User Manual x1

1.The maximum ambient temperature for the equipment operation shall not exceed 45℃, and the humidity shall not exceed 80%.

2.The machine must be used in a well-ventilated place.

3.Heat from material breakdown may damage nearby components. Install heat - resistant shielding or insulation.