INTRODUCTION

This High Frequency Induction Heater enables efficient metalworking by generating electrical currents within conductors like gold, silver, copper, and aluminum, creating precise heat for melting. It offers a constant and stable working temperature, ensuring excellent results.With remarkable features, it has low energy consumption yet high output power, consuming only half the power of traditional electron tube high frequency induction heaters under the same conditions. The 100% load design allows for continuous 24-hour operation.Equipped with the latest MOSFET and IGBT power units and current frequency control standards, it simplifies manual operation. The infrared temperature detector enhances heating quality and automatically controls the temperature. Additionally, the built-in status displays improve reliability and sustainability.

WHY ARE MORE PEOPLE CHOOSING HIGH-FREQUENCY HEATERS?

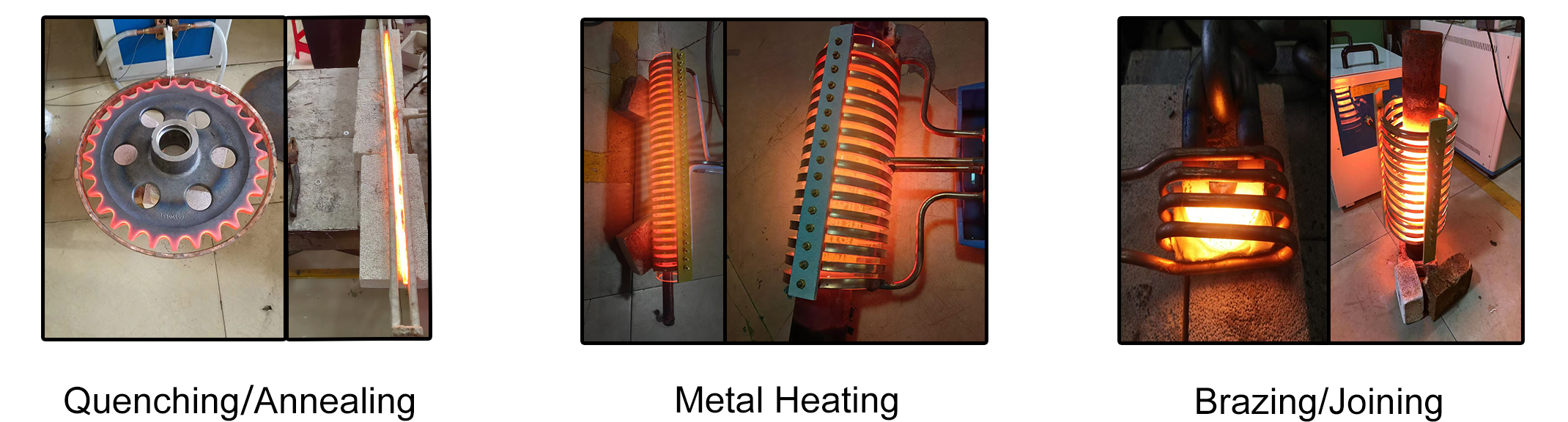

THE MACHINE CAN BE APPLIED IN A VARIETY OF HEAT TREATMENT SCENARIOS

|

|

|

SPECIFICATIONS

| Model | USS-HFIH00001 | Cooling Water Temperature Protection Point | 40°C/104°F |

|---|---|---|---|

| Power Supply | Single phase 110V or 220V | Output Power | 15kW |

| Fluctuating Frequency | 30-80kHz | Interrupting Rating | 40A |

| Turns Ratio (ratio of primary coil turns to secondary coil turns) | 16:1 | Net Weight | 17Kg |

| Output Current | 200-600A | Time Setting | 1-99 seconds |

| Maximum Heating Temperature | up to 1800℃ / 3272℉ (depending on the workpiece and coil material) | Product Dimensions | 490*245*440mm |

| Cooling Water | 0.15-0.25MPa 15L/min | Minimum Cooling Water Temperature | 26℃ / 78.8℉ |

PACKING LIST

- Induction Coil (40mm inner diameter, 3 turns, vertical heating) x1

- Foot Pedal x1

- Wire Lugs (40A) x3

- Hose Clamps (22-32) x4

- Screw Nuts (M14-1.5mm internal thread) x2

- Copper Tube (6mm outer diameter, 2m length) x1

- Copper Tubes (8mm outer diameter, 90mm length) x2

- Water Hose (19mm inner diameter, 26mm outer diameter, 6m length) x1

- English Manual x1

- High Frequency Induction Heater Furnace x1

FAQ

1. When the over-temperature light comes on, what should be done?

Let the machine cool down for a certain period and then restart it. Before water enters the machine, ensure that its temperature is below 40°C (104°F). Use only cool and clean water at all times.

2.How to handle the situation when the over-voltage light comes on?

Ensure that the machine is connected to the voltage suitable for its model as per the specifications.

3.How to troubleshoot if the machine fails to power on?

Check the circuit breaker, fuse, power connections, and the power status of the outlet. Make sure all connections are secure and operating properly.

4.How to deal with the machine beeping during startup?

Inspect the connection between the coil and the machine to ensure proper installation. Ensure that the coil is positioned correctly, without excessive turns or improper coverage.

WARNING

1.Always ensure proper grounding of the machine.

2.Maintain a clean and debris-free environment around the machine.

3.Position the heater on a stable and level surface.

4.Utilize original manufacturer parts for optimal safety and performance.

OTHER MODELS

| Output Power | Power Supply | Non-handheld Type | Handheld Type |

|---|---|---|---|

| 15kW | Single Phase 110V or 220V | USS-HFIH00001(16:1 Turn Ratio) | USS-HFIH00015 |

| Single Phase 110V or 220V | USS-HFIH00011(16:2 Turn Ratio) | ||

| 25kW | Three Phase 380V | USS-HFIH00003-380V(18:1 Turn Ratio) | USS-HFIH00016 |

| Three Phase 480V | USS-HFIH00003-480V(18:1 Turn Ratio) | ||

| 25kW | Three Phase 380V | USS-HFIH00012-380V(18:2 Turn Ratio) | |

| Three Phase 480V | USS-HFIH00012-480V(18:2 Turn Ratio) | ||

| 35kW | Three Phase 380V or 480V | USS-HFIH00004(18:1 Turn Ratio) | USS-HFIH00018 |

| 40kW | Three Phase 380V or 480V | USS-HFIH00008(18:1 Turn Ratio) | USS-HFIH00019 |

| 60kW | Three Phase 380V or 480V | USS-HFIH00006(18:1 Turn Ratio) | USS-HFIH00020 |

| 80kW | Three Phase 380V or 480V | USS-HFIH00014(18:1 Turn Ratio) | USS-HFIH00021 |

ACCESSORIES

| Model | Description | |||

|---|---|---|---|---|

| USS-HFIH00001-F | M8 Screw Nut | |||

| USS-HFIH00001-P6 | 6mm Copper Pipe | |||

| USS-HFIH00001-P8 | 8mm Copper Pipe | |||

| USS-HFIH00002 | Foot Pedal Switch | |||

| USS-HFIH00001-CLAMP | Clamp, pack of 4 | |||

| USS-HFIH00001-FUSE | Fuse, pack of 3 | |||

| USS-HFIH00001-COIL | Standard coil (inner diameter 40mm, 3 turns) | |||

HOW TO CHOOSE PRODUCTS ACCORDING TO DIFFERENT USES

| Heating Type | Application Range | Frequency Selection | Power Selection |

|---|---|---|---|

| Brazing | Composite welding of drill bits, turning tools, reamers, milling cutters, drill bits, etc., and different materials such as the bottom of stainless steel pans. | Principle: The larger the welding volume, the lower the frequency should be. For tools with a volume smaller than 30*30*30mm³, high frequency can be used; for those larger than 30*30*30mm³, medium frequency should be applied. | Determined according to the specific shape, material, and solder of the workpiece. |

| Workpiece Through-heating | Hot forging and hot rolling of fasteners, standard parts, auto parts, hardware tools, rigging, twist drills, etc. | Principle: The larger the diameter of the workpiece, the lower the frequency should be. For example: Φ20mm and above, medium frequency (1 - 20KHZ); Φ5mm - 20mm, high frequency (20 - 100KHZ); Φ5mm and below, ultra-high frequency (100 - 500KHZ). | Select the appropriate power according to the production efficiency. The higher the power, the faster the speed. For specific details, consult the company's technical personnel. |

| Heat Treatment | Heat treatment of shafts, gears, sprockets, machine tool guide accessories, annealing of metal wire, hydraulic accessories, auto parts, knives, scissors, pliers, annealing of stainless steel pans, etc. | Principle: The shallower the hardened layer required for the workpiece, the higher the frequency should be. For example: below 1mm, ultra-high frequency 100 - 500KHZ; 1 - 2.5mm, super audio frequency 20 - 100KHZ; 2.5mm and above, medium frequency 1 - 20KHZ. | Comprehensively consider the shape of the workpiece, quenching method, quenching hardness, hardened layer requirements, and material. For specific details, consult the company's technical personnel. |

| Melting | Precious metals such as gold, silver, copper, lead, etc. | Usually medium frequency is selected, and high frequency can be selected for small capacity. | Determined according to the specific furnace and production efficiency. |

| Others | Heating and laminating of aluminum-plastic pipes, steel-plastic pipes, cables, wires; aluminum foil sealing used in the food, beverage, and pharmaceutical industries. | Determined according to the specific situation. | Determined according to the production speed, material, and temperature. |

| Special Functions and Supporting Equipment. | Such as dual-frequency equipment, multi-load matching type (double-head, multi-tap), automatic control type, one-to-two, bridge oil pipeline elbow, constant power and constant current, soft connection inductor. |

Download user manual here

INTRODUCTION

This High Frequency Induction Heater enables efficient metalworking by generating electrical currents within conductors like gold, silver, copper, and aluminum, creating precise heat for melting. It offers a constant and stable working temperature, ensuring excellent results.With remarkable features, it has low energy consumption yet high output power, consuming only half the power of traditional electron tube high frequency induction heaters under the same conditions. The 100% load design allows for continuous 24-hour operation.Equipped with the latest MOSFET and IGBT power units and current frequency control standards, it simplifies manual operation. The infrared temperature detector enhances heating quality and automatically controls the temperature. Additionally, the built-in status displays improve reliability and sustainability.

WHY ARE MORE PEOPLE CHOOSING HIGH-FREQUENCY HEATERS?

THE MACHINE CAN BE APPLIED IN A VARIETY OF HEAT TREATMENT SCENARIOS

|

|

|

SPECIFICATIONS

| Model | USS-HFIH00001 | Cooling Water Temperature Protection Point | 40°C/104°F |

|---|---|---|---|

| Power Supply | Single phase 110V or 220V | Output Power | 15kW |

| Fluctuating Frequency | 30-80kHz | Interrupting Rating | 40A |

| Turns Ratio (ratio of primary coil turns to secondary coil turns) | 14:1 | Net Weight | 17Kg |

| Output Current | 200-600A | Time Setting | 1-99 seconds |

| Maximum Heating Temperature | up to 1800℃ / 3272℉ (depending on the workpiece and coil material) | Product Dimensions | 490*245*440mm |

| Cooling Water | 0.15-0.25MPa 15L/min | Minimum Cooling Water Temperature | 26℃ / 78.8℉ |

FAQ

1. When the over-temperature light comes on, what should be done?

Let the machine cool down for a certain period and then restart it. Before water enters the machine, ensure that its temperature is below 40°C (104°F). Use only cool and clean water at all times.

2.How to handle the situation when the over-voltage light comes on?

Ensure that the machine is connected to the voltage suitable for its model as per the specifications.

3.How to troubleshoot if the machine fails to power on?

Check the circuit breaker, fuse, power connections, and the power status of the outlet. Make sure all connections are secure and operating properly.

4.How to deal with the machine beeping during startup?

Inspect the connection between the coil and the machine to ensure proper installation. Ensure that the coil is positioned correctly, without excessive turns or improper coverage.

WARNING

1.Always ensure proper grounding of the machine.

2.Maintain a clean and debris-free environment around the machine.

3.Position the heater on a stable and level surface.

4.Utilize original manufacturer parts for optimal safety and performance.

PACKING LIST

- Induction Coil (40mm inner diameter, 3 turns, vertical heating) x1

- Foot Pedal x1

- Wire Lugs (40A) x3

- Hose Clamps (22-32) x4

- Screw Nuts (M14-1.5mm internal thread) x2

- Copper Tube (6mm outer diameter, 2m length) x1

- Copper Tubes (8mm outer diameter, 90mm length) x2

- Water Hose (19mm inner diameter, 26mm outer diameter, 6m length) x1

- English Manual x1

OTHER MODELS

| Output Power | Power Supply | Non-handheld Type | Handheld Type |

|---|---|---|---|

| 15kW | Single Phase 110V or 220V | USS-HFIH00001(16:1 Turn Ratio) | USS-HFIH00015 |

| Single Phase 110V or 220V | USS-HFIH00011(16:2 Turn Ratio) | ||

| 25kW | Three Phase 380V | USS-HFIH00003-380V(18:1 Turn Ratio) | USS-HFIH00016 |

| Three Phase 480V | USS-HFIH00003-480V(18:1 Turn Ratio) | ||

| 25kW | Three Phase 380V | USS-HFIH00012-380V(18:2 Turn Ratio) | |

| Three Phase 480V | USS-HFIH00012-480V(18:2 Turn Ratio) | ||

| 35kW | Three Phase 380V or 480V | USS-HFIH00004(18:1 Turn Ratio) | USS-HFIH00018 |

| 40kW | Three Phase 380V or 480V | USS-HFIH00008(18:1 Turn Ratio) | USS-HFIH00019 |

| 60kW | Three Phase 380V or 480V | USS-HFIH00006(18:1 Turn Ratio) | USS-HFIH00020 |

| 80kW | Three Phase 380V or 480V | USS-HFIH00014(18:1 Turn Ratio) | USS-HFIH00021 |

ACCESSORIES

| Model | Description | |||

|---|---|---|---|---|

| USS-HFIH00001-F | M8 Screw Nut | |||

| USS-HFIH00001-P6 | 6mm Copper Pipe | |||

| USS-HFIH00001-P8 | 8mm Copper Pipe | |||

| USS-HFIH00002 | Foot Pedal Switch | |||

HOW TO CHOOSE PRODUCTS ACCORDING TO DIFFERENT USES

| Heating Type | Application Range | Frequency Selection | Power Selection |

|---|---|---|---|

| Brazing | Composite welding of drill bits, turning tools, reamers, milling cutters, drill bits, etc., and different materials such as the bottom of stainless steel pans. | Principle: The larger the welding volume, the lower the frequency should be. For tools with a volume smaller than 30*30*30mm³, high frequency can be used; for those larger than 30*30*30mm³, medium frequency should be applied. | Determined according to the specific shape, material, and solder of the workpiece. |

| Workpiece Through-heating | Hot forging and hot rolling of fasteners, standard parts, auto parts, hardware tools, rigging, twist drills, etc. | Principle: The larger the diameter of the workpiece, the lower the frequency should be. For example: Φ20mm and above, medium frequency (1 - 20KHZ); Φ5mm - 20mm, high frequency (20 - 100KHZ); Φ5mm and below, ultra-high frequency (100 - 500KHZ). | Select the appropriate power according to the production efficiency. The higher the power, the faster the speed. For specific details, consult the company's technical personnel. |

| Heat Treatment | Heat treatment of shafts, gears, sprockets, machine tool guide accessories, annealing of metal wire, hydraulic accessories, auto parts, knives, scissors, pliers, annealing of stainless steel pans, etc. | Principle: The shallower the hardened layer required for the workpiece, the higher the frequency should be. For example: below 1mm, ultra-high frequency 100 - 500KHZ; 1 - 2.5mm, super audio frequency 20 - 100KHZ; 2.5mm and above, medium frequency 1 - 20KHZ. | Comprehensively consider the shape of the workpiece, quenching method, quenching hardness, hardened layer requirements, and material. For specific details, consult the company's technical personnel. |

| Melting | Precious metals such as gold, silver, copper, lead, etc. | Usually medium frequency is selected, and high frequency can be selected for small capacity. | Determined according to the specific furnace and production efficiency. |

| Others | Heating and laminating of aluminum-plastic pipes, steel-plastic pipes, cables, wires; aluminum foil sealing used in the food, beverage, and pharmaceutical industries. | Determined according to the specific situation | Determined according to the production speed, material, and temperature. |

| Special Functions and Supporting Equipment | Such as dual-frequency equipment, multi-load matching type (double-head, multi-tap), automatic control type, one-to-two, bridge oil pipeline elbow, constant power and constant current, soft connection inductor. |

Download user manual here