INTRODUCTION

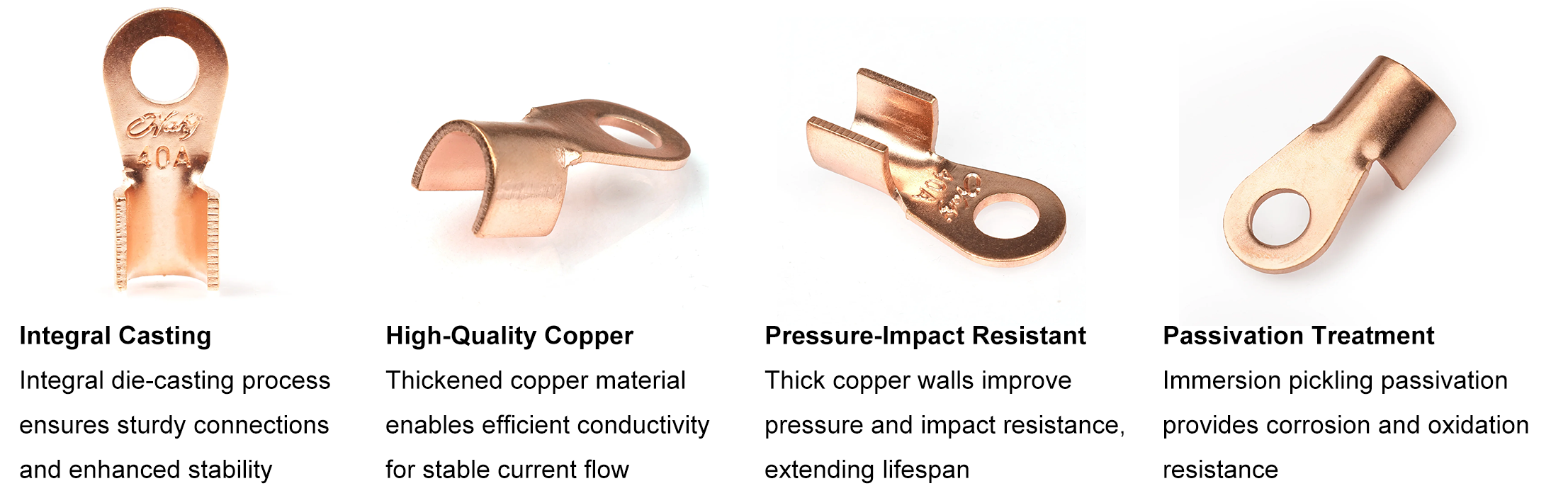

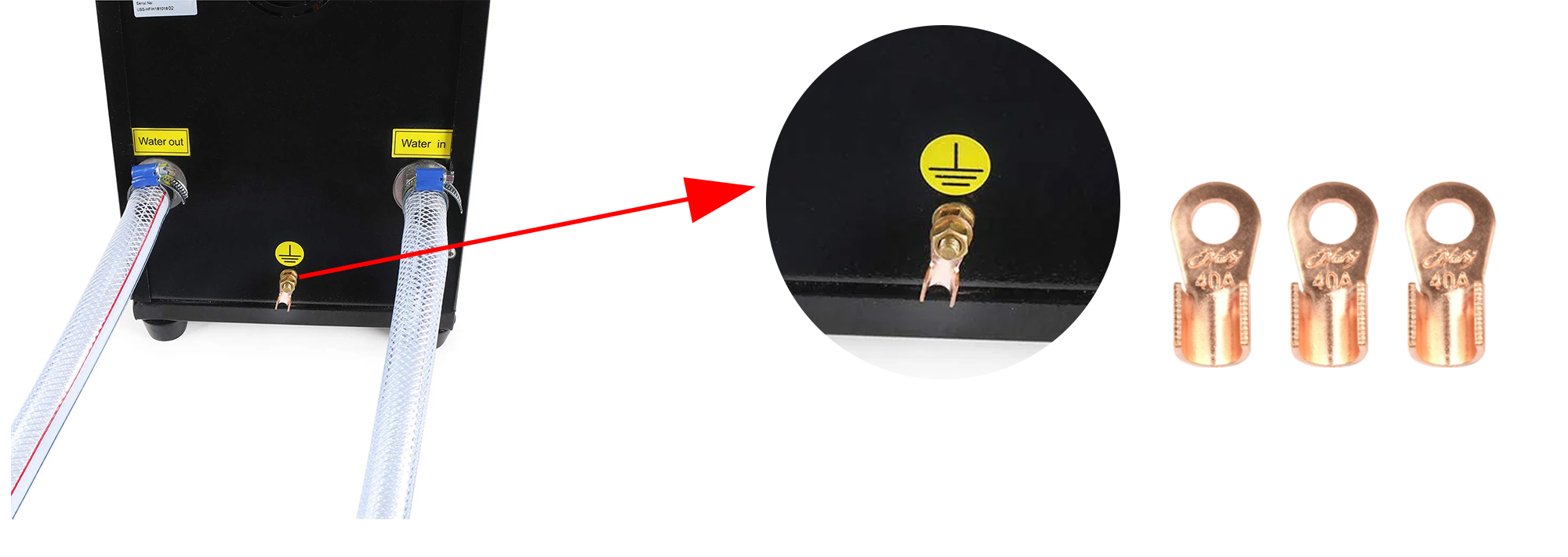

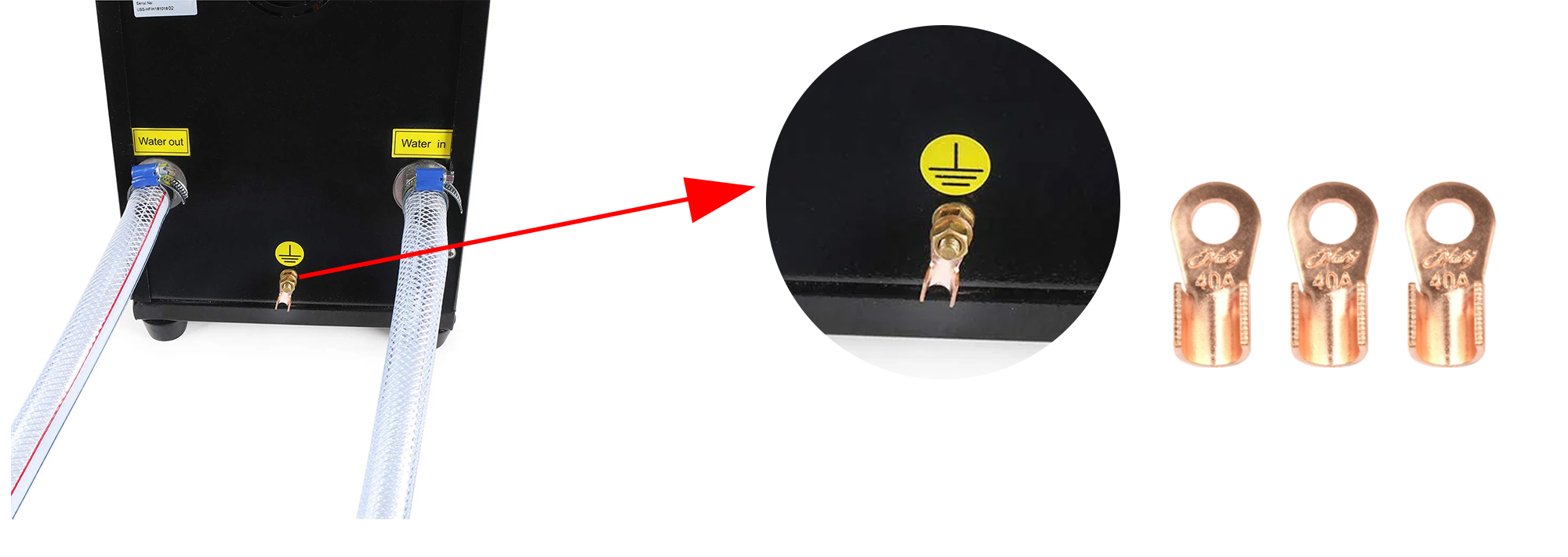

This product stands out with its exceptional craftsmanship and performance. Employing an integral die-casting process, it achieves sturdy connections, uniform wall thickness, and enhanced durability, ensuring reliable structural stability. Constructed from thickened high-quality copper, it provides efficient conductivity, enabling stable and efficient current transmission. The thick copper walls endow it with remarkable pressure and impact resistance, significantly improving its compressive strength and extending its service life. Its surface, treated with immersion pickling passivation, resists corrosion and oxidation, maintaining long-term durability. Additionally, with firm wire pressing and tight wiring, this product offers outstanding durability and long-lasting performance, making it an ideal choice for extended use.

FEATURES

HOW TO USE

OTHER MODELS

| Output Power | Turns Ratio | Power Supply | Non-handheld Type | Handheld Type |

|---|---|---|---|---|

| 15kW | 16:1 | Single Phase 110V or 220V | USS-HFIH00001 | USS-HFIH00015 |

| 16:2 | Single Phase 110V or 220V | USS-HFIH00011 | ||

| 25kW | 18:1 | Three Phase 380V | USS-HFIH00003-380V | USS-HFIH00016 |

| Three Phase 480V | USS-HFIH00003-480V | |||

| 25kW | 18:2 | Three Phase 380V | USS-HFIH00012-380V | |

| Three Phase 480V | USS-HFIH00012-480V | |||

| 35kW | 18:1 | Three Phase 380V or 480V | USS-HFIH00004 | USS-HFIH00018 |

| 40kW | 18:1 | Three Phase 380V or 480V | USS-HFIH00008 | USS-HFIH00019 |

| 60kW | 18:1 | Three Phase 380V or 480V | USS-HFIH00006 | USS-HFIH00020 |

| 80kW | 18:1 | Three Phase 380V or 480V | USS-HFIH00014 | USS-HFIH00021 |

ACCESSORIES

| Model | Description | |||

|---|---|---|---|---|

| USS-HFIH00001-F | M8 Screw Nut | |||

| USS-HFIH00001-P6 | 6mm Copper Pipe | |||

| USS-HFIH00001-P8 | 8mm Copper Pipe | |||

| USS-HFIH00002 | Foot Pedal Switch | |||

| USS-HFIH00001-CLAMP | Clamp, pack of 4 | |||

| USS-HFIH00001-FUSE | Fuse, pack of 3 | |||

| USS-HFIH00001-COIL | Standard coil (inner diameter 40mm, 3 turns) | |||

HOW TO CHOOSE PRODUCTS ACCORDING TO DIFFERENT USES

| Heating Type | Application Range | Frequency Selection | Power Selection |

|---|---|---|---|

| Brazing | Composite welding of drill bits, turning tools, reamers, milling cutters, drill bits, etc., and different materials such as the bottom of stainless steel pans. | Principle: The larger the welding volume, the lower the frequency should be. For tools with a volume smaller than 30*30*30mm³, high frequency can be used; for those larger than 30*30*30mm³, medium frequency should be applied. | Determined according to the specific shape, material, and solder of the workpiece. |

| Workpiece Through-heating | Hot forging and hot rolling of fasteners, standard parts, auto parts, hardware tools, rigging, twist drills, etc. | Principle: The larger the diameter of the workpiece, the lower the frequency should be. For example: Φ20mm and above, medium frequency (1 - 20KHZ); Φ5mm - 20mm, high frequency (20 - 100KHZ); Φ5mm and below, ultra-high frequency (100 - 500KHZ). | Select the appropriate power according to the production efficiency. The higher the power, the faster the speed. For specific details, consult the company's technical personnel. |

| Heat Treatment | Heat treatment of shafts, gears, sprockets, machine tool guide accessories, annealing of metal wire, hydraulic accessories, auto parts, knives, scissors, pliers, annealing of stainless steel pans, etc. | Principle: The shallower the hardened layer required for the workpiece, the higher the frequency should be. For example: below 1mm, ultra-high frequency 100 - 500KHZ; 1 - 2.5mm, super audio frequency 20 - 100KHZ; 2.5mm and above, medium frequency 1 - 20KHZ. | Comprehensively consider the shape of the workpiece, quenching method, quenching hardness, hardened layer requirements, and material. For specific details, consult the company's technical personnel. |

| Melting | Precious metals such as gold, silver, copper, lead, etc. | Usually medium frequency is selected, and high frequency can be selected for small capacity. | Determined according to the specific furnace and production efficiency. |

| Others | Heating and laminating of aluminum-plastic pipes, steel-plastic pipes, cables, wires; aluminum foil sealing used in the food, beverage, and pharmaceutical industries. | Determined according to the specific situation. | Determined according to the production speed, material, and temperature. |

| Special Functions and Supporting Equipment. | Such as dual-frequency equipment, multi-load matching type (double-head, multi-tap), automatic control type, one-to-two, bridge oil pipeline elbow, constant power and constant current, soft connection inductor. |

Download user manual here

INTRODUCTION

This product stands out with its exceptional craftsmanship and performance. Employing an integral die-casting process, it achieves sturdy connections, uniform wall thickness, and enhanced durability, ensuring reliable structural stability. Constructed from thickened high-quality copper, it provides efficient conductivity, enabling stable and efficient current transmission. The thick copper walls endow it with remarkable pressure and impact resistance, significantly improving its compressive strength and extending its service life. Its surface, treated with immersion pickling passivation, resists corrosion and oxidation, maintaining long-term durability. Additionally, with firm wire pressing and tight wiring, this product offers outstanding durability and long-lasting performance, making it an ideal choice for extended use.

FEATURES

HOW TO USE

OTHER MODELS

| Output Power | Turns Ratio | Power Supply | Non-handheld Type | Handheld Type |

|---|---|---|---|---|

| 15kW | 16:1 | Single Phase 110V or 220V | USS-HFIH00001 | USS-HFIH00015 |

| 16:2 | Single Phase 110V or 220V | USS-HFIH00011 | ||

| 25kW | 18:1 | Three Phase 380V | USS-HFIH00003-380V | USS-HFIH00016 |

| Three Phase 480V | USS-HFIH00003-480V | |||

| 35kW | 18:1 | Three Phase 380V or 480V | USS-HFIH00004 | USS-HFIH00018 |

| 40kW | 18:1 | Three Phase 380V or 480V | USS-HFIH00008 | USS-HFIH00019 |

| 60kW | 18:1 | Three Phase 380V or 480V | USS-HFIH00006 | USS-HFIH00020 |

| 80kW | 18:1 | Three Phase 380V or 480V | USS-HFIH00014 | USS-HFIH00021 |

ACCESSORIES

| Model | Description | |||

|---|---|---|---|---|

| USS-HFIH00001-F | M8 Screw Nut | |||

| USS-HFIH00001-P6 | 6mm Copper Pipe | |||

| USS-HFIH00001-P8 | 8mm Copper Pipe | |||

| USS-HFIH00002 | Foot Pedal Switch | |||

HOW TO CHOOSE PRODUCTS ACCORDING TO DIFFERENT USES

| Heating Type | Application Range | Frequency Selection | Power Selection |

|---|---|---|---|

| Brazing | Composite welding of drill bits, turning tools, reamers, milling cutters, drill bits, etc., and different materials such as the bottom of stainless steel pans. | Principle: The larger the welding volume, the lower the frequency should be. For tools with a volume smaller than 30*30*30mm³, high frequency can be used; for those larger than 30*30*30mm³, medium frequency should be applied. | Determined according to the specific shape, material, and solder of the workpiece. |

| Workpiece Through-heating | Hot forging and hot rolling of fasteners, standard parts, auto parts, hardware tools, rigging, twist drills, etc. | Principle: The larger the diameter of the workpiece, the lower the frequency should be. For example: Φ20mm and above, medium frequency (1 - 20KHZ); Φ5mm - 20mm, high frequency (20 - 100KHZ); Φ5mm and below, ultra-high frequency (100 - 500KHZ). | Select the appropriate power according to the production efficiency. The higher the power, the faster the speed. For specific details, consult the company's technical personnel. |

| Heat Treatment | Heat treatment of shafts, gears, sprockets, machine tool guide accessories, annealing of metal wire, hydraulic accessories, auto parts, knives, scissors, pliers, annealing of stainless steel pans, etc. | Principle: The shallower the hardened layer required for the workpiece, the higher the frequency should be. For example: below 1mm, ultra-high frequency 100 - 500KHZ; 1 - 2.5mm, super audio frequency 20 - 100KHZ; 2.5mm and above, medium frequency 1 - 20KHZ. | Comprehensively consider the shape of the workpiece, quenching method, quenching hardness, hardened layer requirements, and material. For specific details, consult the company's technical personnel. |

| Melting | Precious metals such as gold, silver, copper, lead, etc. | Usually medium frequency is selected, and high frequency can be selected for small capacity. | Determined according to the specific furnace and production efficiency. |

| Others | Heating and laminating of aluminum-plastic pipes, steel-plastic pipes, cables, wires; aluminum foil sealing used in the food, beverage, and pharmaceutical industries. | Determined according to the specific situation | Determined according to the production speed, material, and temperature. |

| Special Functions and Supporting Equipment | Such as dual-frequency equipment, multi-load matching type (double-head, multi-tap), automatic control type, one-to-two, bridge oil pipeline elbow, constant power and constant current, soft connection inductor. |

Download user manual here