INTRODUCTION

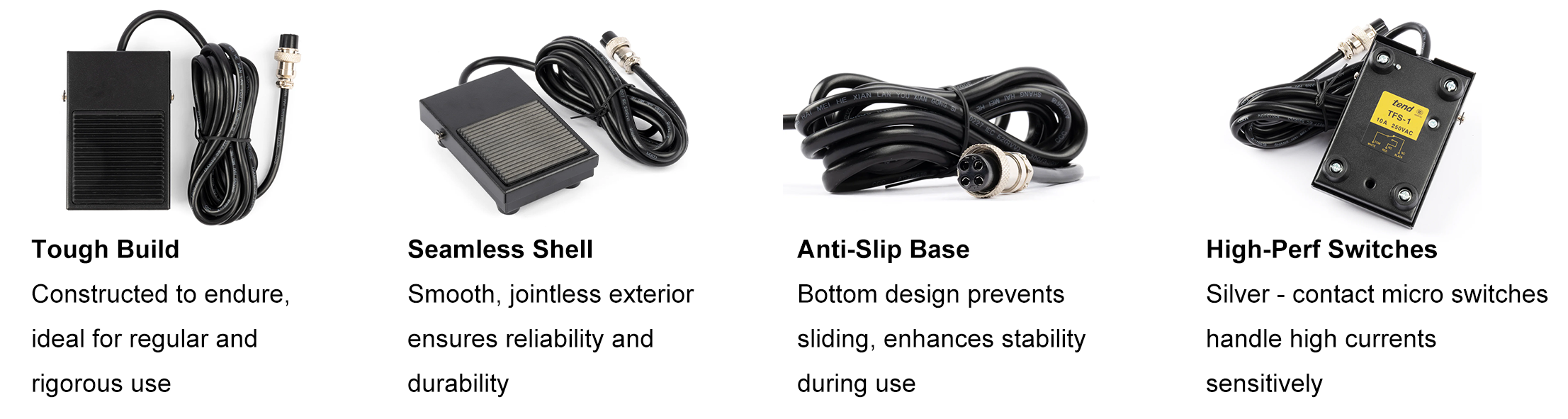

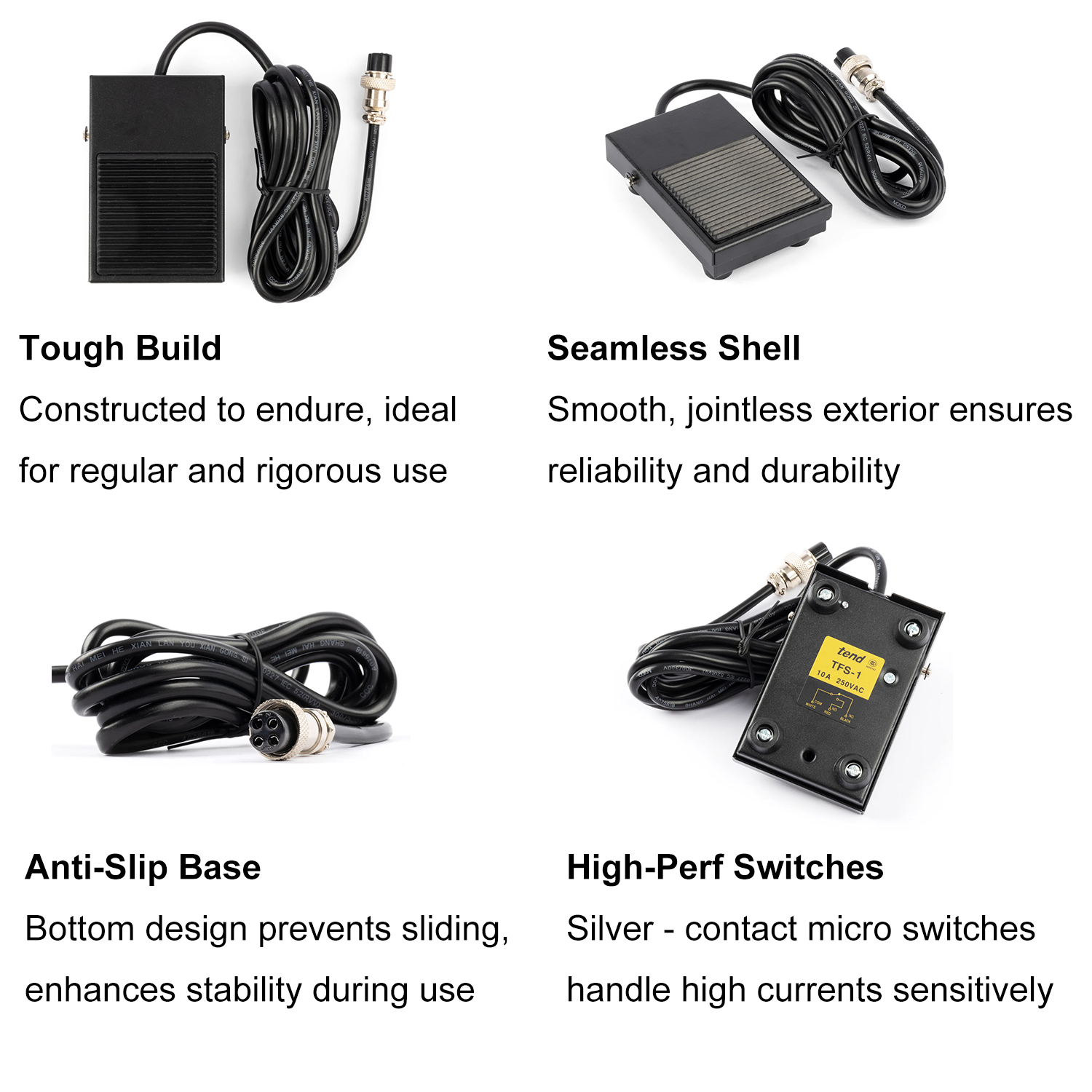

This foot pedal switch features a durable and sturdy seamless shell design, making it suitable for frequent use. Its bottom anti-slip design enhances stability during operation, while corrosion-resistant silver contact micro switches ensure high sensitivity and can handle high currents. Made with flame-retardant materials, this device offers safe and stable operation. The smooth surface design is resistant to damage, ensuring long-lasting quality performance.

FEATURES

HOW TO USE

OTHER MODELS

| Output Power | Turns Ratio | Power Supply | Non-handheld Type | Handheld Type |

|---|---|---|---|---|

| 15kW | 16:1 | Single Phase 110V or 220V | USS-HFIH00001 | USS-HFIH00015 |

| 16:2 | Single Phase 110V or 220V | USS-HFIH00011 | ||

| 25kW | 18:1 | Three Phase 380V | USS-HFIH00003-380V | USS-HFIH00016 |

| Three Phase 480V | USS-HFIH00003-480V | |||

| 25kW | 18:2 | Three Phase 380V | USS-HFIH00012-380V | |

| Three Phase 480V | USS-HFIH00012-480V | |||

| 35kW | 18:1 | Three Phase 380V or 480V | USS-HFIH00004 | USS-HFIH00018 |

| 40kW | 18:1 | Three Phase 380V or 480V | USS-HFIH00008 | USS-HFIH00019 |

| 60kW | 18:1 | Three Phase 380V or 480V | USS-HFIH00006 | USS-HFIH00020 |

| 80kW | 18:1 | Three Phase 380V or 480V | USS-HFIH00014 | USS-HFIH00021 |

ACCESSORIES

| Model | Description | |||

|---|---|---|---|---|

| USS-HFIH00001-F | M8 Screw Nut | |||

| USS-HFIH00001-P6 | 6mm Copper Pipe | |||

| USS-HFIH00001-P8 | 8mm Copper Pipe | |||

| USS-HFIH00002 | Foot Pedal Switch | |||

| USS-HFIH00001-CLAMP | Clamp, pack of 4 | |||

| USS-HFIH00001-FUSE | Fuse, pack of 3 | |||

| USS-HFIH00001-COIL | Standard coil (inner diameter 40mm, 3 turns) | |||

HOW TO CHOOSE PRODUCTS ACCORDING TO DIFFERENT USES

| Heating Type | Application Range | Frequency Selection | Power Selection |

|---|---|---|---|

| Brazing | Composite welding of drill bits, turning tools, reamers, milling cutters, drill bits, etc., and different materials such as the bottom of stainless steel pans. | Principle: The larger the welding volume, the lower the frequency should be. For tools with a volume smaller than 30*30*30mm³, high frequency can be used; for those larger than 30*30*30mm³, medium frequency should be applied. | Determined according to the specific shape, material, and solder of the workpiece. |

| Workpiece Through-heating | Hot forging and hot rolling of fasteners, standard parts, auto parts, hardware tools, rigging, twist drills, etc. | Principle: The larger the diameter of the workpiece, the lower the frequency should be. For example: Φ20mm and above, medium frequency (1 - 20KHZ); Φ5mm - 20mm, high frequency (20 - 100KHZ); Φ5mm and below, ultra-high frequency (100 - 500KHZ). | Select the appropriate power according to the production efficiency. The higher the power, the faster the speed. For specific details, consult the company's technical personnel. |

| Heat Treatment | Heat treatment of shafts, gears, sprockets, machine tool guide accessories, annealing of metal wire, hydraulic accessories, auto parts, knives, scissors, pliers, annealing of stainless steel pans, etc. | Principle: The shallower the hardened layer required for the workpiece, the higher the frequency should be. For example: below 1mm, ultra-high frequency 100 - 500KHZ; 1 - 2.5mm, super audio frequency 20 - 100KHZ; 2.5mm and above, medium frequency 1 - 20KHZ. | Comprehensively consider the shape of the workpiece, quenching method, quenching hardness, hardened layer requirements, and material. For specific details, consult the company's technical personnel. |

| Melting | Precious metals such as gold, silver, copper, lead, etc. | Usually medium frequency is selected, and high frequency can be selected for small capacity. | Determined according to the specific furnace and production efficiency. |

| Others | Heating and laminating of aluminum-plastic pipes, steel-plastic pipes, cables, wires; aluminum foil sealing used in the food, beverage, and pharmaceutical industries. | Determined according to the specific situation. | Determined according to the production speed, material, and temperature. |

| Special Functions and Supporting Equipment. | Such as dual-frequency equipment, multi-load matching type (double-head, multi-tap), automatic control type, one-to-two, bridge oil pipeline elbow, constant power and constant current, soft connection inductor. |

Download user manual here

INTRODUCTION

This foot pedal switch features a durable and sturdy seamless shell design, making it suitable for frequent use. Its bottom anti-slip design enhances stability during operation, while corrosion-resistant silver contact micro switches ensure high sensitivity and can handle high currents. Made with flame-retardant materials, this device offers safe and stable operation. The smooth surface design is resistant to damage, ensuring long-lasting quality performance.

FEATURES

HOW TO USE

OTHER MODELS

| Output Power | Turns Ratio | Power Supply | Non-handheld Type | Handheld Type |

|---|---|---|---|---|

| 15kW | 16:1 | Single Phase 110V or 220V | USS-HFIH00001 | USS-HFIH00015 |

| 16:2 | Single Phase 110V or 220V | USS-HFIH00011 | ||

| 25kW | 18:1 | Three Phase 380V | USS-HFIH00003-380V | USS-HFIH00016 |

| Three Phase 480V | USS-HFIH00003-480V | |||

| 35kW | 18:1 | Three Phase 380V or 480V | USS-HFIH00004 | USS-HFIH00018 |

| 40kW | 18:1 | Three Phase 380V or 480V | USS-HFIH00008 | USS-HFIH00019 |

| 60kW | 18:1 | Three Phase 380V or 480V | USS-HFIH00006 | USS-HFIH00020 |

| 80kW | 18:1 | Three Phase 380V or 480V | USS-HFIH00014 | USS-HFIH00021 |

ACCESSORIES

| Model | Description | |||

|---|---|---|---|---|

| USS-HFIH00001-F | M8 Screw Nut | |||

| USS-HFIH00001-P6 | 6mm Copper Pipe | |||

| USS-HFIH00001-P8 | 8mm Copper Pipe | |||

| USS-HFIH00002 | Foot Pedal Switch | |||

HOW TO CHOOSE PRODUCTS ACCORDING TO DIFFERENT USES

| Heating Type | Application Range | Frequency Selection | Power Selection |

|---|---|---|---|

| Brazing | Composite welding of drill bits, turning tools, reamers, milling cutters, drill bits, etc., and different materials such as the bottom of stainless steel pans. | Principle: The larger the welding volume, the lower the frequency should be. For tools with a volume smaller than 30*30*30mm³, high frequency can be used; for those larger than 30*30*30mm³, medium frequency should be applied. | Determined according to the specific shape, material, and solder of the workpiece. |

| Workpiece Through-heating | Hot forging and hot rolling of fasteners, standard parts, auto parts, hardware tools, rigging, twist drills, etc. | Principle: The larger the diameter of the workpiece, the lower the frequency should be. For example: Φ20mm and above, medium frequency (1 - 20KHZ); Φ5mm - 20mm, high frequency (20 - 100KHZ); Φ5mm and below, ultra-high frequency (100 - 500KHZ). | Select the appropriate power according to the production efficiency. The higher the power, the faster the speed. For specific details, consult the company's technical personnel. |

| Heat Treatment | Heat treatment of shafts, gears, sprockets, machine tool guide accessories, annealing of metal wire, hydraulic accessories, auto parts, knives, scissors, pliers, annealing of stainless steel pans, etc. | Principle: The shallower the hardened layer required for the workpiece, the higher the frequency should be. For example: below 1mm, ultra-high frequency 100 - 500KHZ; 1 - 2.5mm, super audio frequency 20 - 100KHZ; 2.5mm and above, medium frequency 1 - 20KHZ. | Comprehensively consider the shape of the workpiece, quenching method, quenching hardness, hardened layer requirements, and material. For specific details, consult the company's technical personnel. |

| Melting | Precious metals such as gold, silver, copper, lead, etc. | Usually medium frequency is selected, and high frequency can be selected for small capacity. | Determined according to the specific furnace and production efficiency. |

| Others | Heating and laminating of aluminum-plastic pipes, steel-plastic pipes, cables, wires; aluminum foil sealing used in the food, beverage, and pharmaceutical industries. | Determined according to the specific situation | Determined according to the production speed, material, and temperature. |

| Special Functions and Supporting Equipment | Such as dual-frequency equipment, multi-load matching type (double-head, multi-tap), automatic control type, one-to-two, bridge oil pipeline elbow, constant power and constant current, soft connection inductor. |

Download user manual here